Transformer oil temperature fiber grating monitoring system

A technology of fiber grating and transformer oil, which is applied to thermometers, instruments, thermometers, etc., which are subject to physical/chemical changes, can solve the problems of being susceptible to interference from the surrounding environment and electromagnetic fields, aggravated heat accumulation, and poor heat dissipation effect, and achieves measurement accuracy. And the effect of high effectiveness, simple and clear system operation, easy to expand and upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

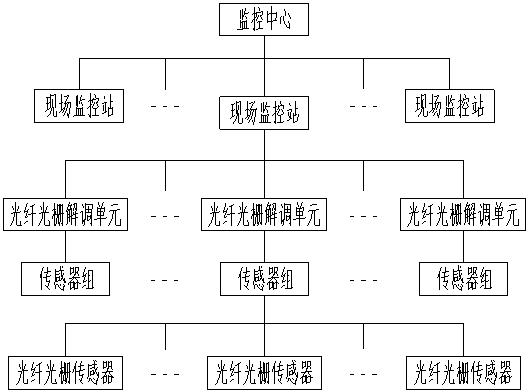

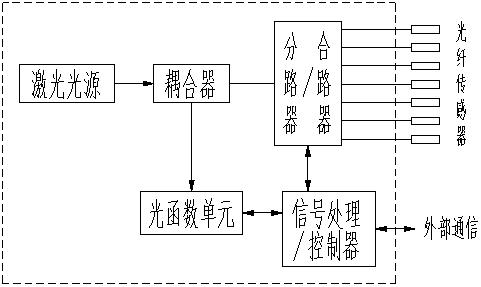

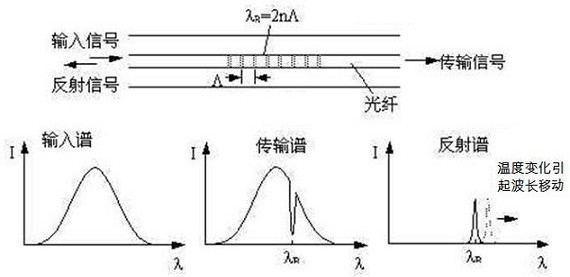

[0018] like Figure 1-3 As shown, the transformer oil temperature fiber optic grating monitoring system includes a fiber optic grating sensor, and the fiber optic grating sensor is arranged in the transformer oil tank and outside the transformer equipment, and is used to collect the temperature inside the transformer equipment oil tank and outside the transformer equipment. Fiber Bragg grating sensors form a sensor group, and the transformer oil temperature fiber Bragg grating monitoring system includes a plurality of sensor groups, and the sensor group is connected to a fiber Bragg grating demodulation unit through an optical fiber, and a plurality of fiber Bragg grating demodulation units are connected to The on-site monitoring station in this area is connected, and the transformer oil temperature fiber grating monitoring system includes a plurality of on-site monitoring stations, and a plurality of on-site monitoring stations are connected to the monitoring center through op...

Embodiment 2

[0021] like Figure 1-3 As shown, the transformer oil temperature fiber optic grating monitoring system includes a fiber optic grating sensor, and the fiber optic grating sensor is arranged in the transformer oil tank and outside the transformer equipment, and is used to collect the temperature inside the transformer equipment oil tank and outside the transformer equipment. Fiber Bragg grating sensors form a sensor group, and the transformer oil temperature fiber Bragg grating monitoring system includes a plurality of sensor groups, and the sensor group is connected to a fiber Bragg grating demodulation unit through an optical fiber, and a plurality of fiber Bragg grating demodulation units are connected to The on-site monitoring station in this area is connected, and the transformer oil temperature fiber grating monitoring system includes a plurality of on-site monitoring stations, and a plurality of on-site monitoring stations are connected to the monitoring center through op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com