Printing apparatus and processes employing intermediate transfer with molten intermediate transfer materials

a technology of intermediate transfer and printing apparatus, which is applied in the direction of electrographic process apparatus, printing, instruments, etc., can solve the problems of inability to allow oil to pass through the maintenance cartridge and affecting the quality of the intermediate transfer member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

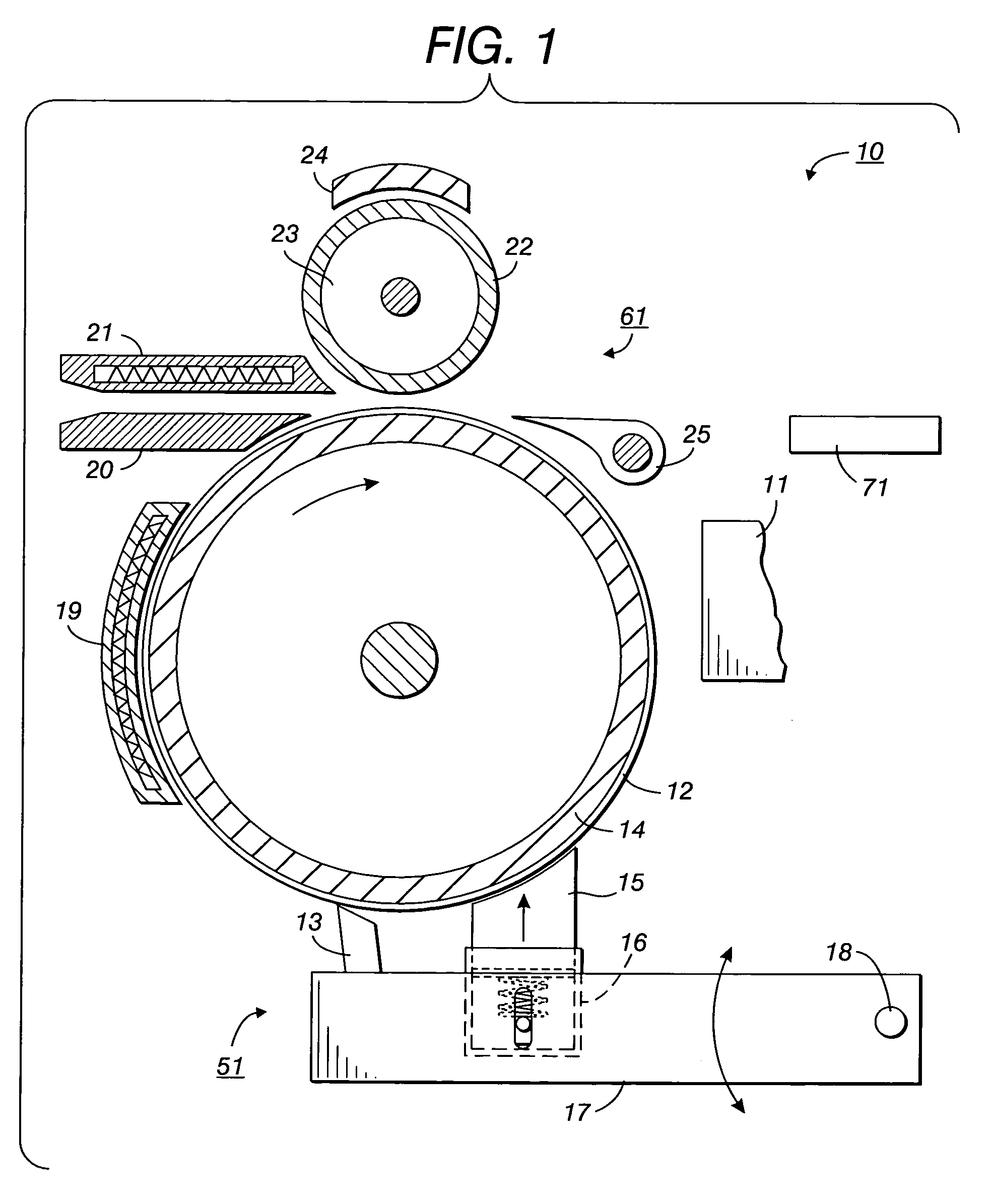

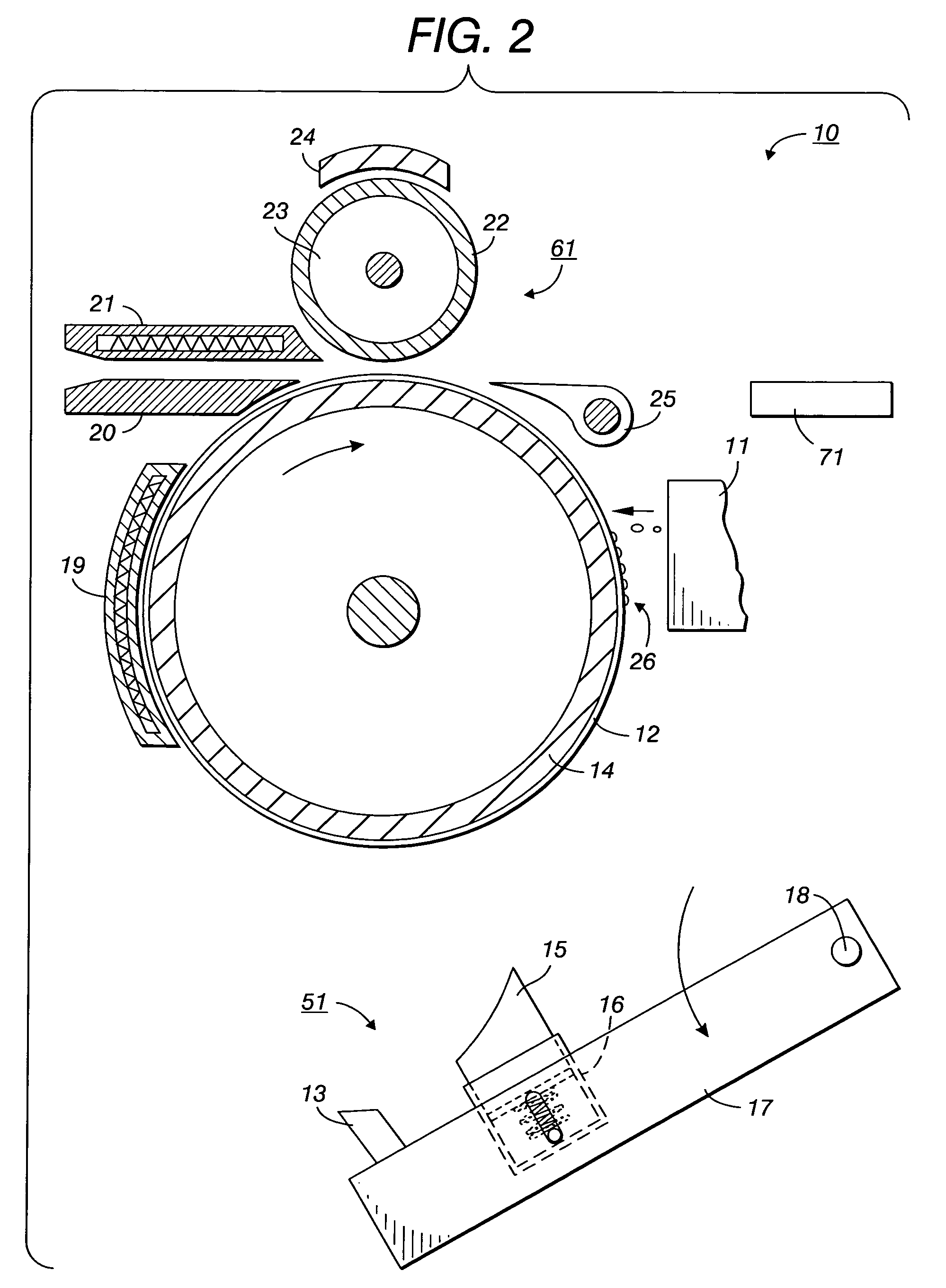

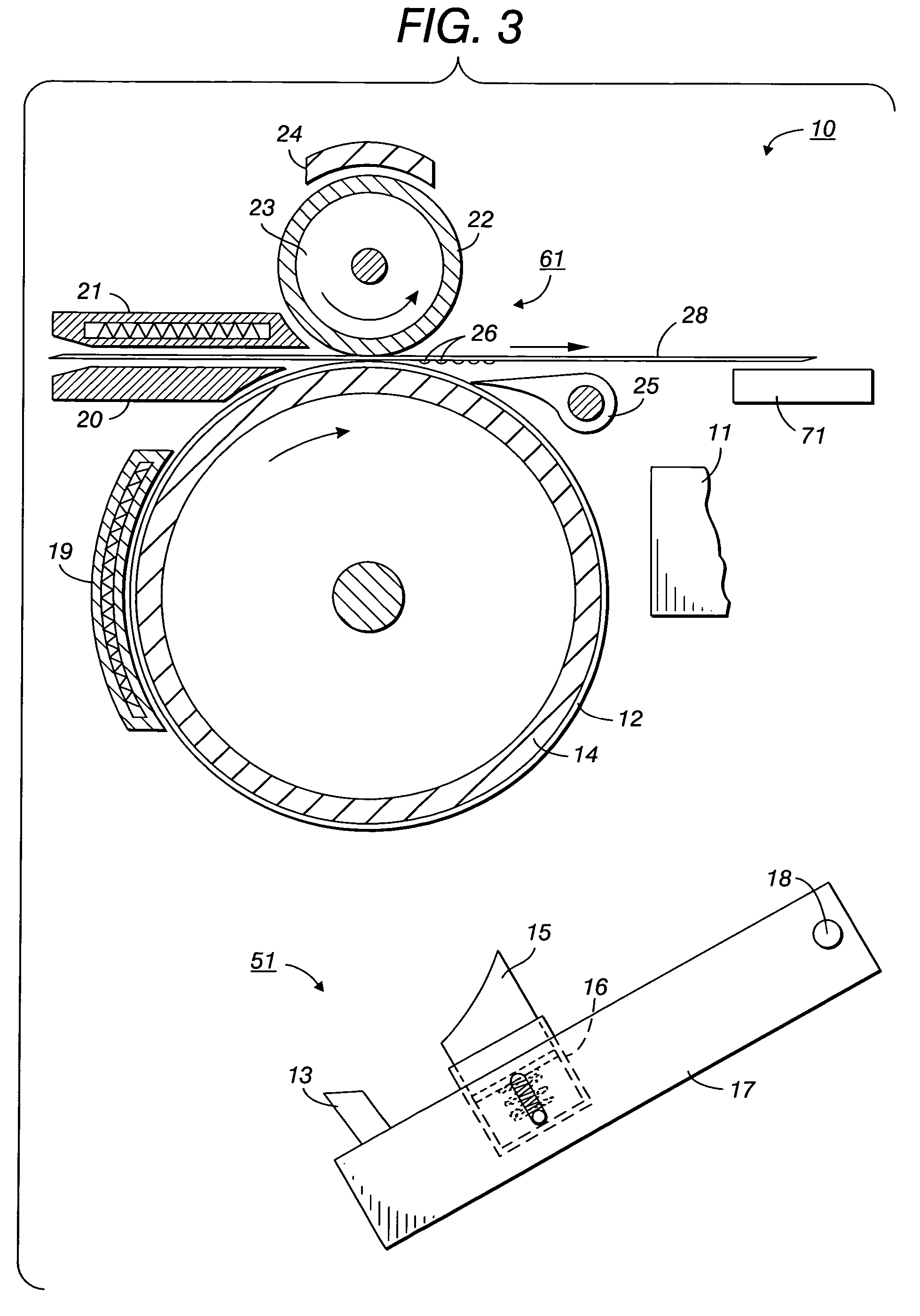

Image

Examples

example i

To a 4-neck, round bottom flask equipped with a stirrer, condenser, temperature controller, and sparge tube are charged 200 grams of 1-octadecene (available from CPChem Company, The Woodlands, Tex.), 100 grams of toluene, and 52.8 grams of polymethylhydrosilane HMS-991 (available from Gelest, Inc., Tullytown, Pa.) of the following formula:

(n=22-30, MW=1,500-1,900 g / mol). The flask contents are agitated and heated to 100° C. The reaction mixture is sparged with a light stream of nitrogen gas. After equilibrating at the mentioned temperature, heating and sparging are discontinued, and the reaction is catalyzed with 0.3 cc of 3.3% chloroplatinic acid solution in ethanol. Subsequently, the temperature of the reaction mixture goes to a maximum of 110° C. within 10 minutes. After the reaction goes to completion, the mixture is treated with 2% water and 0.2% concentrated HCl at a temperature of approximately 60° C. for one hour. Afterwards, the reaction mixture is neutralized with dry ...

example ii

To a 4-neck, round bottom flask equipped with a stirrer, condenser, temperature controller, and sparge tube are charged 200 grams of allyl alcohol propoxylate (available from Aldrich Chemical Co., Milwaukee, Wis., Cat. Number 43,037-4), of the formula

wherein x represents the number of repeat propoxylate groups (average value of from about 1.4 to about 1.8; average number average molecular weight 140-160), 90 grams of toluene, and 283.8 grams of methylhydrosiloxane dimethylsiloxane Copolymer HMS-301 (available from Gelest, Inc., Tullytown, Pa.) of the following formula:

(m=7-9, n=17-19, MW=1,900-2,000 g / mol). The flask contents are agitated and heated to 95° C. with a light nitrogen sparge. After equilibrating at this temperature, heating and sparging are discontinued, and the reaction is catalyzed with 0.3 cc of 3.3% chloroplatinic acid solution in ethanol. Subsequently, the temperature of the reaction mixture goes to a maximum of 110° C. within 10 minutes. After the reaction ...

example iii

To a 4-neck, round bottom flask equipped with a stirrer, condenser, temperature controller, and sparge tube are charged 300 grams of the product prepared in Example II and 310 grams of stearyl isocyanate (available as Mondur O from Bayer Corp., Pittsburgh, Pa.). The mixture is melted in the flask, brought to a temperature of 120° C., and stirred. After thermal equilibrium has been reached, 2 drops of a catalyst solution (dibutyltin oxide, FASCAT® 4202, available from Atofina Chemicals, Philadelphia, Pa.) are added. The reaction becomes exothermic, and the temperature peaks at 150° C. Subsequently, the reaction mixture is stirred for another 1.5 hours. FTIR analysis can be used to determine that all of the isocyanate has reacted with the alcohol groups of the dimethicone copolyol from Example II. It is believed that the product obtained will have the formula

wherein m=7-9, n=17-19, and x has an average value of from about 1.4 to about 1.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com