Industrial internet of things cloud platform interaction system and method for ceramic kiln

An industrial Internet of Things, ceramic kiln technology, applied in the field of cloud platform, can solve problems such as insufficient power, affecting the firing quality of the kiln, and inability to adjust various conditions of the kiln, so as to reduce construction, improve resource utilization and system operation. Reliability, the effect of realizing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

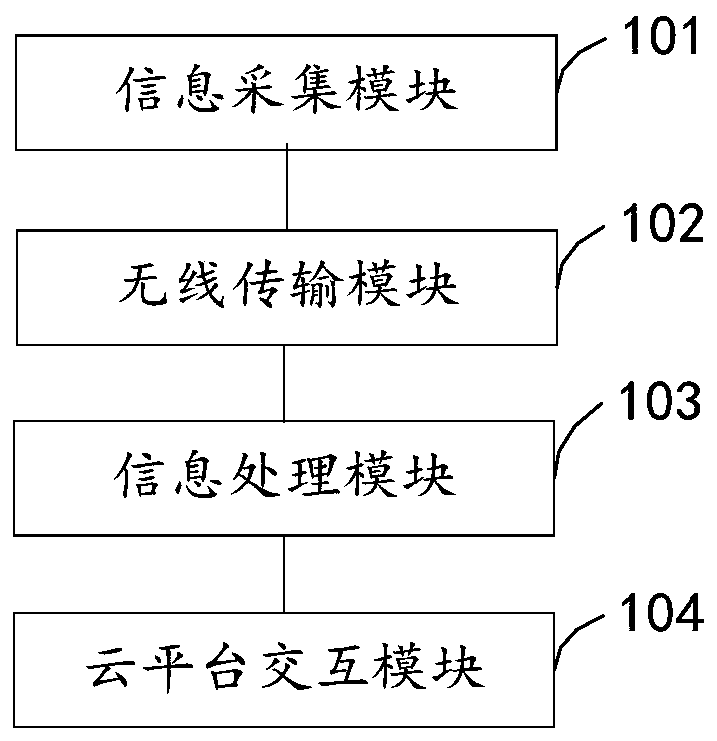

[0033] Such as figure 1 As shown, it is a structural diagram of the interactive system of the industrial Internet of Things cloud platform for ceramic kilns proposed by the present invention.

[0034] refer to figure 1 , an industrial IoT cloud platform interactive system for ceramic kilns, including:

[0035] An information collection module 101, configured to collect images, temperature and exhaust gas information of the kiln;

[0036] The wireless transmission module 102 is used to realize the data communication between the information collection module and the information processing module;

[0037] The information processing module 103 is used to receive and process the information collected by the information collection module, and to report to the police and upload when an abnormality occurs;

[0038] The cloud platform interaction module 104 receives the data information of the information processing module and judges the state of the kiln according to the data info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com