Bait casting machine for net cage aquaculture

An aquaculture and feeding machine technology, applied in fish farming, application, climate change adaptation and other directions, can solve the problems of high labor intensity, death of fish due to lack of oxygen, nutritional imbalance, etc., and achieve reasonable structure and layout, easy to add Feed, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

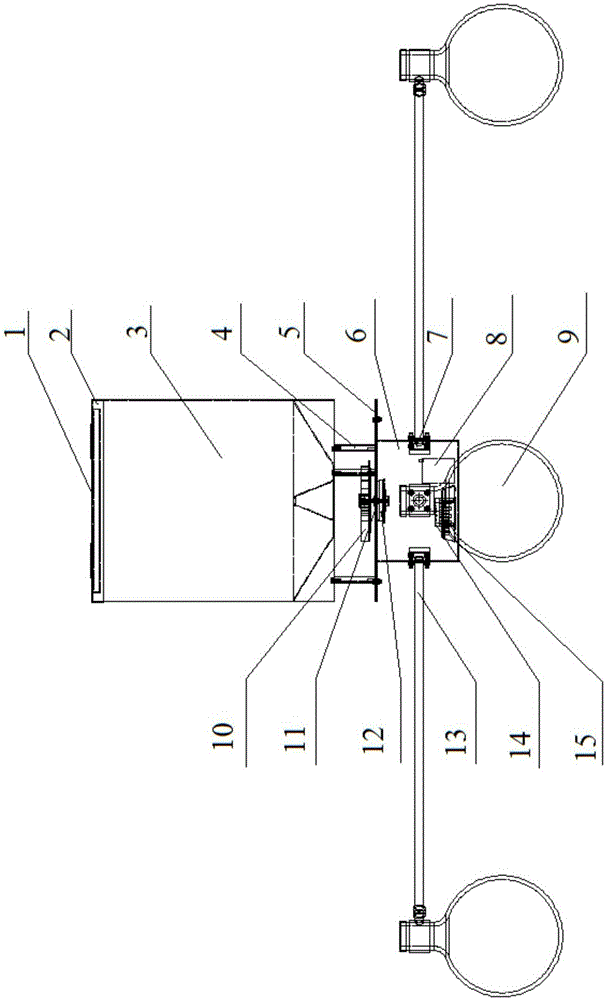

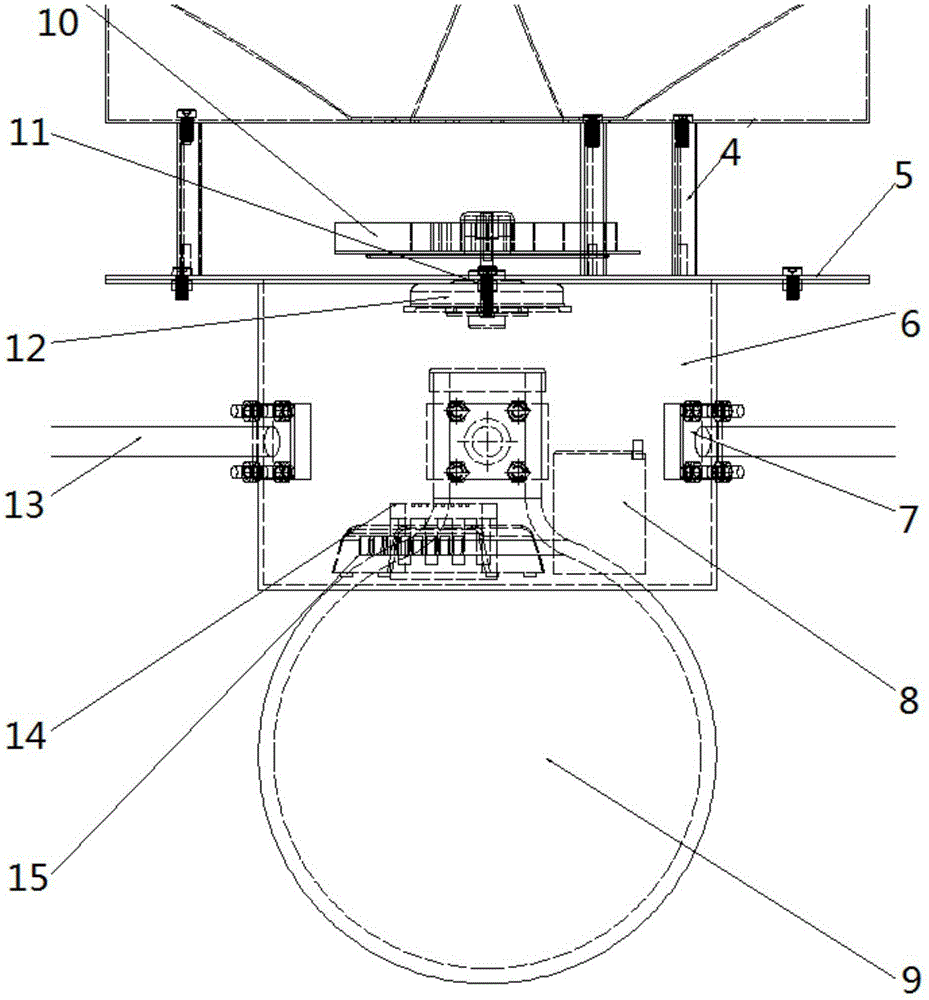

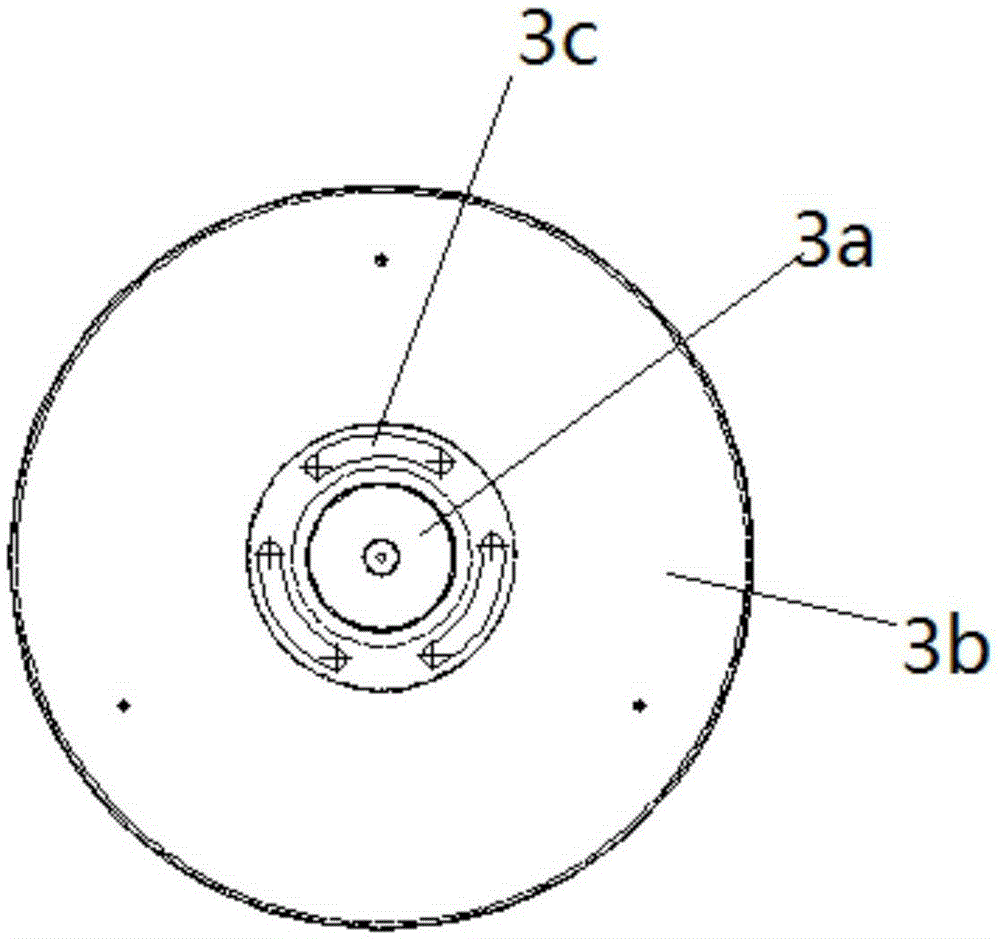

[0034] see Figure 1-Figure 6 , a net cage aquaculture bait throwing machine, the net cage aquaculture bait throwing machine includes a feed box 3, a buoyancy mechanism, a material throwing tray 10, a material throwing motor 10, a time relay 14, and a frequency conversion controller; The mechanism supports the net cage aquaculture bait thrower so that it floats on the water surface in the net cage; the center of the bottom surface of the material box 3 is provided with an upwardly protruding conical guide platform 3a, and the material box 3 A correspondingly inclined deflector 3b is provided around the bottom surface of the base; a plurality of arc-shaped discharge holes 3c are evenly distributed in the annular area between the deflector 3b and the deflector 3a; below the discharge hole 3c The throwing tray 10 is fixedly arranged, and the bait...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com