Intelligent management system for production line

An intelligent management system and production line technology, applied in the general control system, control/adjustment system, comprehensive factory control, etc., can solve problems such as low production efficiency, confusion in the appointment of operators, poor product quality control, etc., to improve production quality, avoid confusing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

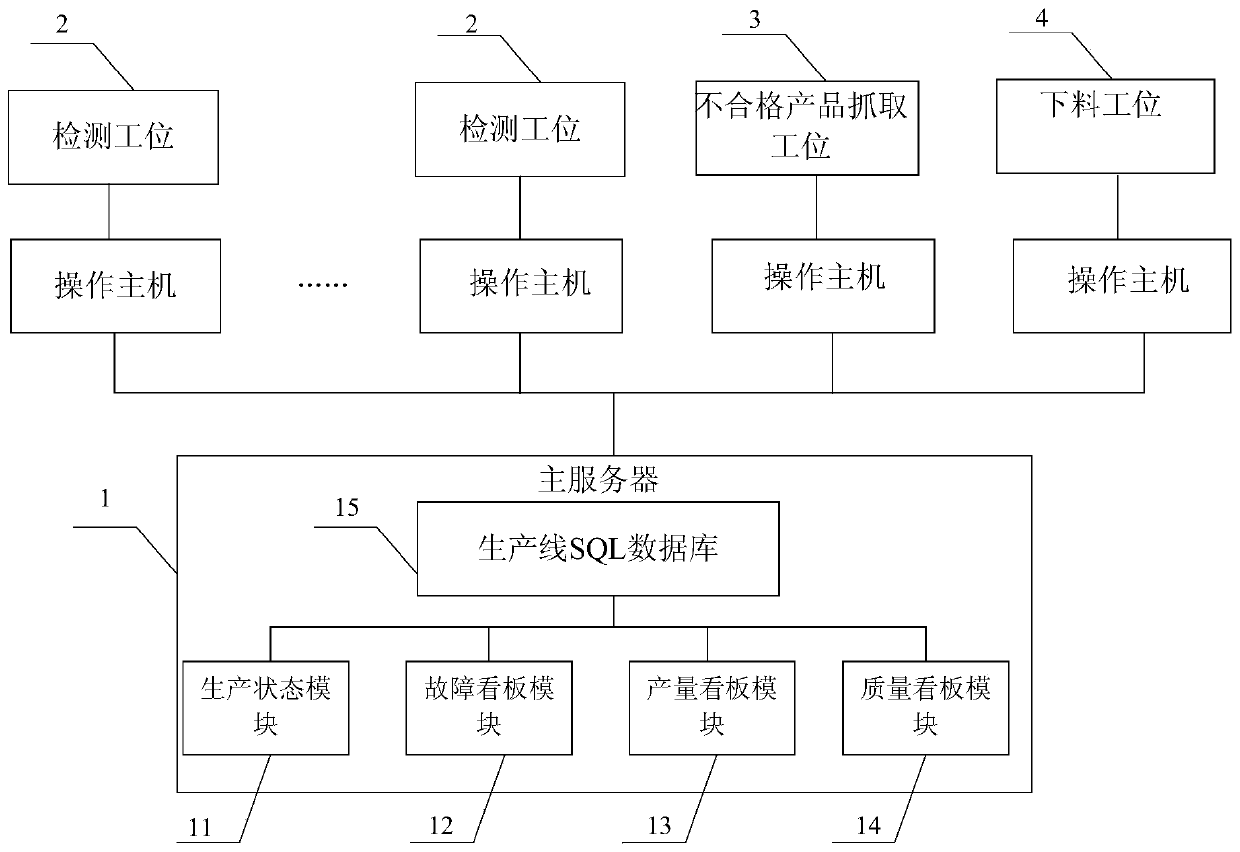

[0032] Specific implementation mode one: the following combination figure 1 Describe this embodiment, a production line intelligent management system described in this embodiment, the system includes a main server 1 and an operation host installed at each station of the production line and connected;

[0033] The main server 1 is connected to the operating host installed at each station of the production line to form a local area network through a network cable;

[0034] The production line includes N detection stations, grabbing stations for unqualified products and a blanking station, and the blanking station is the last station of the production line;

[0035] The N detection stations, unqualified product grabbing stations, and unloading stations all use the method of scanning QR codes to identify products; Send to master server 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com