A fig tree seedling cultivation machine and its soil collecting component

A technology of fig trees and cultivation machines, which is applied in agriculture, forestry, application, etc. It can solve the problems of inability to guarantee the growth shape of seedlings, low work efficiency, and low precision of quantity control, so as to improve the efficiency of seedling transplanting and reduce labor costs. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

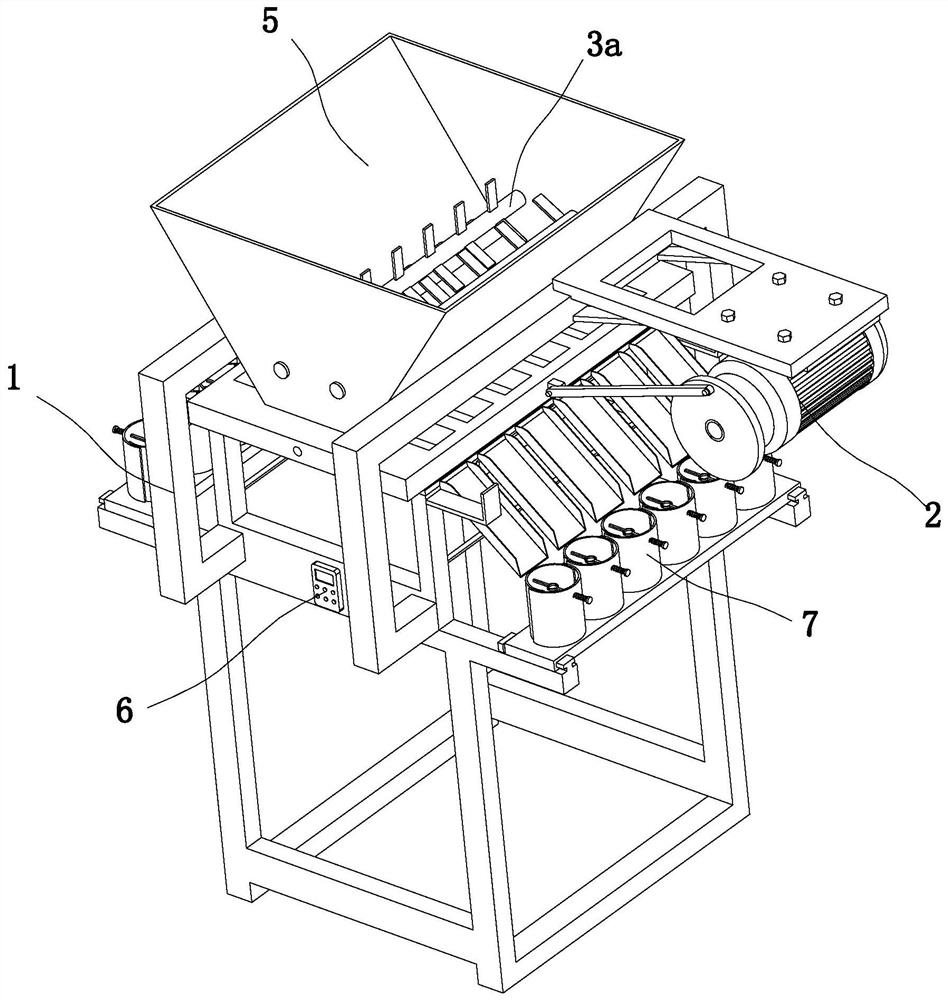

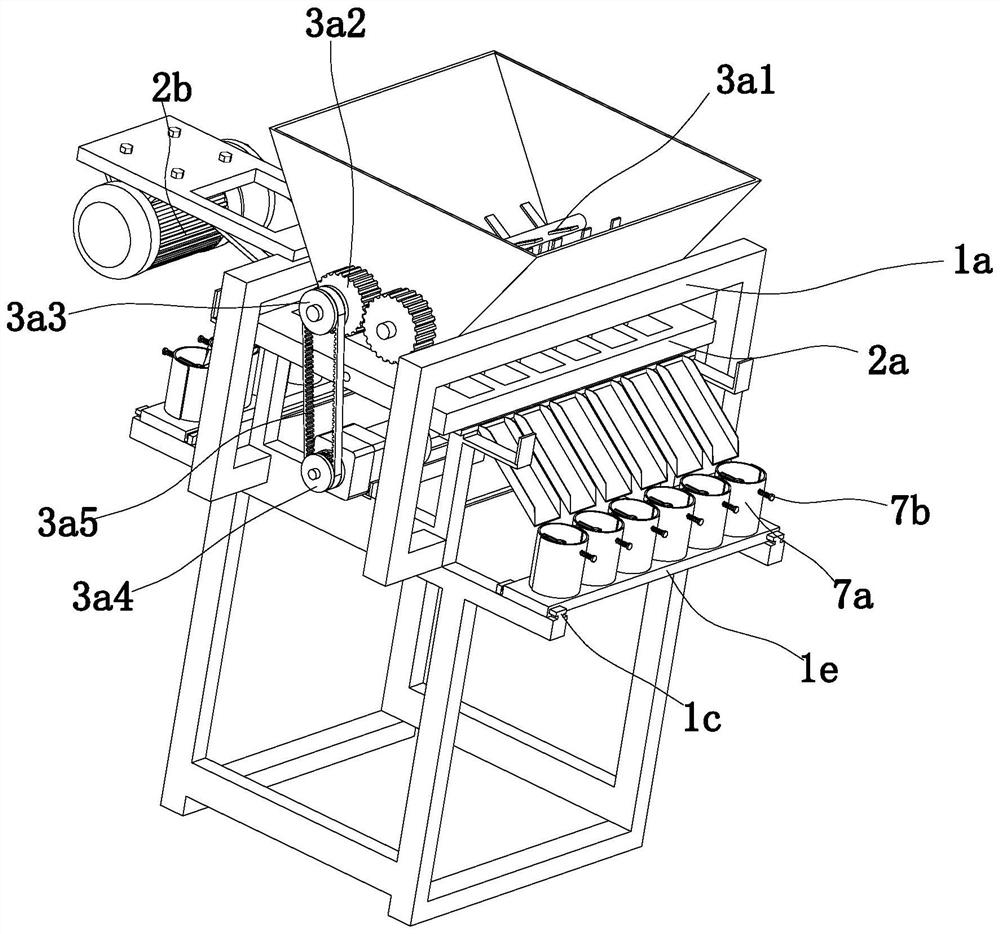

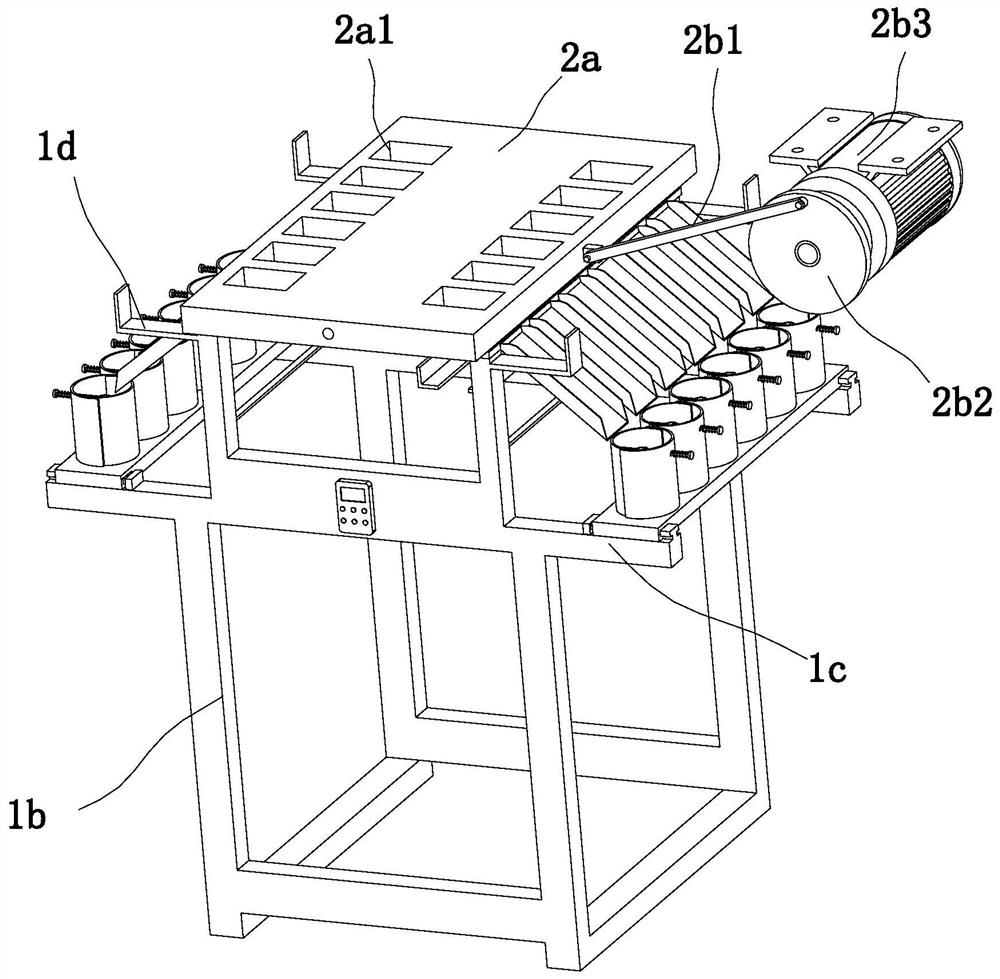

[0030] The present invention provides a kind of fig tree seedling cultivator here by improving, as Figure 1-Figure 4 Shown, a kind of fig tree seedling cultivating machine comprises organic frame 1, and described frame 1 is made up of upper frame 1a and lower frame 1b, and described seedling cultivating machine also includes delivery device 2, stirring device and control Panel 6, several supporting ears 1c extend horizontally from the upper part of the lower frame 1b, a supporting plate 1e is placed on the supporting ears 1c on the side of the frame 1, and a baffle plate is horizontally arranged on the top of the lower frame 1b 1f, the edge of the baffle 1f is provided with several guide plates 4 obliquely downwards, and the conveying device 2 includes a push plate 2a that is horizontally attached to the upper surface of the baffle 1f and can drive the push plate 2a on the baffle. 1f is a linkage assembly 2b that moves back and forth horizontally and linearly. The top of the ...

specific Embodiment 2

[0038] refer to Figure 1 to Figure 2 Shown, a kind of fig tree seedling cultivating machine comprises organic frame 1, and described frame 1 is made up of upper frame 1a and lower frame 1b, and described seedling cultivating machine also includes delivery device 2, stirring device and control Panel 6, several supporting ears 1c extend horizontally from the upper part of the lower frame 1b, a supporting plate 1e is placed on the supporting ears 1c on the side of the frame 1, and a baffle plate is horizontally arranged on the top of the lower frame 1b 1f, the edge of the baffle 1f is provided with several guide plates 4 obliquely downwards, and the conveying device 2 includes a push plate 2a that is horizontally attached to the upper surface of the baffle 1f and can drive the push plate 2a on the baffle. 1f is a linkage assembly 2b that moves back and forth horizontally and linearly. The top of the upper frame 1a is equipped with a hopper 5 whose output end is attached to the u...

specific Embodiment 3

[0047] refer to Figure 5 to Figure 7 As shown, a soil collection assembly of a fig tree seedling cultivation machine, the soil collection assembly 7 includes a limiting plate group 7a that can circle the nutrition bag 9 and a clamping assembly 7b for clamping the seedlings 8, the The clamping assembly 7b is horizontally arranged in the limiting plate group 7a, and the limiting plate group 7a includes a first limiting plate 7a1 and a second limiting plate 7a2 which are both curved plates and have opposite openings. The assembly 7b includes a positioning rod 7b1 fixed on the inner middle of the first limiting plate 7a1 and a clamping rod 7b2 that can slide with the middle section of the second limiting plate 7a2. The positioning rod 7b1 and the clamping rod 7b2 are horizontally opposite to each other. The opposite end is provided with a clamping part 7b4, and the second limiting plate 7a2 is slid up a certain distance relative to the first limiting plate 7a1, and the nutrition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com