Automatic processing production line for heat-retaining cribs

An automatic processing and production line technology, applied in the direction of metal processing equipment, wood processing equipment, grinding machines, etc., can solve the problems of not having high temperature function, not satisfying consumers and manufacturers, not having mechanical configuration of assembly and heat preservation parts, etc., and achieving mechanization high level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

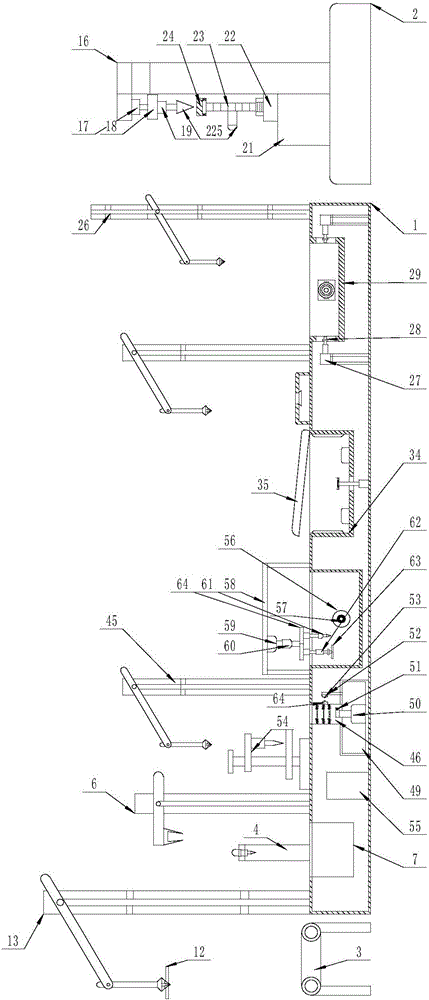

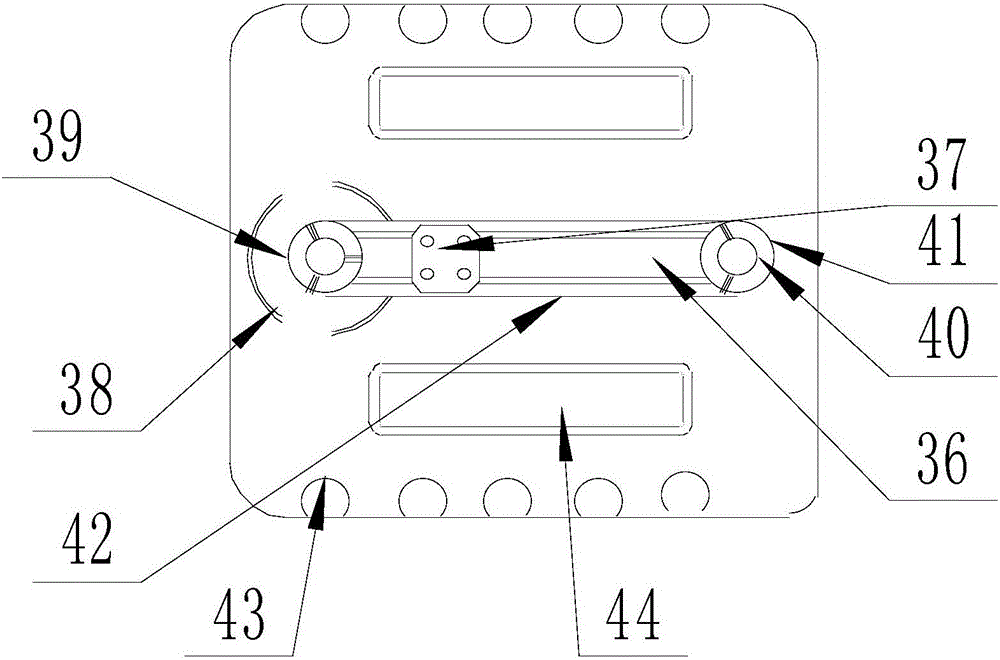

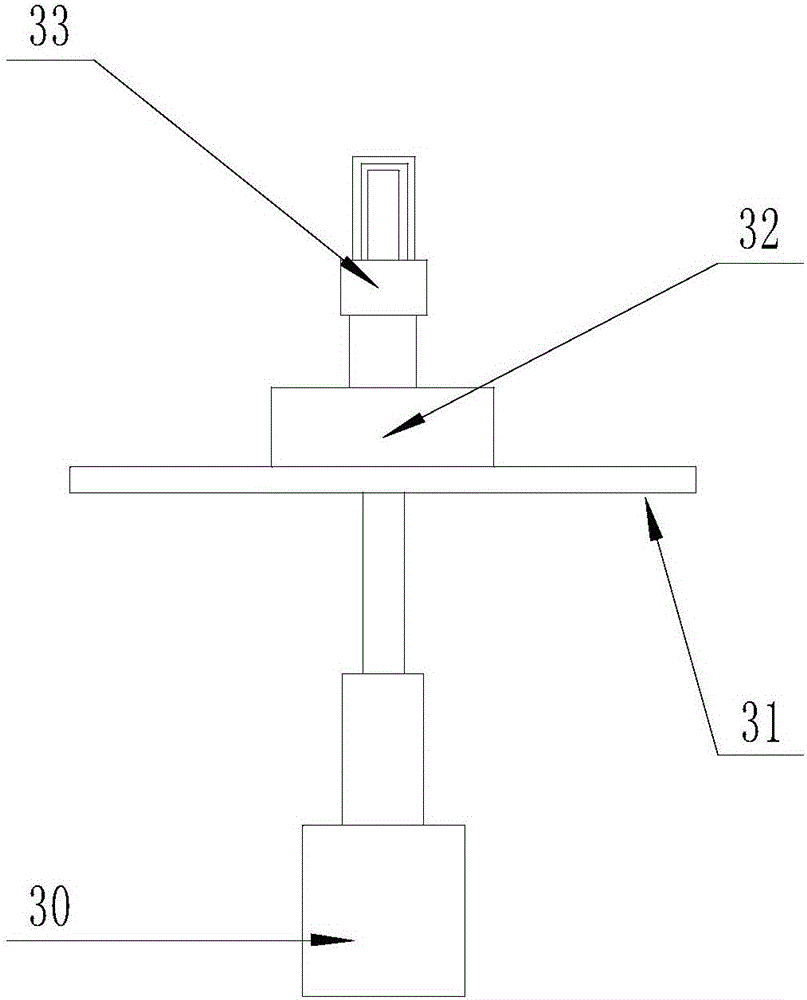

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown in the figure, an automatic processing production line for thermal insulation cribs, the workbench (1) and the base (2) arranged on one side of the workbench (1) and the other side of the workbench (1) are used to transfer the heater Conveyor belt (3), the interior of the worktable (1) is a cavity structure, a vertical arm (4) is provided on one side of the main worktable (1), and a mounting plate is provided on the vertical arm (4) (5), the workbench (1) is provided with a pair of No. 4 mechanical arms (6), the upper surface of the workbench (1) is provided with a fixing groove (7), and the mounting plate (5) is provided with A slide rail (8), the slide rail (8) is embedded with a connecting body (9) that can reciprocate along its length direction, the connecting body (9) is provided with a No. 3 linear motor (10), and the three A planer (11) is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com