Intelligent management system and intelligent management method

An intelligent management system and intelligent management technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of enterprise inventory backlog, error-prone materials, consumption of manpower and material resources, etc., to improve the efficiency of material preparation and prevent wrong materials. Ability, Manpower Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

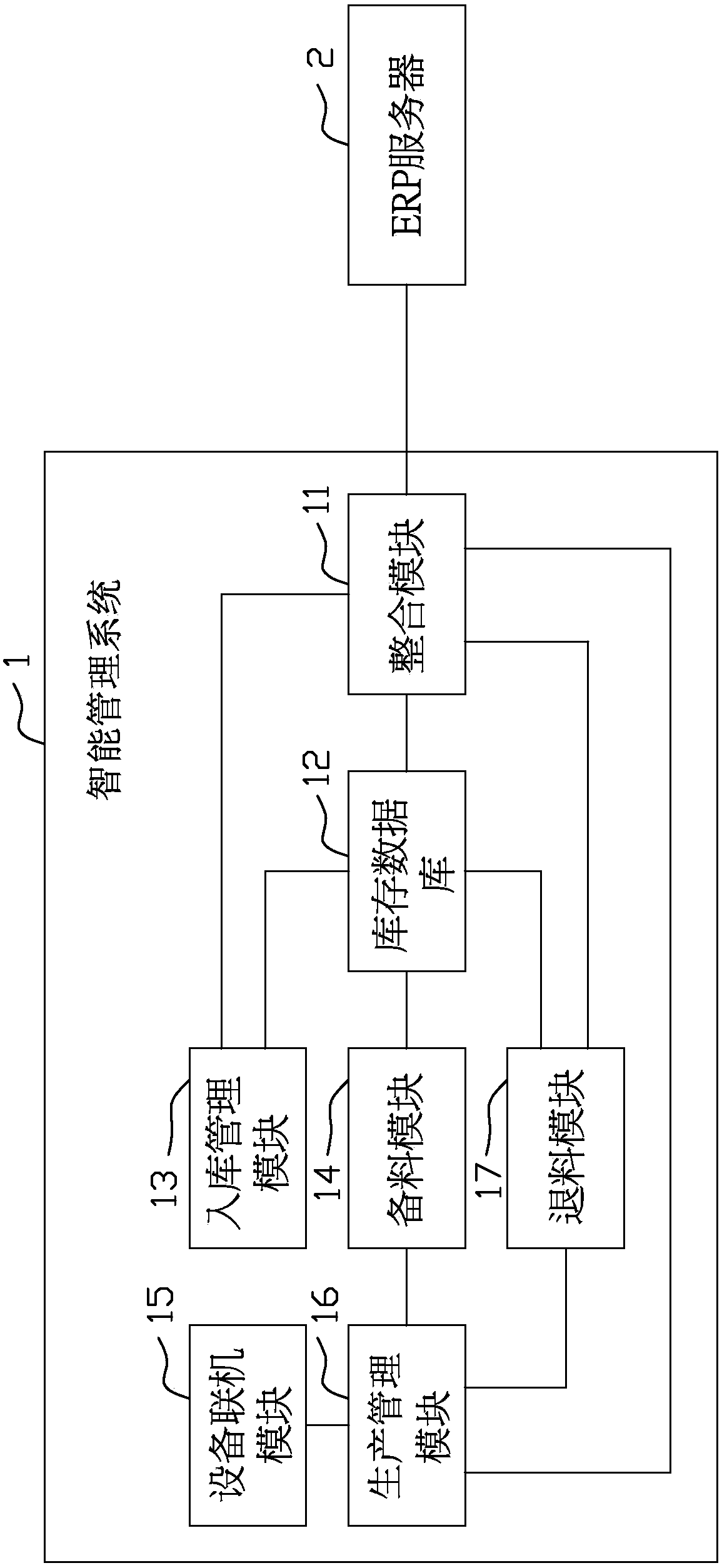

[0034] See figure 1 As shown, the intelligent management system 1 is connected to the ERP server 2 and includes an integration module 11, an inventory database 12, a warehousing management module 13, a material preparation module 14, an equipment online module 15 and a material return module 17.

[0035] The integration module 11 uses DB-link to perform data transmission with the ERP server 2 and defines the transmitted data code. Different formats of the code represent different transmission directions and data types, so as to combine receipts, inventory, work orders, etc. Information is synchronized between the integration module 11 and the ERP server 2. For example, codes starting with 856 and 862 respectively represent information sent from the integration module 11 to the ERP server 2 and sent from the ERP server 2 to the integration module 11 For example, it is defined that 856S means sending an order form information from the ERP server 2 to the integration module 11, 862S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com