Comprehensive optimization method and system for order scheduling of pulping and paper making enterprises

A technology for pulping and papermaking and optimization methods, which is applied to instruments, data processing applications, forecasting, etc., can solve problems such as labor cost, low management cost, low paper conversion cost, complex production scheduling optimization, etc., to improve adaptability, Solve practical optimization problems, the effect of advanced algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

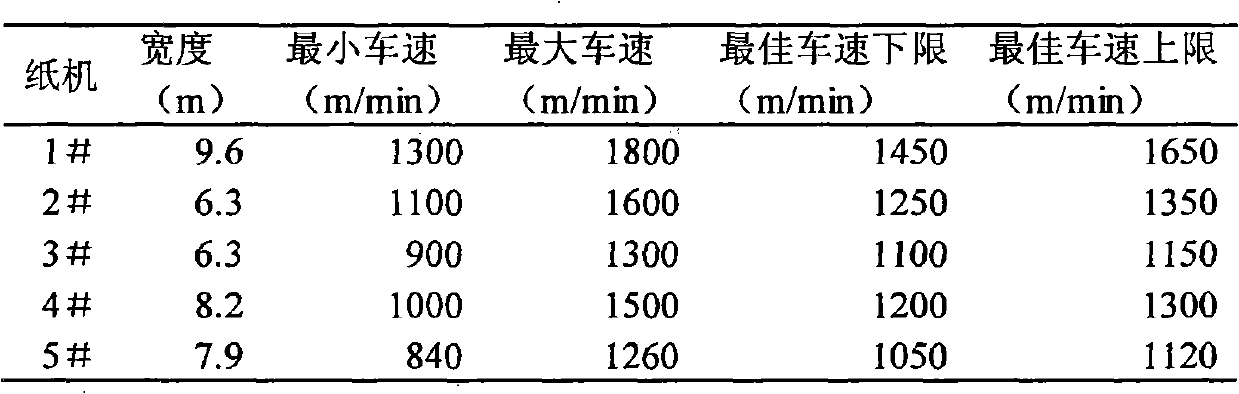

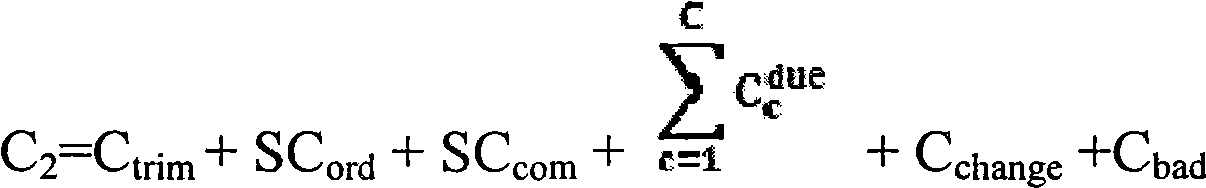

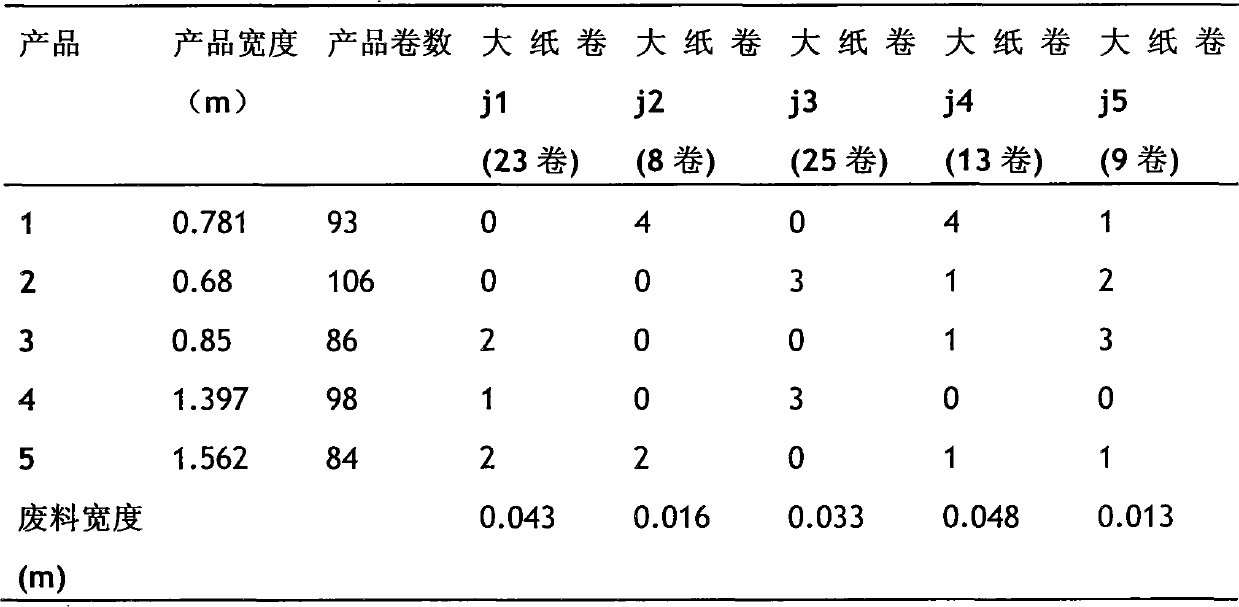

[0047] The system of the present invention is used to optimize the order scheduling, and when the operating conditions of the production equipment are very good, such as figure 2 The system shown does not need to go through the process of scheduling simulation. This example uses image 3 The system shown is illustrated by taking a paper mill with 5 paper machine production lines as an example. The optimization process is as follows: figure 1 As shown, among them, 1#~5# respectively represent the paper machine production lines 1~5 of the paper mill, and the production operation data are shown in Table 1; and Table 2 is the corresponding paper machine stored in the cost database. The empirical data of the paper grade conversion time; the orders received by the paper mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com