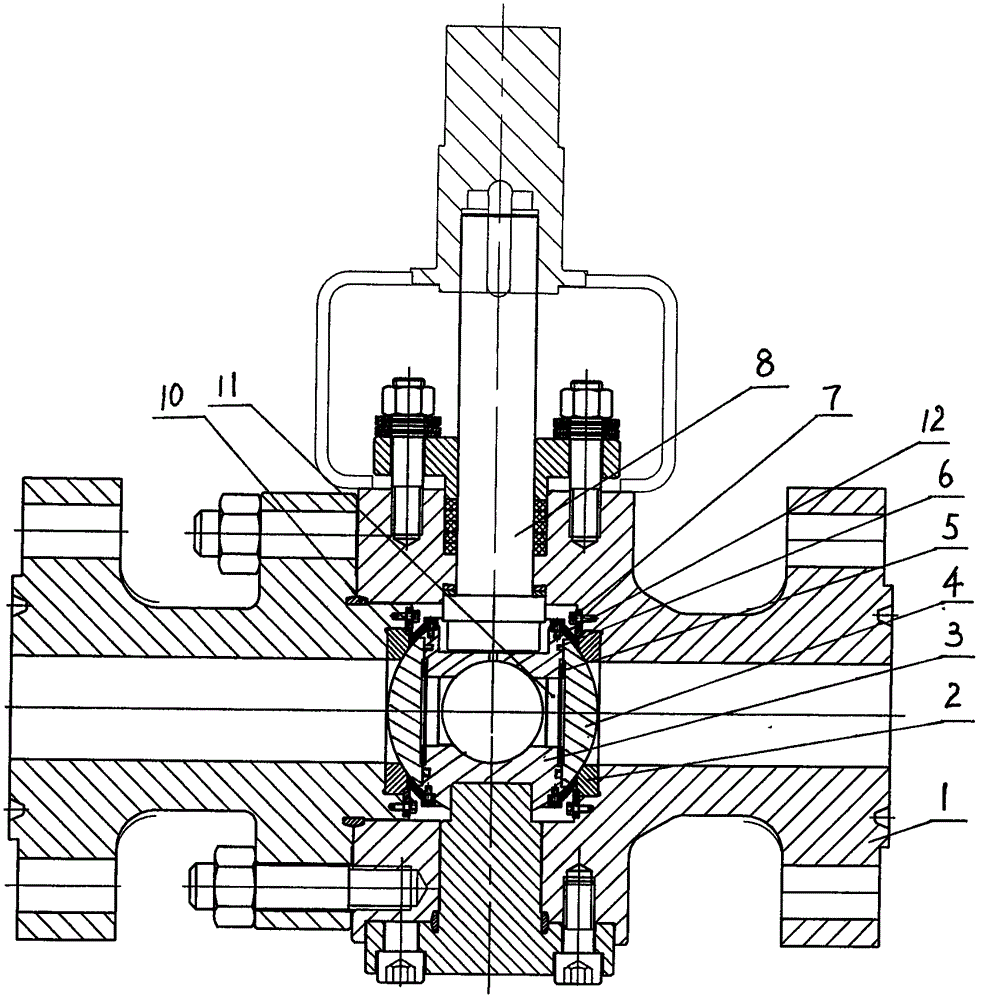

Floating spherical crown dredge type metal sealing ball valve

A technology of metal sealing and floating balls, which is applied in the direction of valve devices, engine components, cocks including cut-off devices, etc., can solve the problems of floating valve seats losing their floating function, jamming, high temperature swelling of balls and valve seats, etc., to prevent Stuck, ensure flexible floating, prevent deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

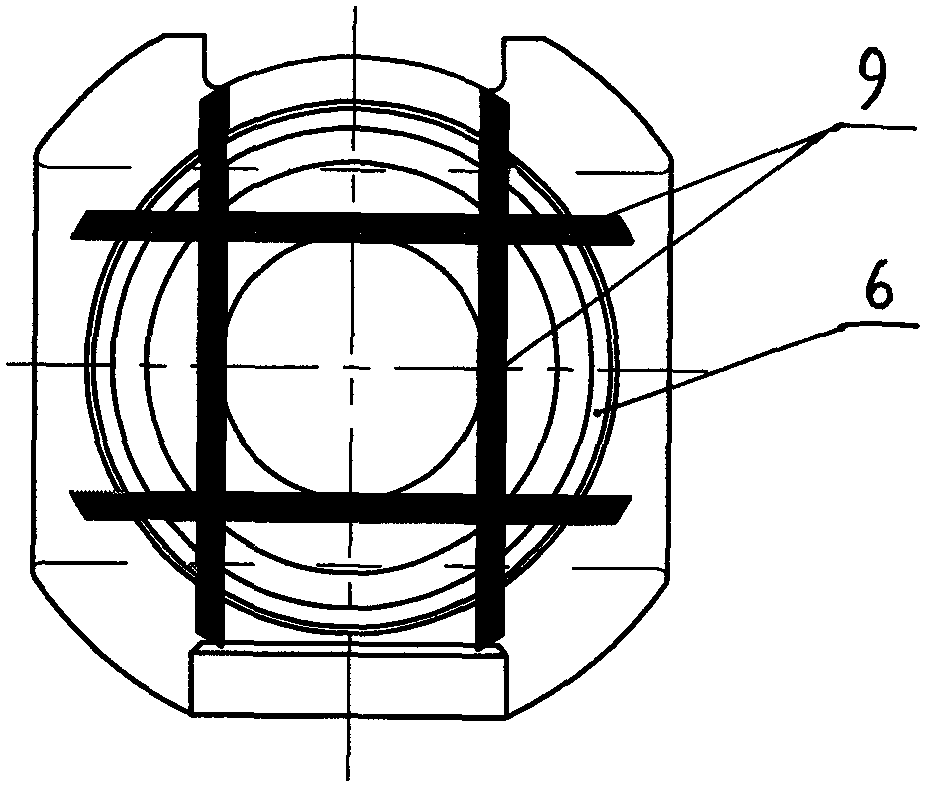

[0010] Such as figure 1 The floating spherical crown dredging metal seal ball valve shown includes valve body 1, valve seat 2, ball 3, valve stem 8, valve seat 2 is respectively arranged in the inlet and outlet passages of valve body 1, and valve body 3 is made with valve body 1 through holes with the same diameter, the sealing surface of the valve seat 2 and the surface of the ball 3 are sprayed with wear-resistant materials, and the inner surface of the through hole of the ball 3 is sprayed with wear-resistant materials; there are two planes on both sides of the through hole of the ball 3, and the two planes Symmetrically arranged on the sphere 3 on both sides of the plane where the centerline of the valve stem 8 and the centerline of the through hole of the sphere 3 are located, and the three planes are parallel to each other, that is, the plane where the centerline of the valve stem 8 and the centerline of the through hole of the sphere 3 are located and the sphere The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com