Step type rice potted seedling transplanter

A technology of transplanting machine and pot seedlings, which is applied in the field of step-pitch rice pot seedling transplanting machines, can solve the problems of low production efficiency, messy pot seedlings, and high requirements for seedling raising, so as to reduce the requirements of seedling raising technology and improve mechanization level, the effect of increasing grain production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

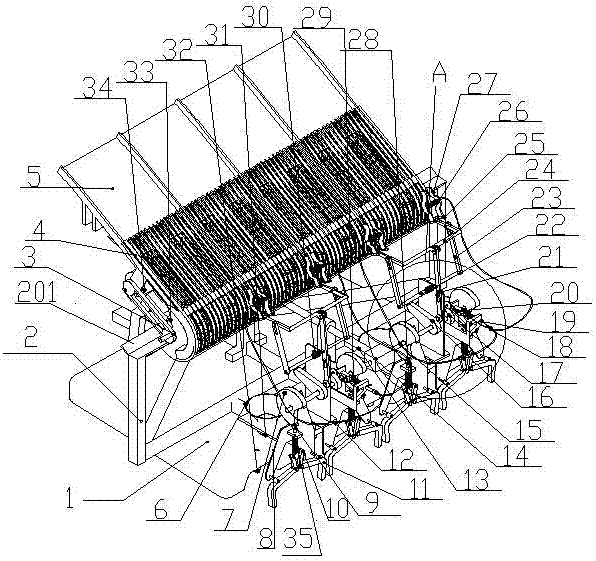

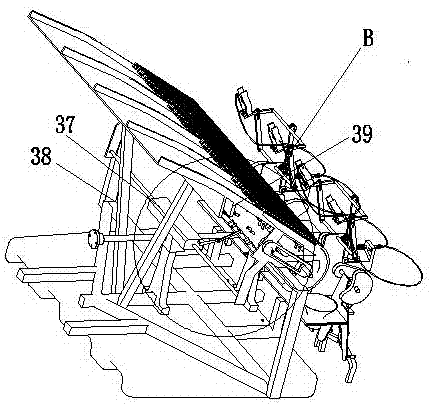

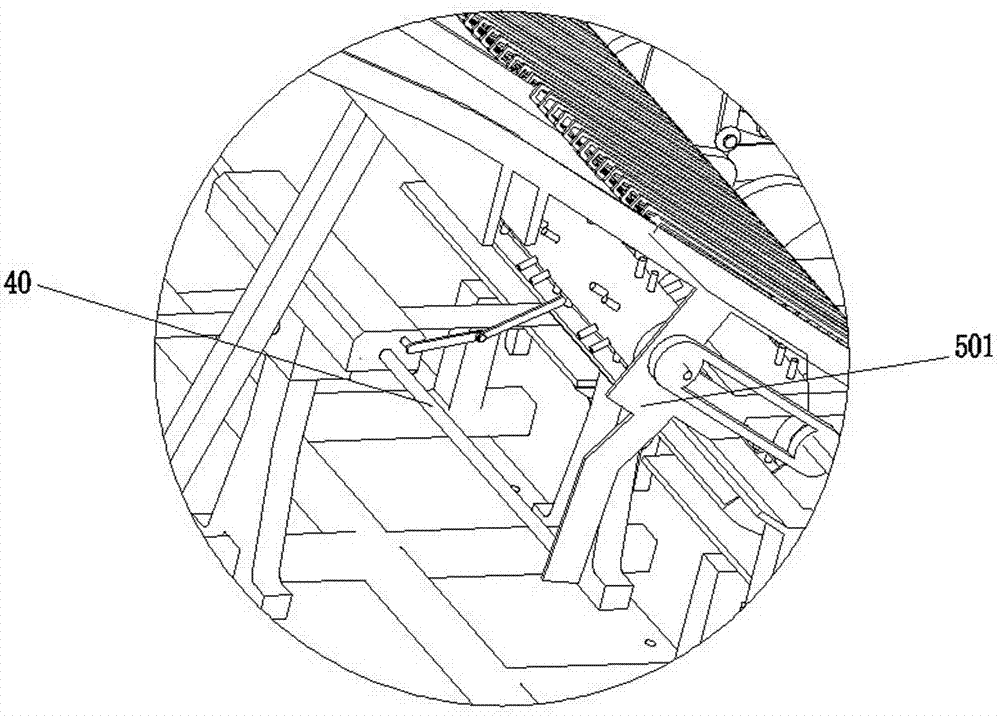

[0034] see Figure 1 to Figure 7 A step-pitch type rice pot seedling transplanting machine, including fuselage connecting fixed frame 2, ditching and ridging device, pot seedling conveying device, several sets of pot seedling taking devices, seedling transporting funnel 6, several sets of pot seedling righting devices and power input device; wherein, the ditching and ridge device is located at the bottom of the fuselage connection fixed frame 2, and the pot seedling conveying device is slidably installed on the chute guide rail 201 of the fuselage connection fixed frame 2, and several sets of pot seedling device Seedling fetching claws 27 are arranged side by side at the outlet end of the pot seedling conveying device, and each set of pot seedli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com