Strip material applicator of case sealer

A technology of applicator and fixed unit, applied in the field of material applicator, can solve the problem of time-consuming and achieve the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

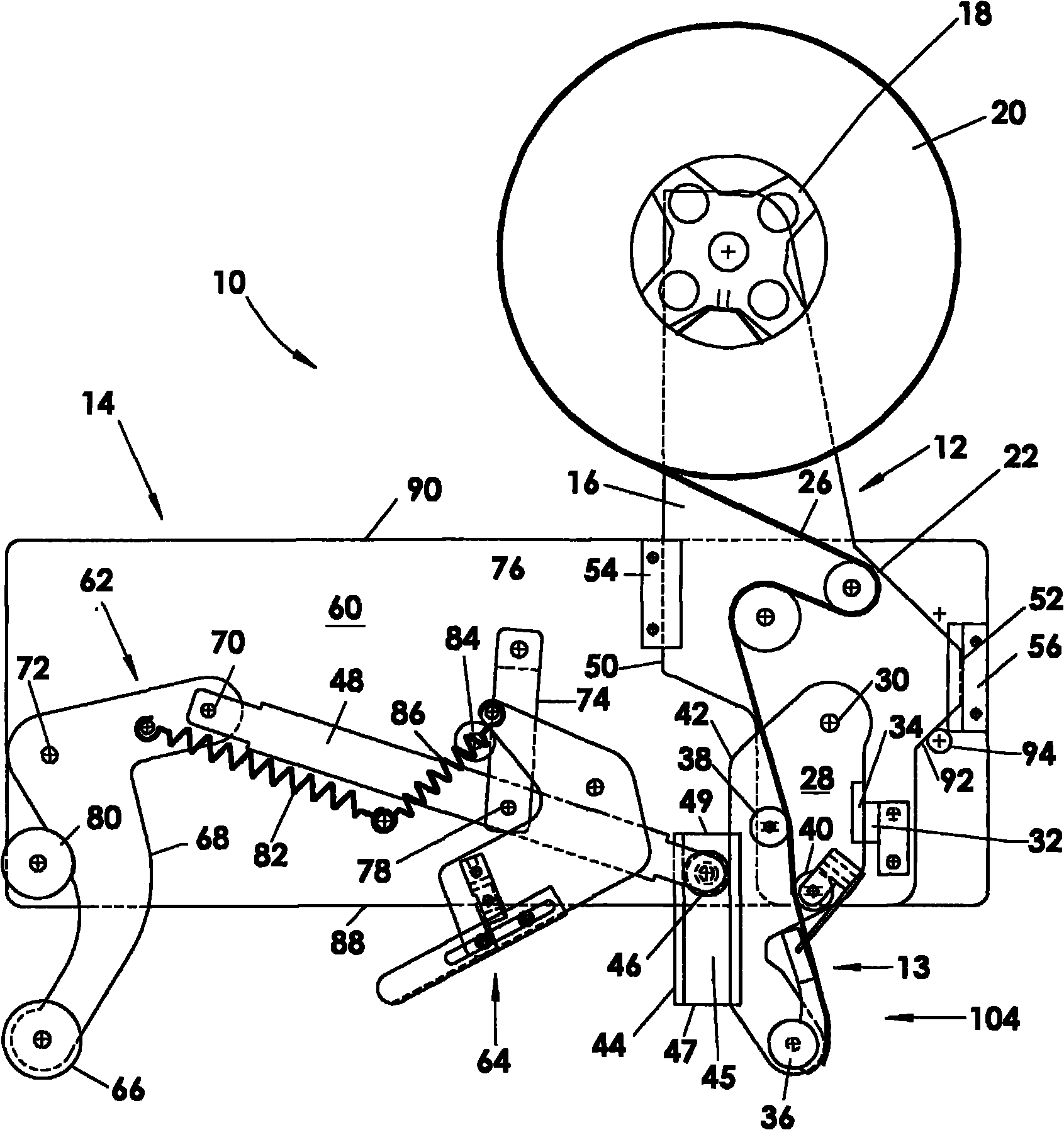

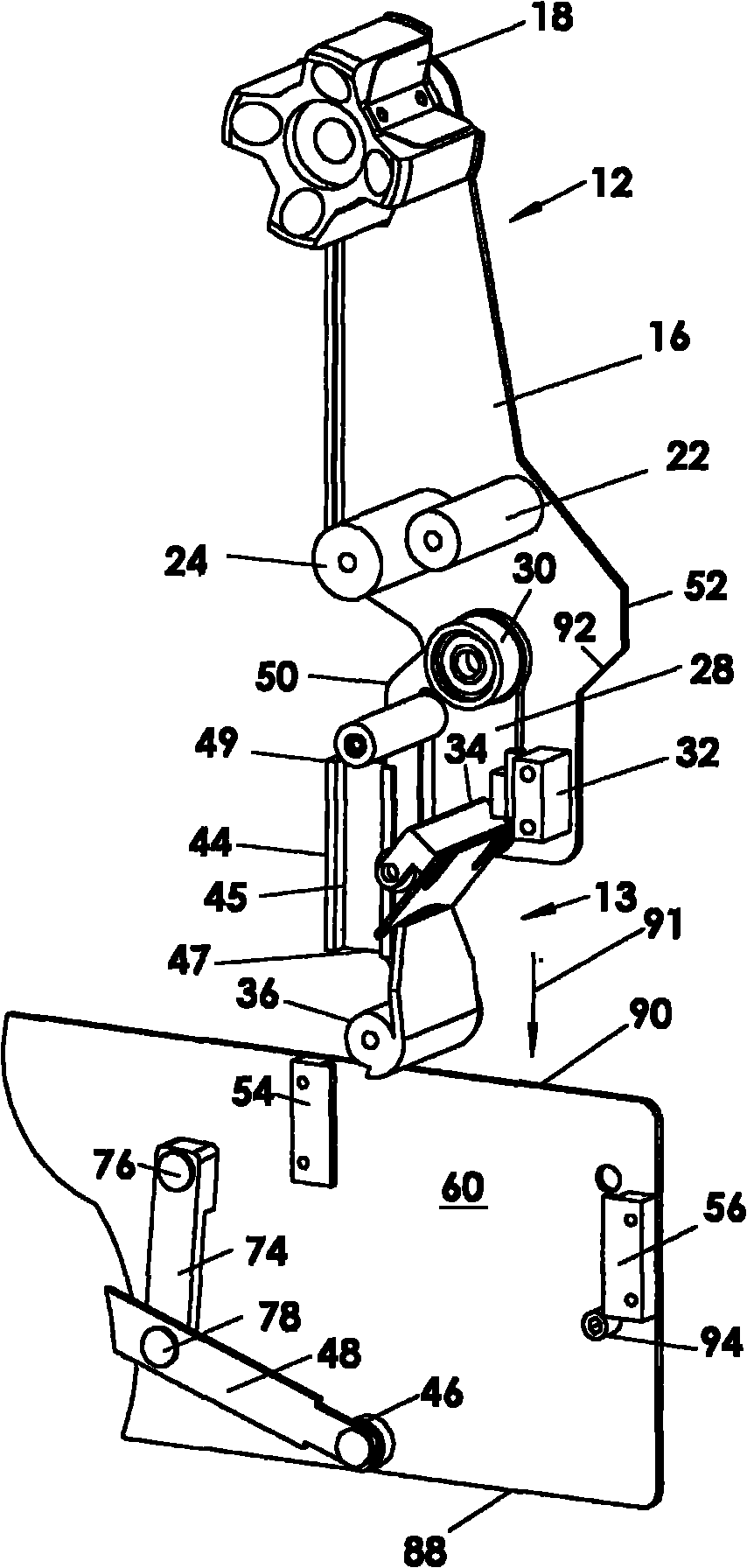

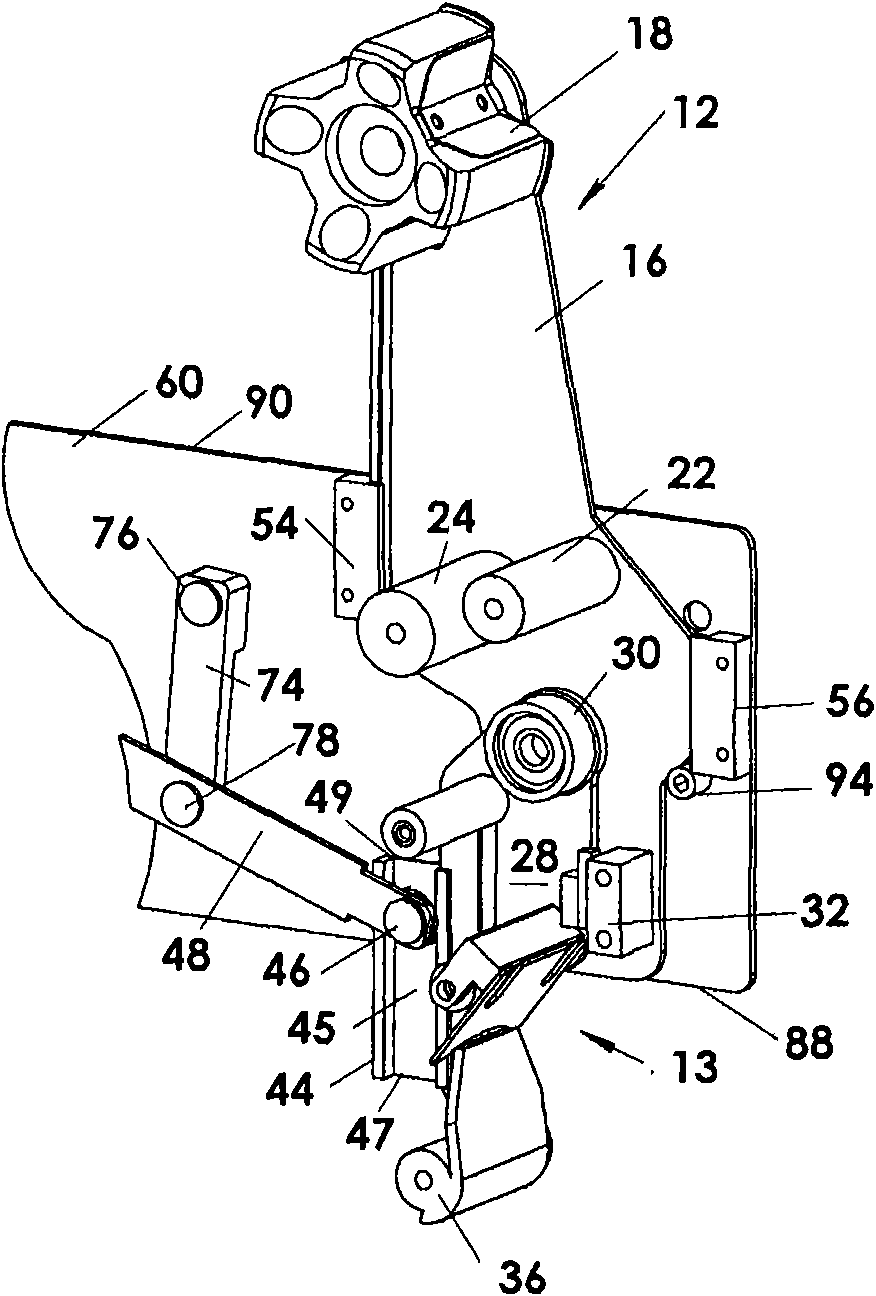

[0025] As shown in the drawings, the tape applicator 10 of the present invention consists of two parts, a detachable unit 12 that is removably mounted in a fixed unit 14, and a removable unit 12 that is fixed to use the tape applicator (see Figures 1 to 5 , Figures 1 to 3 Show Top Tape Applicator, Figure 4 with 5 The fixing unit 14 on the machine (not shown) of the bottom tape applicator is shown.

[0026] The removable unit 12 is formed by an auxiliary frame 16 on which is mounted the front part 13 of the tape applicator mechanism. The front portion 13 ("front" because it is used to apply the tape to the front end 102 of the case 100 as the tape moves past the tape applicator 10) includes a belt for mounting the tape. A tape reel stand 18 for a roll 20 and, if desired, tape guide rollers 22 and 24 around which the tape 26 passes. A front link 28 is pivotally mounted to the subframe 16 on an axle 30 and forms part of the front section 13 . Front link 28 is releasably h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com