Saw-swinging type bag breaker

A bag-breaking machine and swing-saw-type technology, which is applied in the field of swing-saw-type bag-breaking machines, can solve the problems of operator hazards, irregular garbage bag shapes, time-consuming and labor-intensive efficiency, etc., and achieve the effect of improving efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

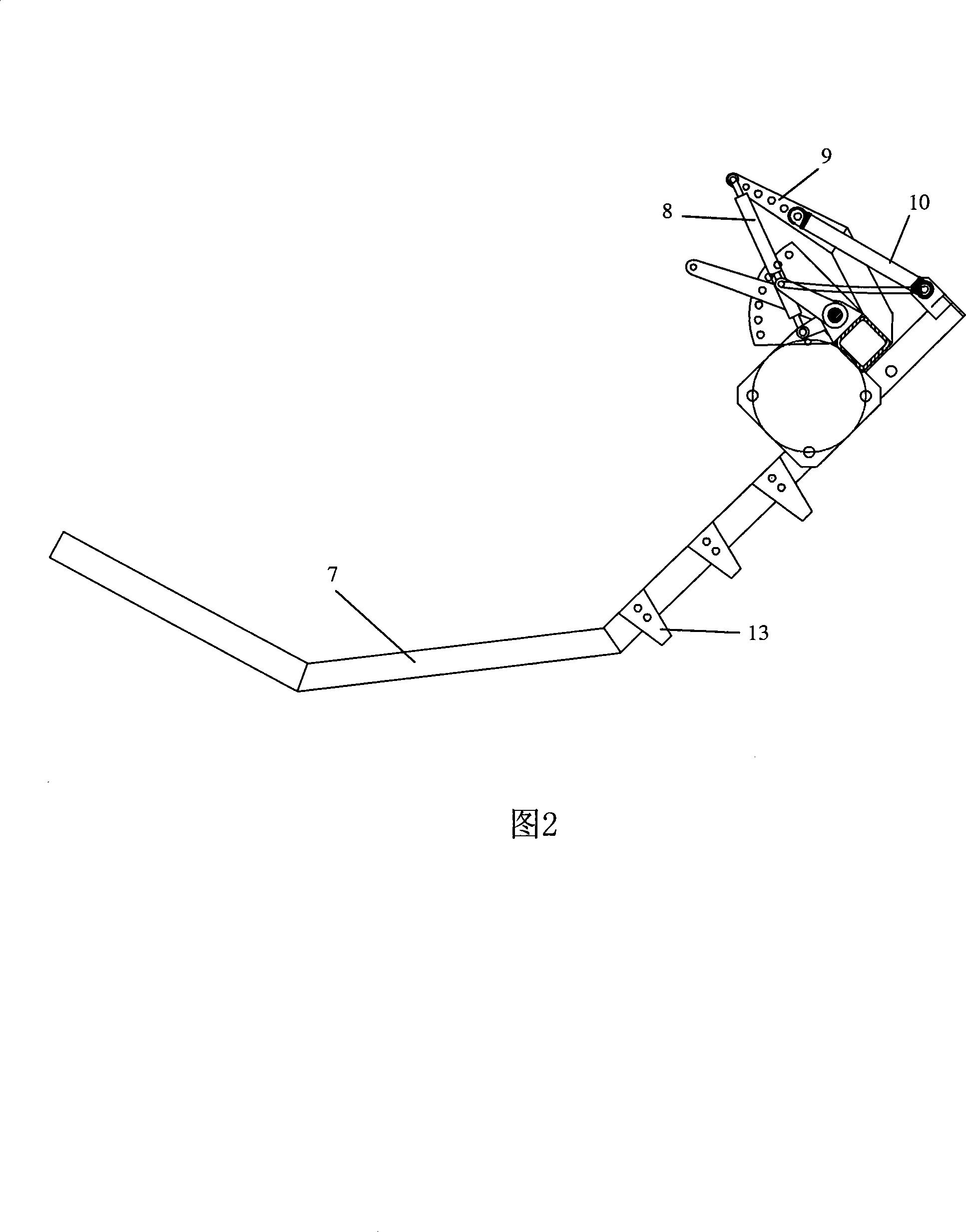

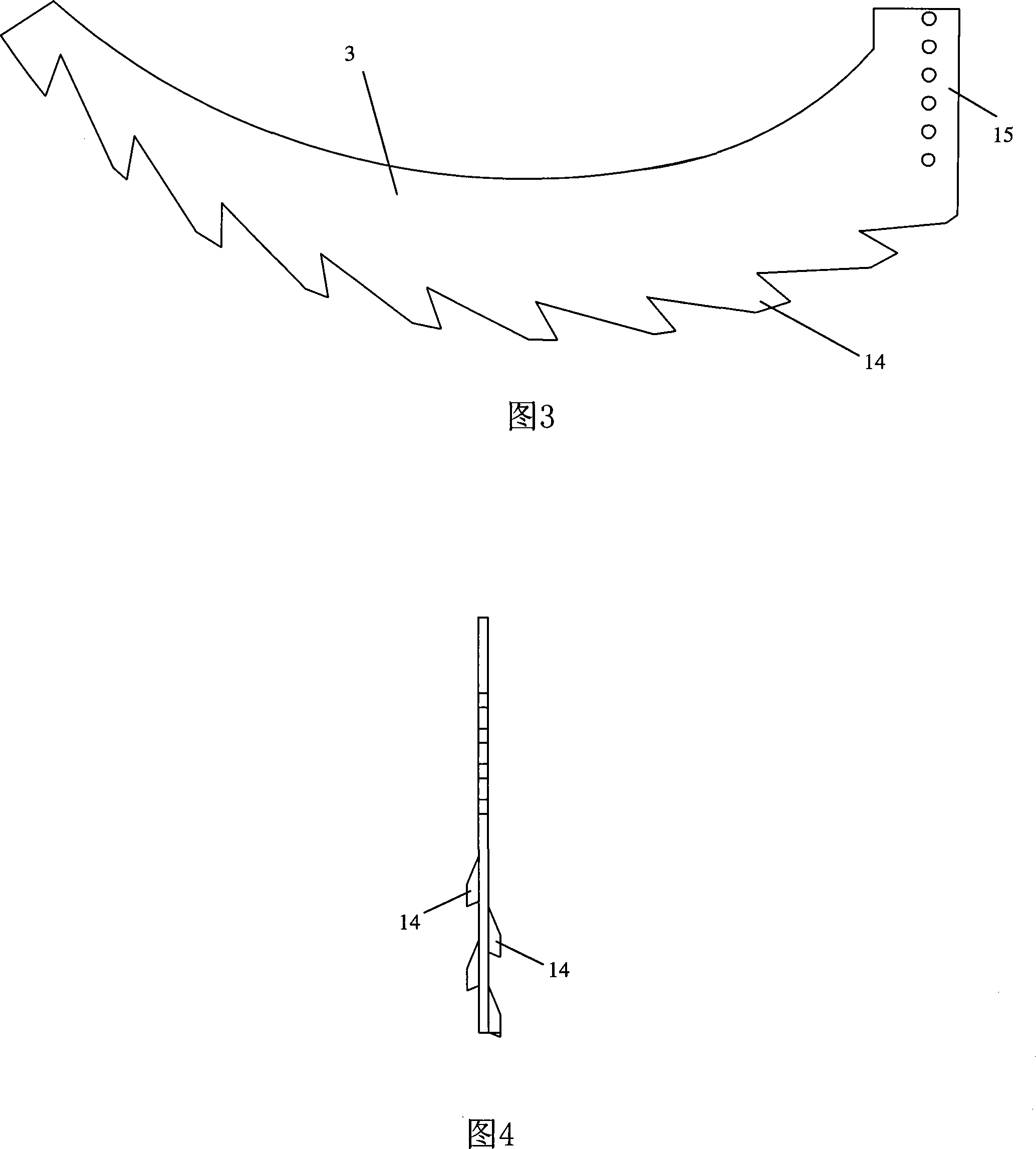

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

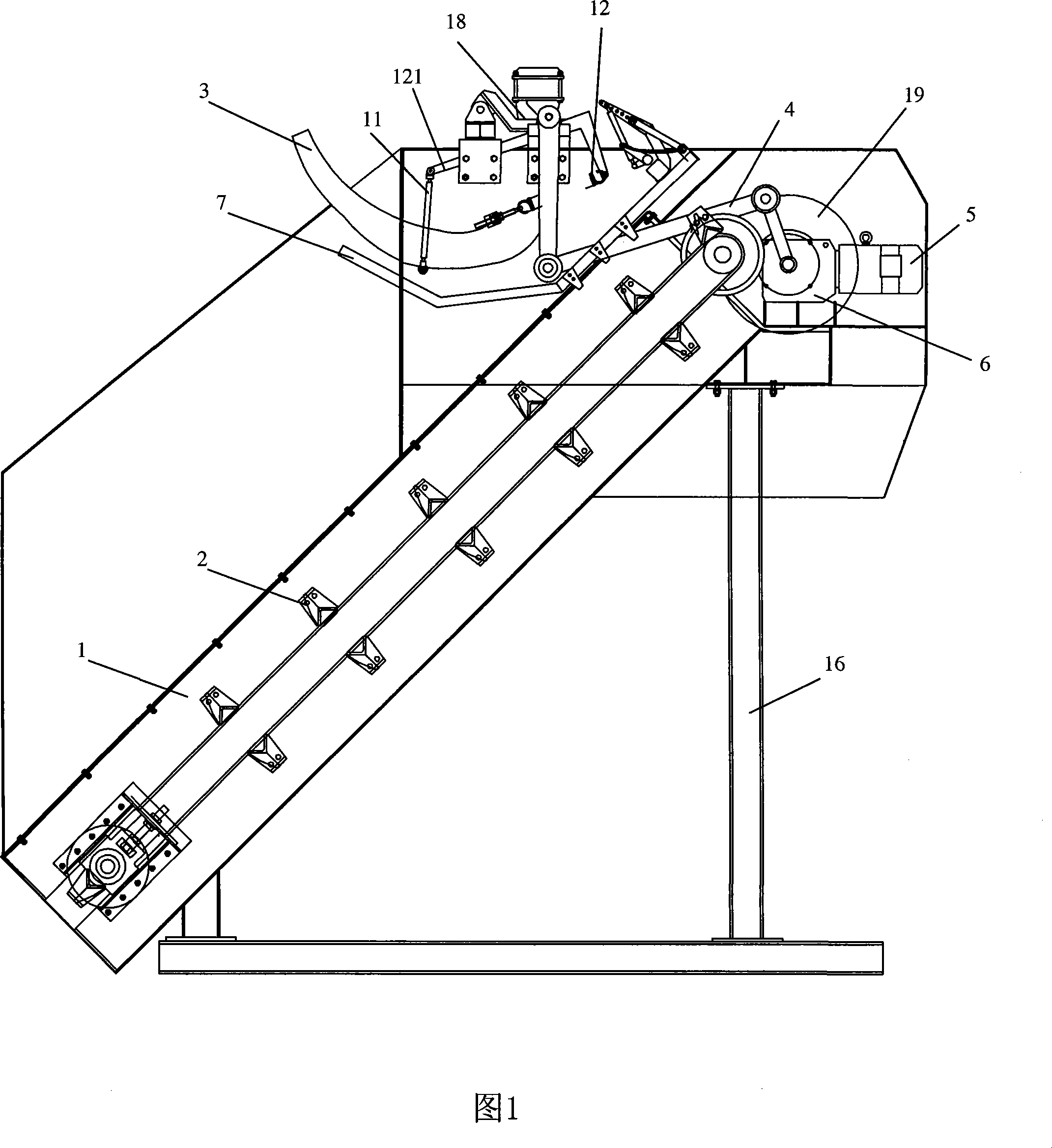

[0031] As shown in Figure 1, it is a preferred embodiment of the swing saw type bag breaking machine of the present invention.

[0032] Plate-toothed conveyor 1 (slab-toothed conveyor is mainly composed of a drive shaft, a tension shaft, a conveyor belt made of UPVC boards, a conveyor chain, a set of connecting pieces (which can be made of angle steel) arranged at intervals along the longitudinal direction of the conveyor belt, and each connection A row of stoppers 2, motors, reducers, etc. are fixed at intervals on the piece) and are inclined at 45° on the support 16. The stoppers 2 can effectively prevent the solid waste bag from rolling down, and can also play the role of breaking the bag. Wherein the connecting piece can be cut into sections with appropriate lengths by using profiles (such as angle steel), the block 2 is fixed on the connecting piece, and the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com