Dynamic quality remote monitoring system and method in production of cement concrete

A remote monitoring system, cement concrete technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as dependence on the correctness of test results, waste, test and test data falsification, etc., to reduce the intensity of on-site management work , Improve detection efficiency and improve production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

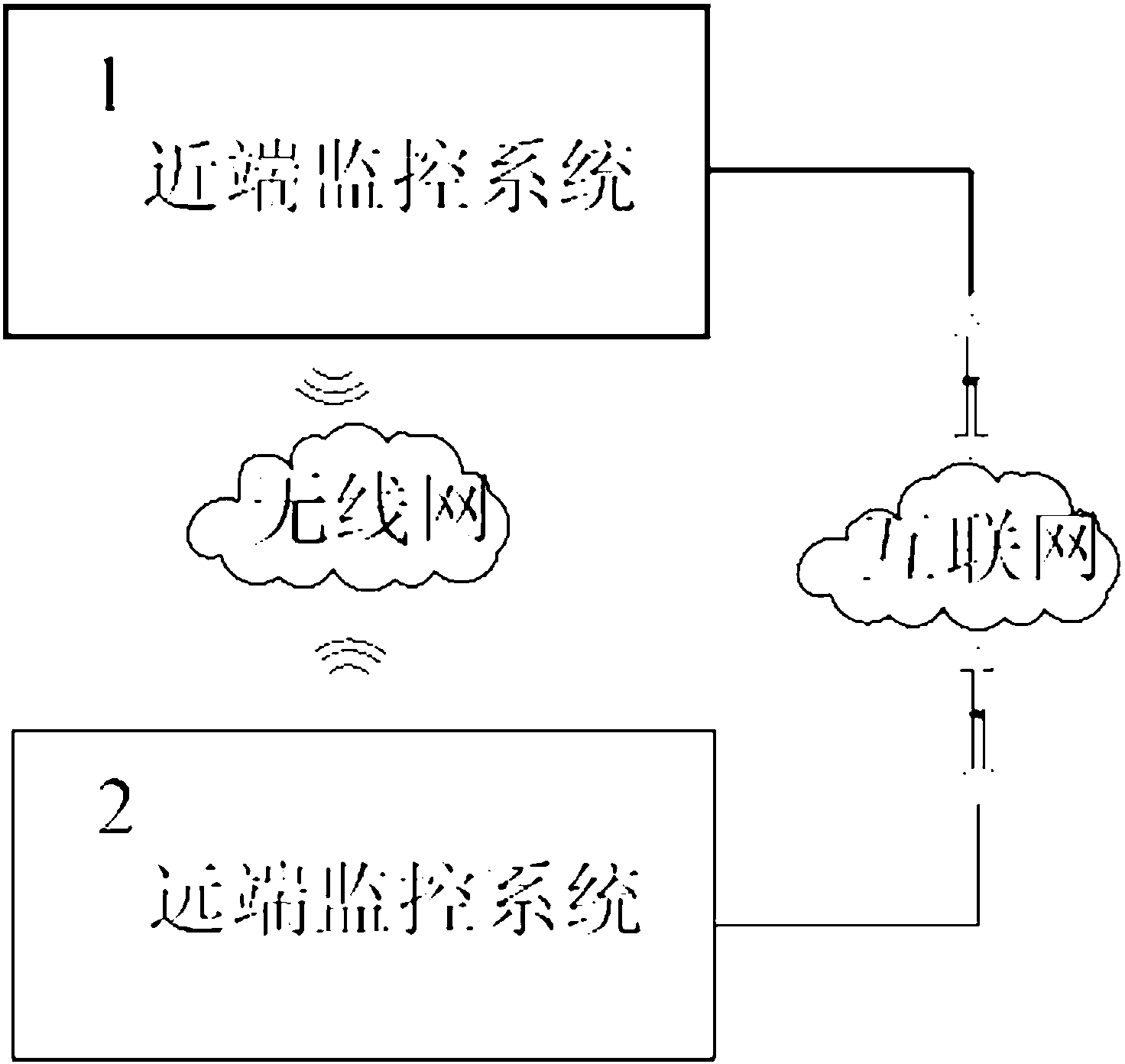

[0043] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the near-end monitoring system 1 configured on the cement concrete mixing site and the remote monitoring system 2 away from the cement concrete mixing site, the near-end monitoring system 1 communicates with the remote monitoring system 2 through a wireless network and the Internet, so that the remote monitoring system 2 can monitor the transitional quality data of the production process of the cement concrete mixing site at any location.

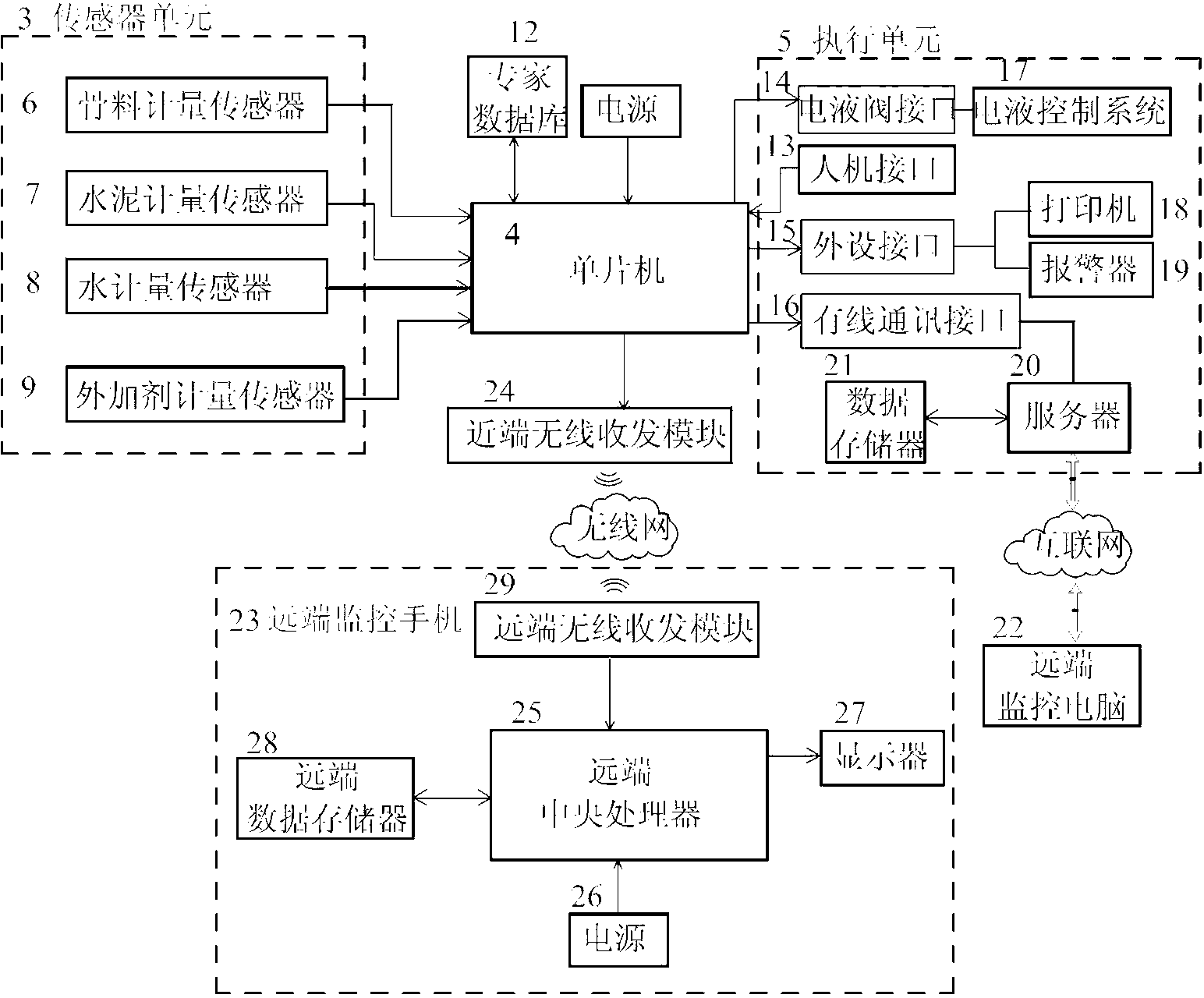

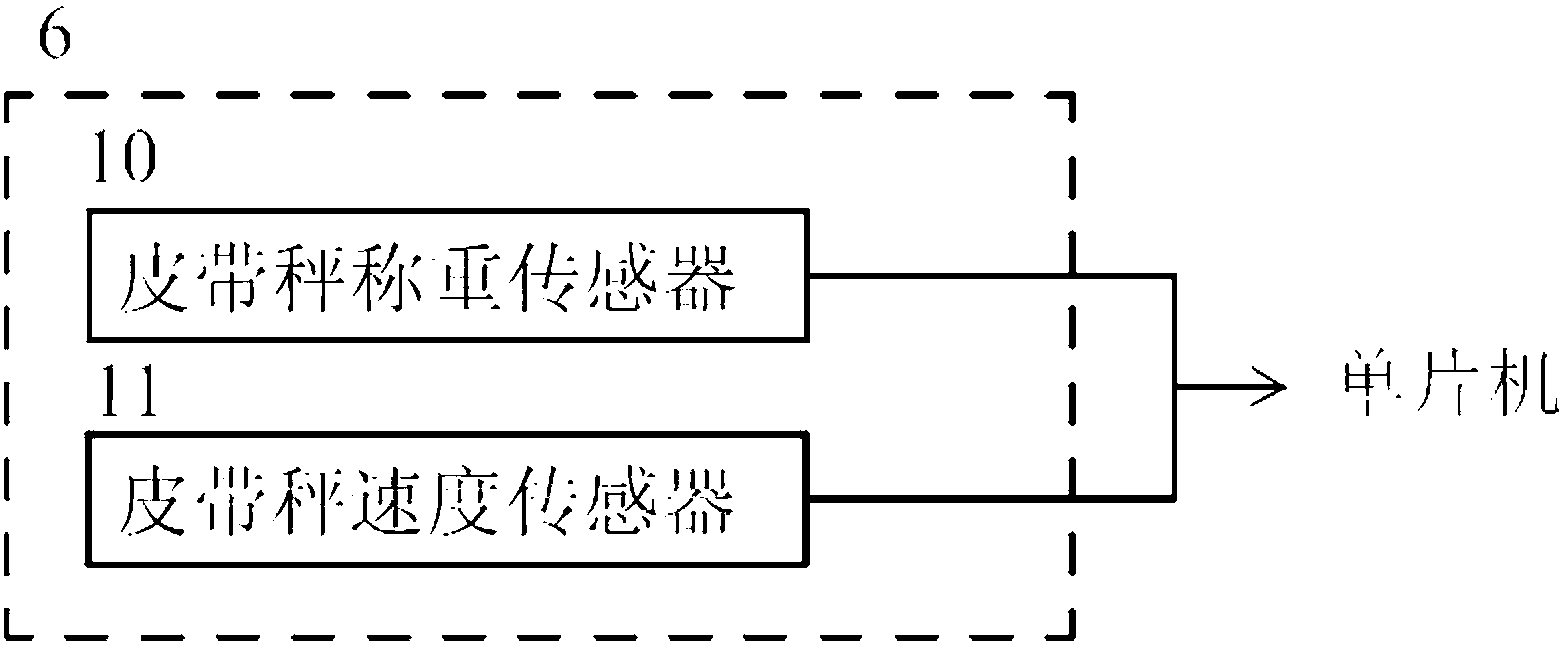

[0044] Among them, such as figure 2As shown, the near-end monitoring system 1 includes a sensor unit 3 for real-time detection of parameters that affect the quality of cement concrete production in the cement concrete production process, and is used to analyze and process the signal detected by the sensor unit 3 and obtain a monitoring result. The resulting single-chip microcomputer 4, the execution uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com