Preparation method for fine denier polyester industrial yarn

A manufacturing method and technology of fine denier polyester, applied in melt spinning, filament forming treatment, textile and paper making, etc., to achieve stable quality, low production cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

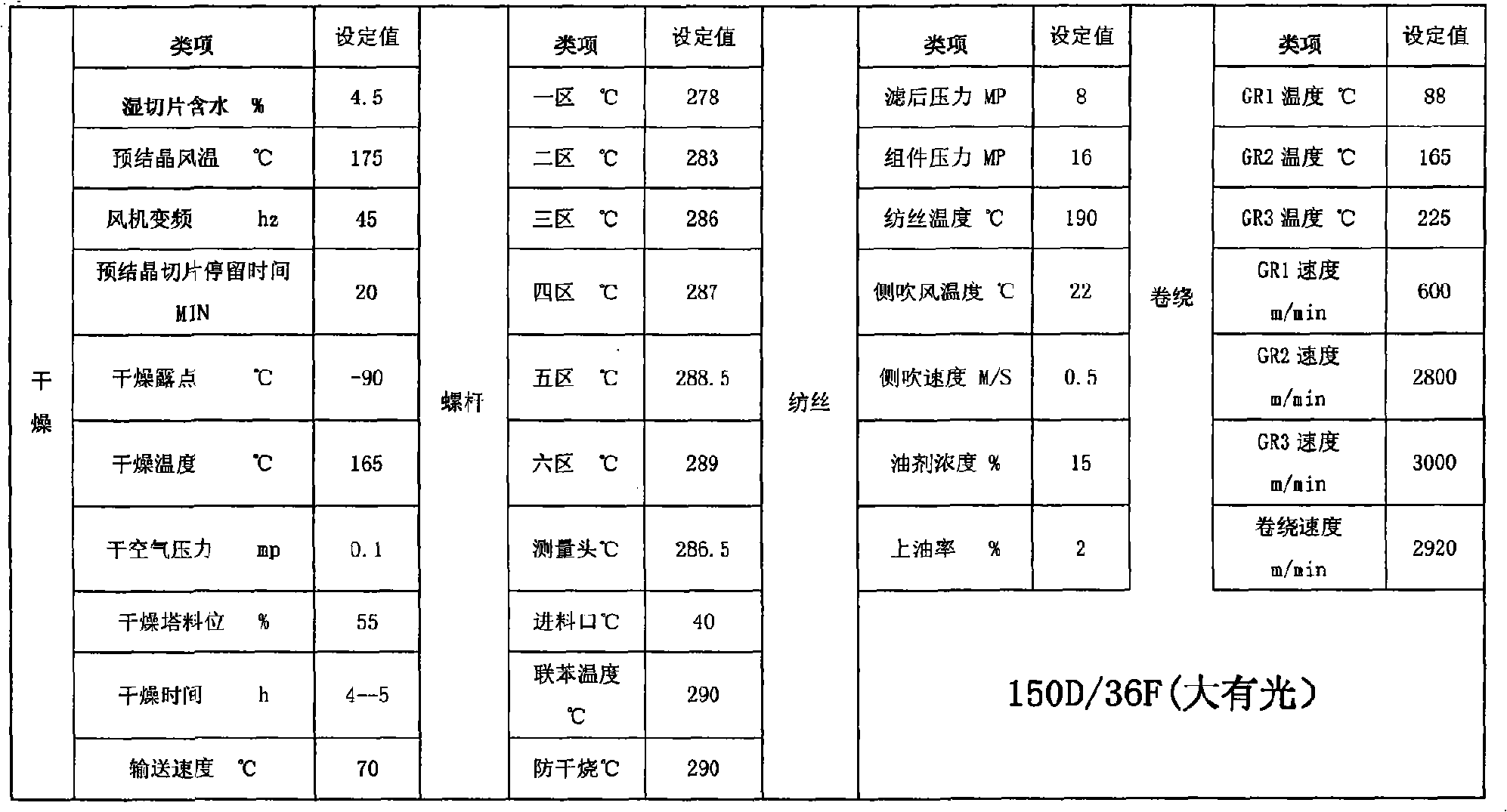

[0016] The following is a specific embodiment of the present invention: producing polyester sewing thread 150D / 36f (big bright)

[0017] The production process is as follows: polyester high-viscosity chip (Dayouguang) intrinsic viscosity IV=0.75dl / g. The slices are pre-crystallized at 175°C for about 20 minutes, and sent to a drying tower for 6-8 hours at a drying temperature of 165°C. Ensure that the moisture content of the slices is less than 30ppm, and control the viscosity down to 2%. The dried chips are melted, mixed, metered, and filtered into the spinning box for spinning through a screw extruder. The melt passes through a circular spinneret hole (0.32mm in the hole diameter) and a 36-hole circular spinneret. , after cooling by side blowing, oiling, drawing, and winding to obtain polyester sewing thread, and then go through hosiery knitting, color judgment, external inspection, and grading packaging.

[0018] Process parameter in the above-mentioned procedure is:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com