Trolley type fully-mechanized coal mining hydraulic support assembling frame

A technology of hydraulic support and assembly frame, which is applied to mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of slow assembly, insufficient strength of square pipe column, limited lifting height of components, etc., and achieve the effect of high lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

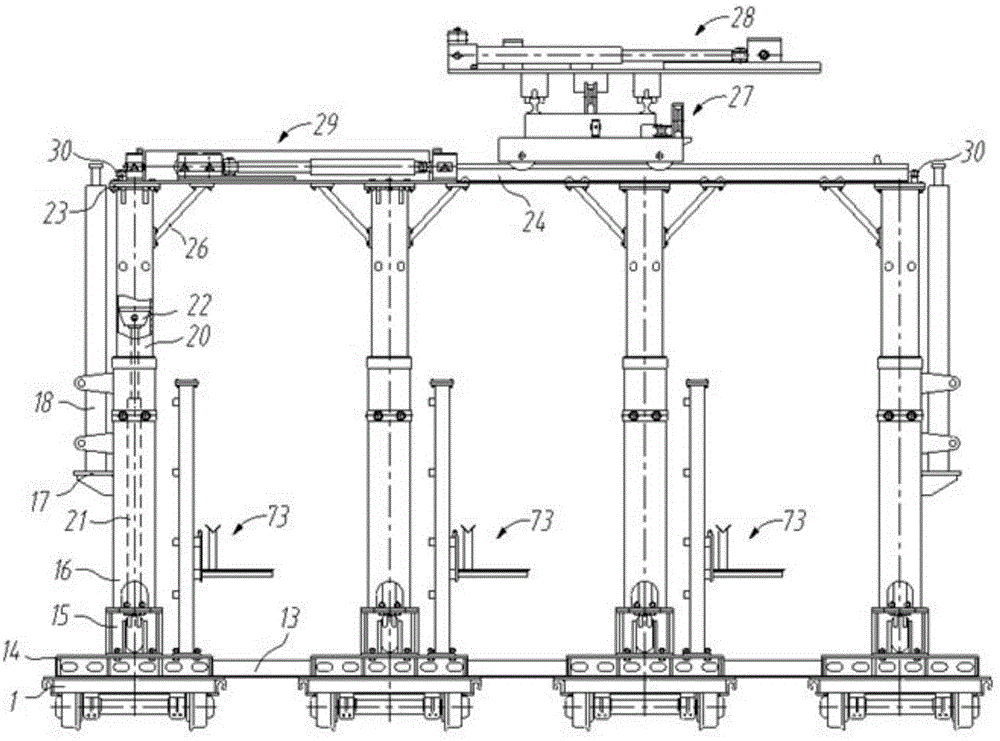

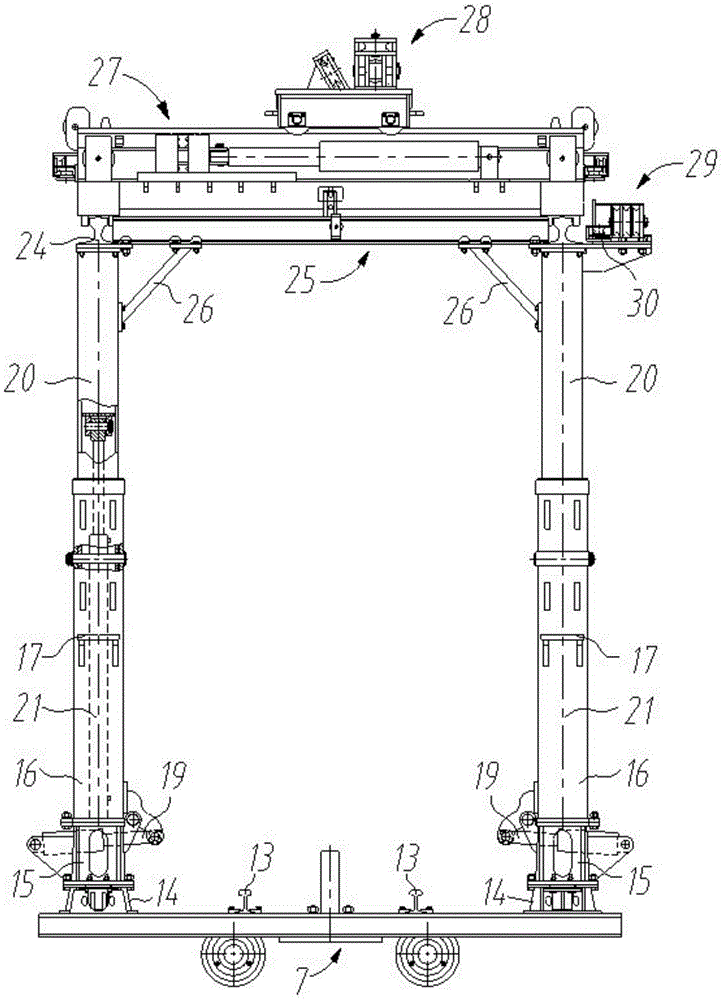

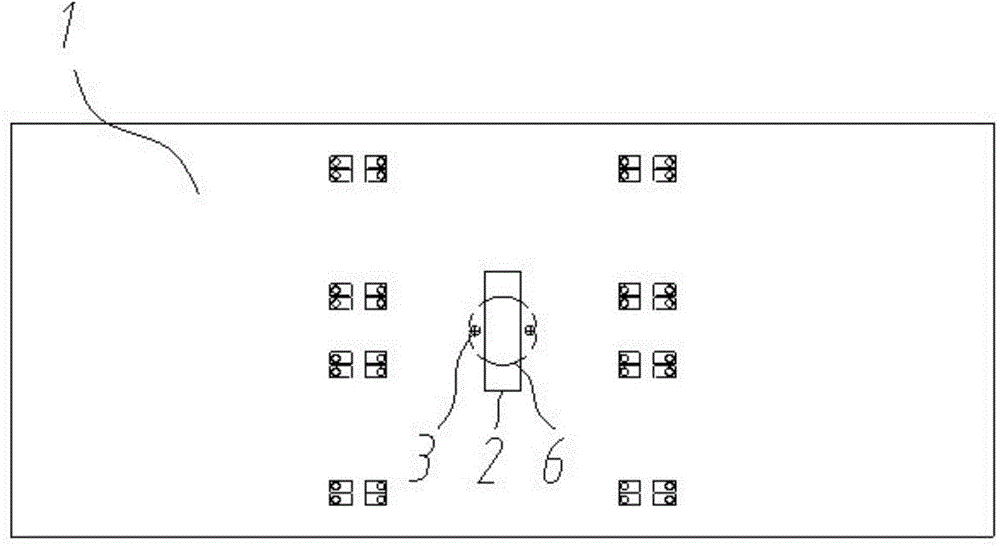

[0034] Such as Figure 1 to Figure 6 As shown, a sports car-type fully mechanized mining hydraulic support assembly frame includes four assembly unit frames, a longitudinally moving sports car, a longitudinally moving traction device and a lifting sports car. There is a rectangular slotted hole 2 in the middle of the upper end surface of the upper end surface, and a circular hole 3 is respectively opened on both sides of the rectangular slotted hole 2. The circular hole 3 is connected with a vehicle body rotating hydraulic cylinder 5 with a screw 4, and the lower end surface of the flatbed truck 1 is opened. There is an axle hole 6, and there is a vehicle body rotating device 7 in the middle of the flatbed truck 1. The vehicle body rotating device 7 has a base plate 8 supporting the ground, and a support seat 9 and an anti-off end cover 10 are arranged on the base plate 8, both of which are connected by screws 11 connection, the support seat 9 is provided with a hinged hole 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com