Automobile engine assembly transfer case

An automobile engine and turnover box technology, which is applied in the direction of assembling machines, assembling vehicles, machine containers, etc., can solve the problems of large differences in the size and quality of the engine assembly, inconvenient use and management of troops, and affecting the versatility of the turnover box. , to achieve the effect of high strength and rigidity, universality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

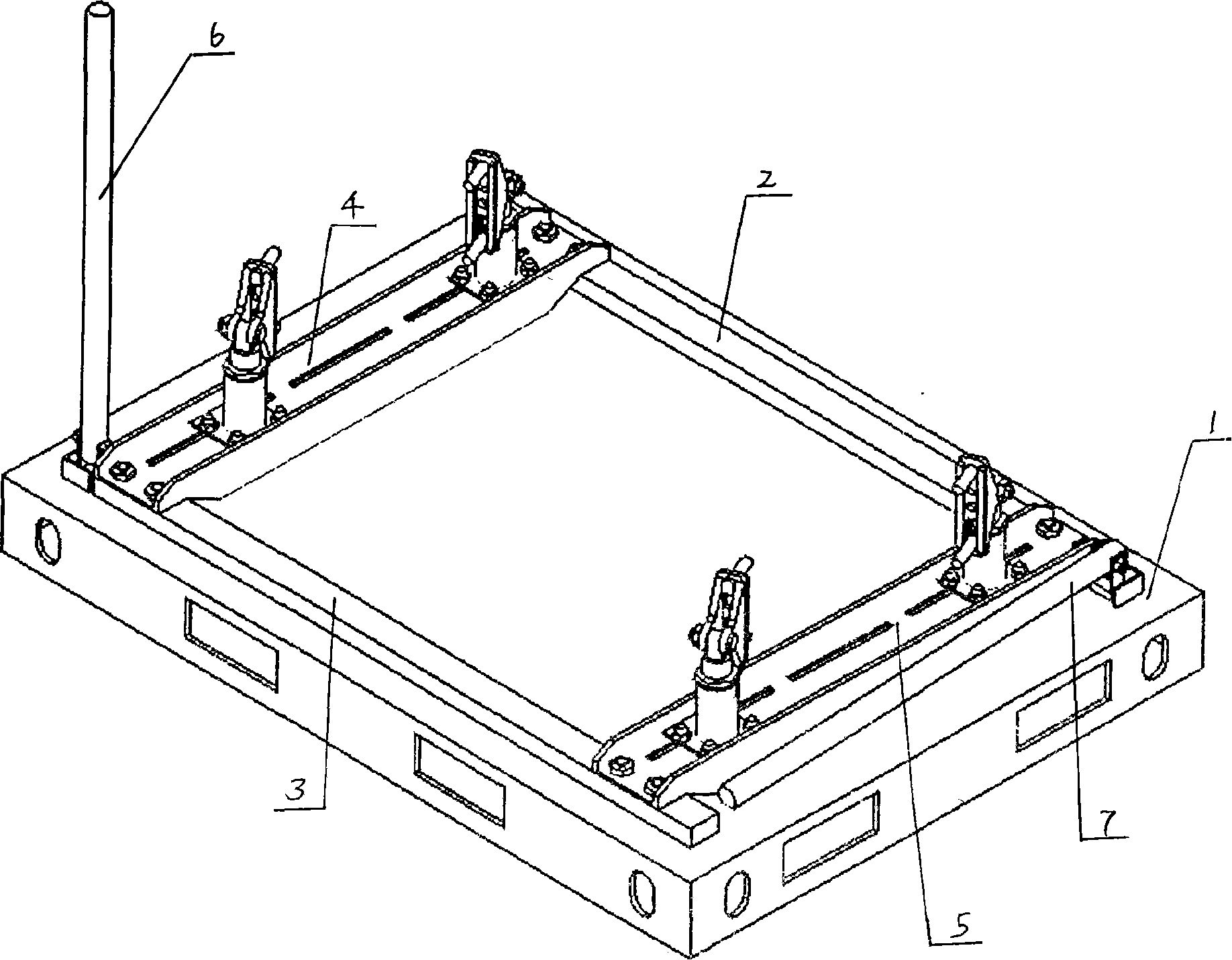

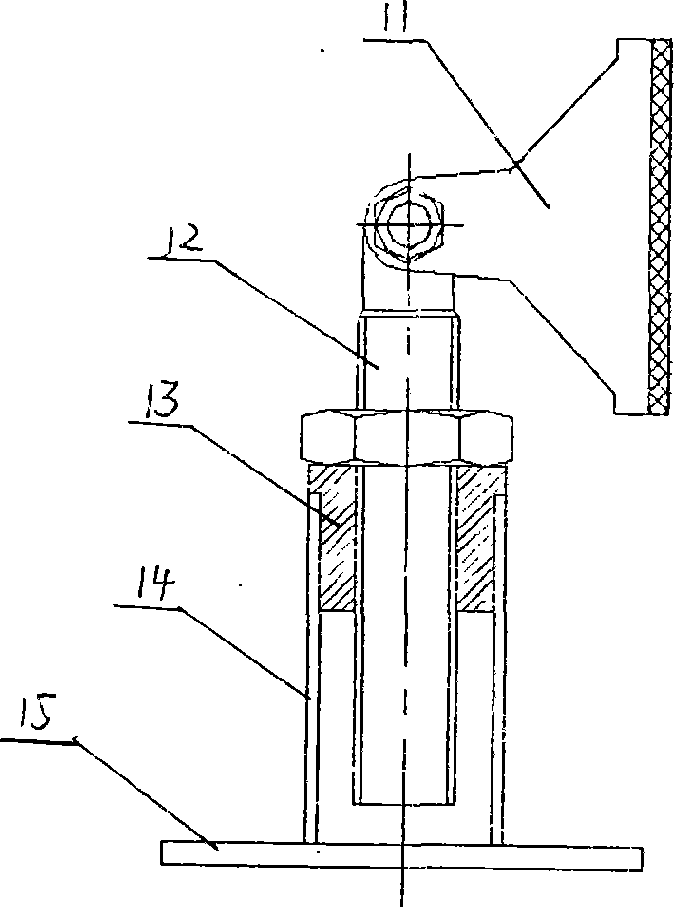

[0033] The present invention includes tray assembly, support head assembly, case cover; figure 1 As shown, the pallet assembly is composed of a pallet, a slide rail, and a hasp. The pallet 1 is provided with two parallel fixed slide rails 2 and 3, and the two ends of the two moving slide rails 4 and 5 are respectively arranged on two fixed slide rails. In the tracks of rails 2 and 3, two guide rods 6 and 7 are arranged at the opposite corners of the tray. Two buckles are arranged on the front and back sides of the tray; the box cover is connected with the tray through the buckles. Such as figure 2As shown, the support head assembly includes a fixed seat 11, a stud 12, a screw sleeve 13, a steel pipe 14 and a base 15, the fixed seat 11 and the stud 12 are connected by a pin shaft, and the left and right sides of the pressure bearing surface of the fixed seat are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com