Method for tracking hot rolling production management level graphic rolling line material

A production management and graphic technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problem that production managers cannot remotely monitor the production and equipment conditions of hot rolling lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

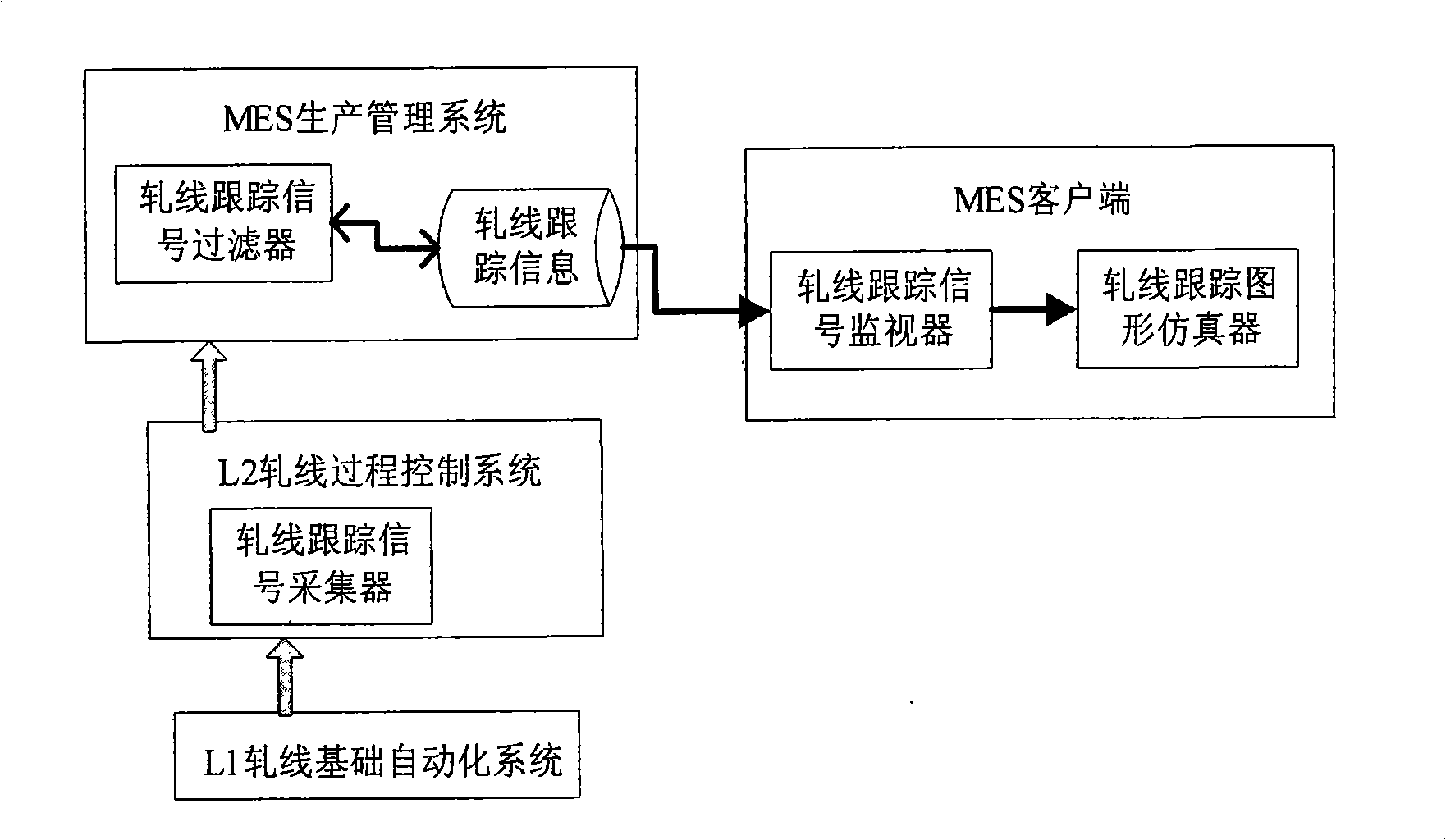

[0014] Such as figure 1 : Shown, the method for the hot-rolled MES graphical material tracking provided by the present invention comprises:

[0015] a. Rolling line signal tracking step: through the rolling line tracking signal collector, select and determine the representative key position signal tracking point of the rolling line from the exit of the heating furnace to the end of coiling, and L2 will collect the tracking signal on the process computer and communicate it The software is sent to the production management computer MES.

[0016] b. Rolling line signal filtering step: through the rolling line tracking signal filter, MES receives the tracking signal sent by the process computer, and analyzes and processes the tracking signal. Save effective tracking information to the database, and record tracking information such as rolling interval time (more than a certain range is regarded as downtime).

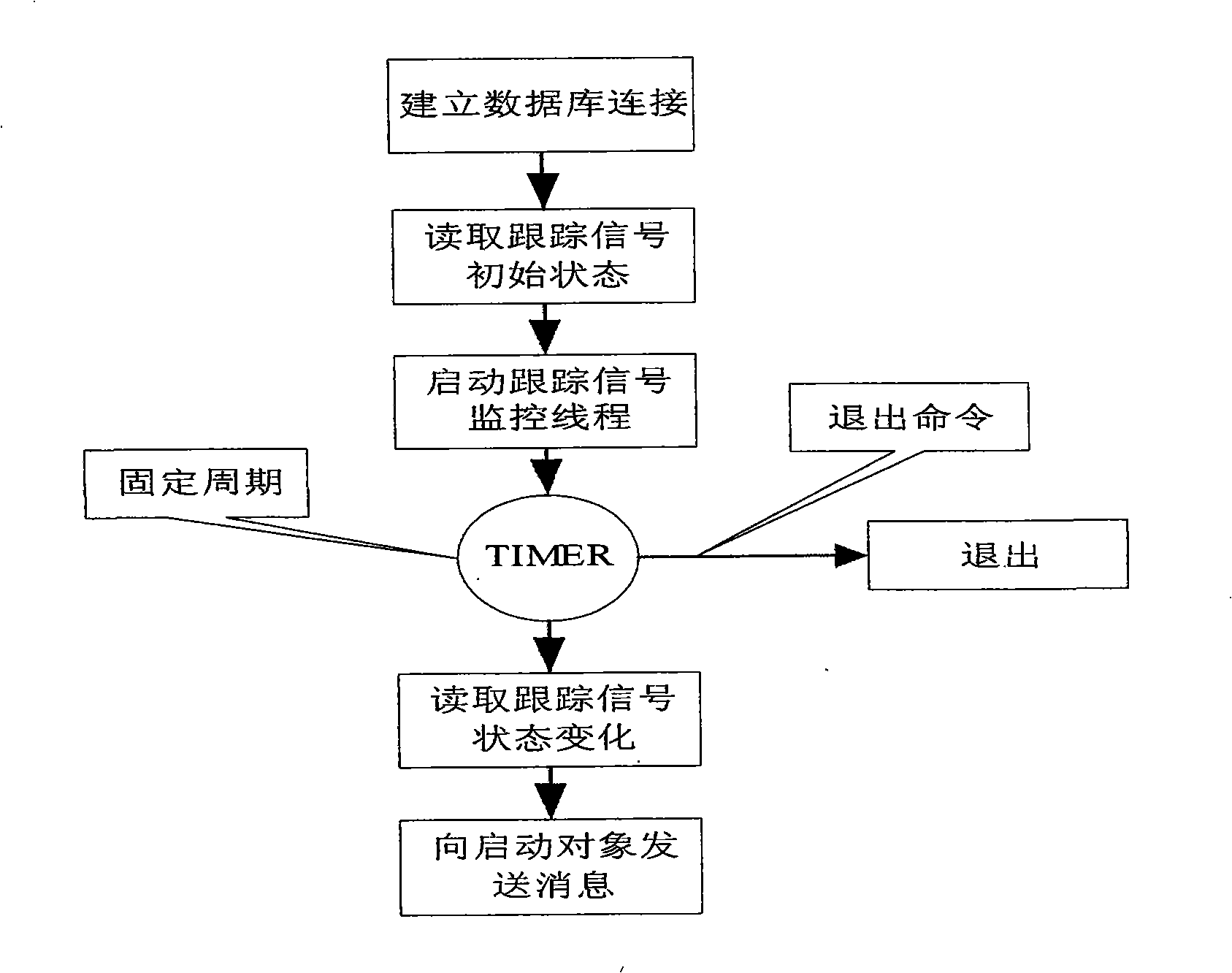

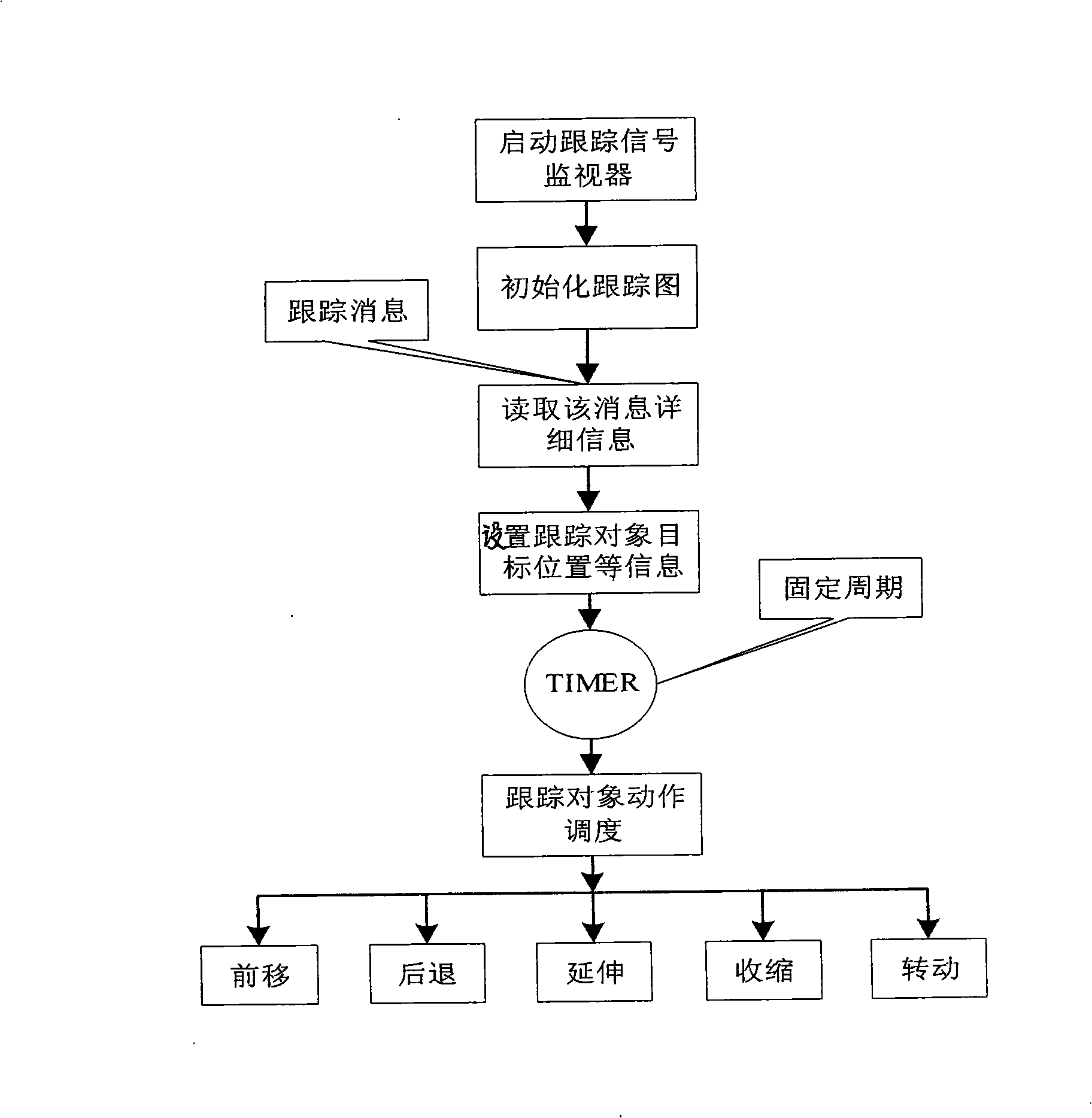

[0017] c. Rolling line signal monitoring and graphic simulation steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com