High-accuracy mold design method and mold manufacturing management system

A mold design and management system technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve problems such as technology can not be perfected, achieve personalized needs, improve mold quality, and meet various needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

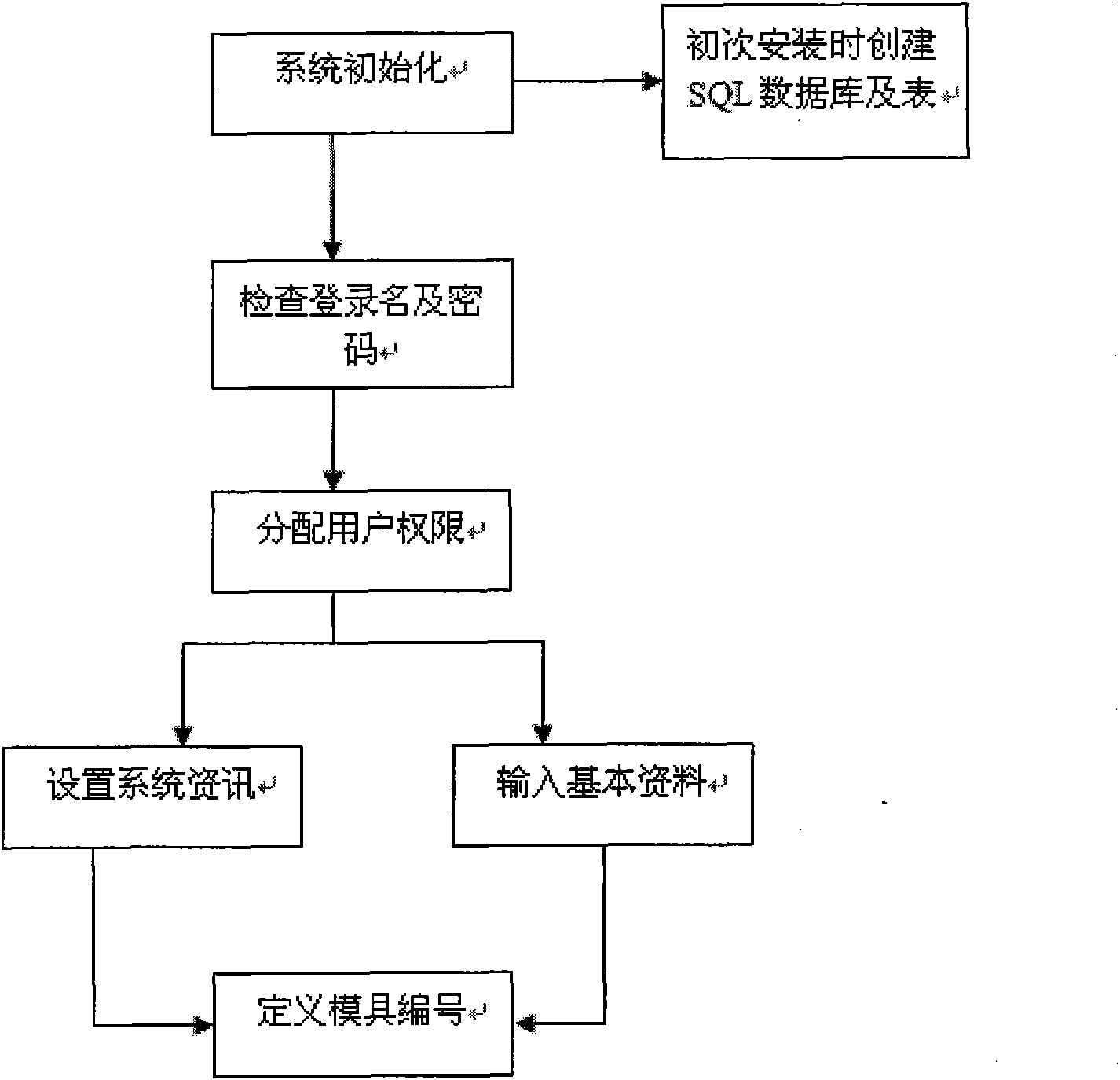

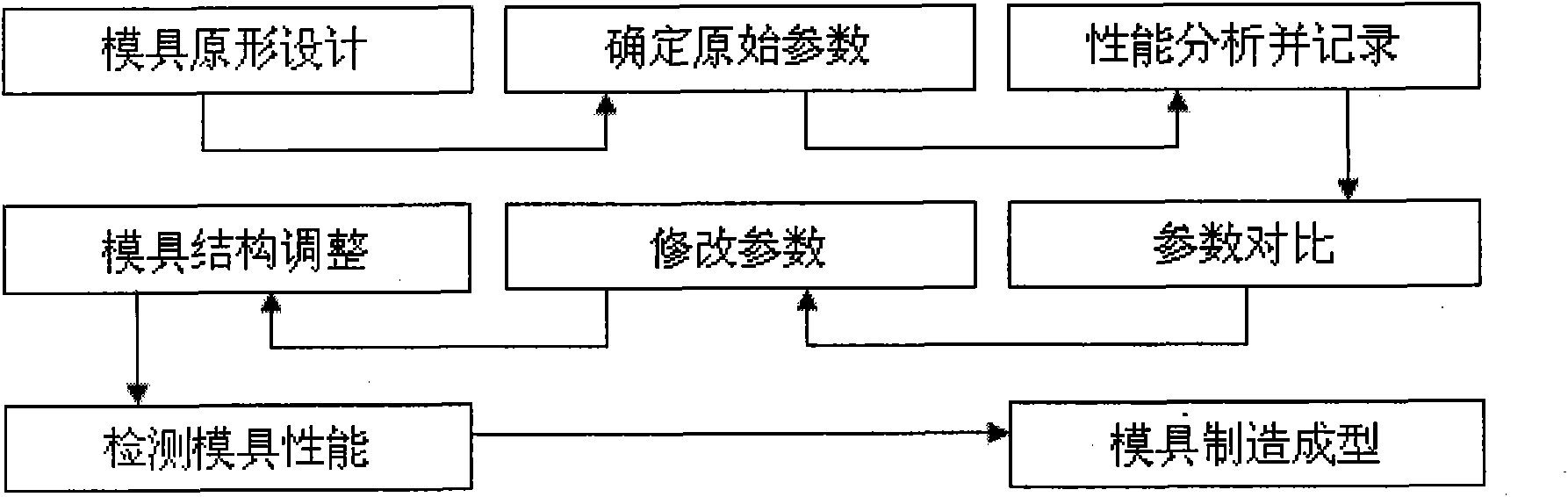

[0023] see figure 1 and image 3 , a high-precision mold design method, the method includes the following steps:

[0024] (1) Set up computer-aided design tools to comprehensively process mold precision parameters with mold design integrated mold optimization tools;

[0025] (2) Mold design: make the prototype of the mold structure by the computer-aided design tool, and determine the original performance parameters of the designed mold;

[0026] (3) Mold precision analysis: use mold design software to analyze the comprehensive performance of the designed mold, and record the data value;

[0027] (4) Mold precision optimization: compare the original performance parameters of the mold and use mold optimization tools to modify the unreasonable structure and substandard performance parameters of the mold; determine the mold structure after testing.

[0028] The step (1) also includes the following steps: the mold design integrated mold optimization tool adopts the integrated us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com