System for achieving intelligent control of transformer cooler group based on double closed loops

A technology of intelligent control and cooler, applied in general control system, control/adjustment system, program control, etc., can solve problems such as slow troubleshooting, inability to start, unfriendly interface operation, etc., to achieve input and removal, precise control The effect of precise discrimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

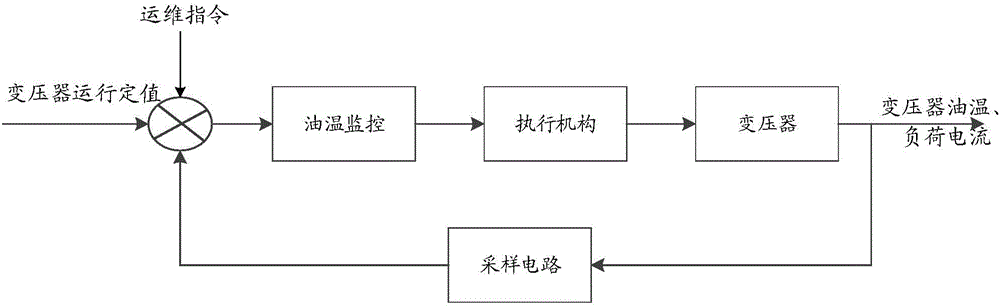

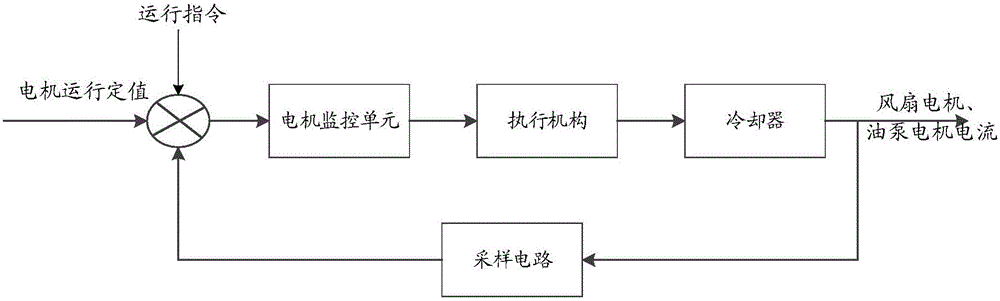

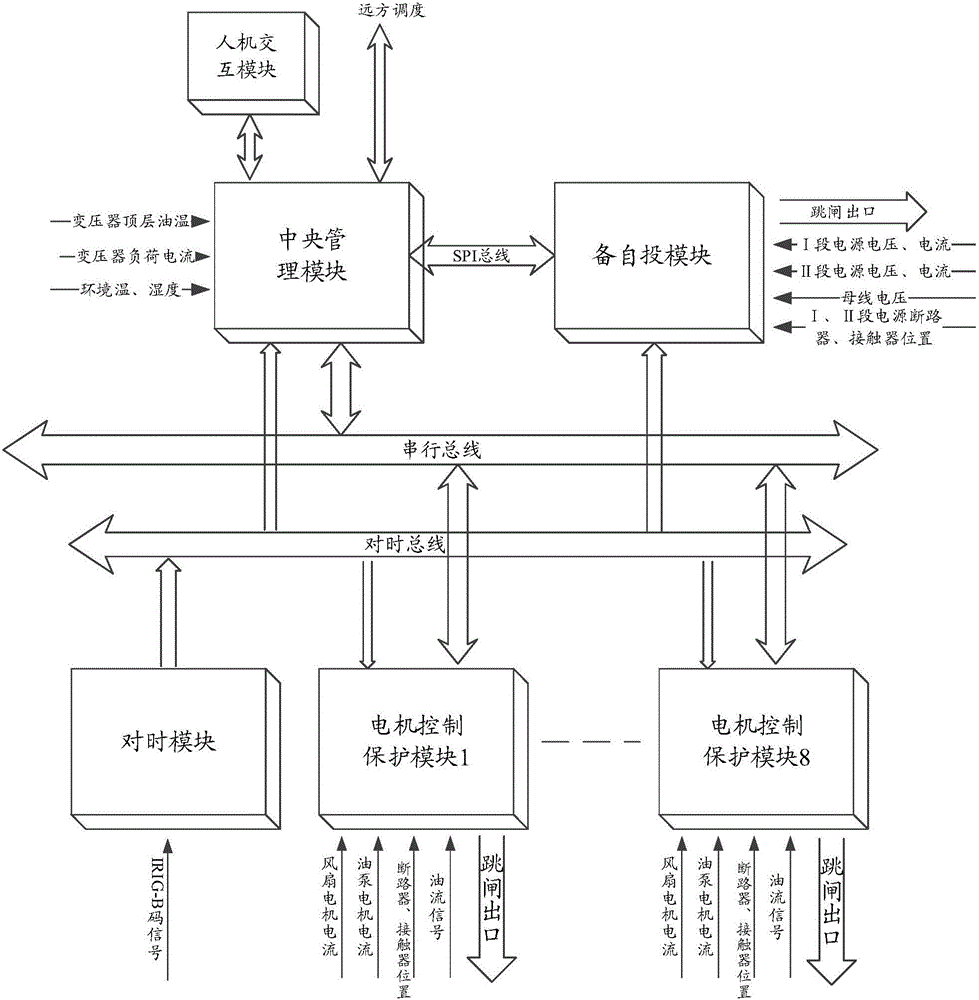

[0034] The system for realizing intelligent control of transformer cooler groups based on double closed-loop loops of the present invention includes a central management module, several motor control and protection modules and transformer data sampling modules, and has double closed-loop control loops. One is a transformer oil temperature control loop (such as figure 1 ), there is an oil temperature monitoring circuit in the central management module of the system. After the system samples the oil temperature of the transformer and the load current signal, it is used as the feedback of the transformer oil temperature adjustment. When the oil temperature exceeds the range of the oil temperature setting value, the central management module adjusts each group Cooler operation to regulate transformer oil tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com