Roller bed conveying device

A technology of conveying device and roller table, which is applied in the direction of roller table, transportation and packaging, etc. It can solve the problems of complex installation, high manufacturing cost, processing and complicated structure of roller table bracket, and achieve the effect of stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

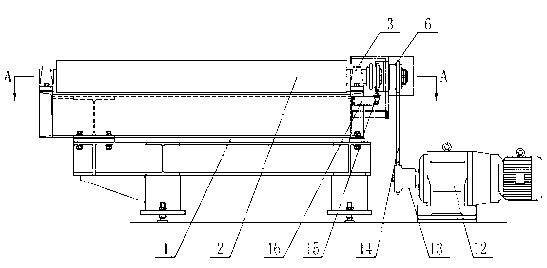

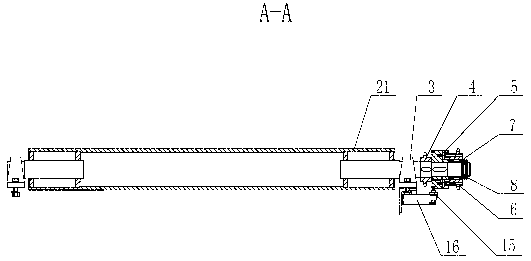

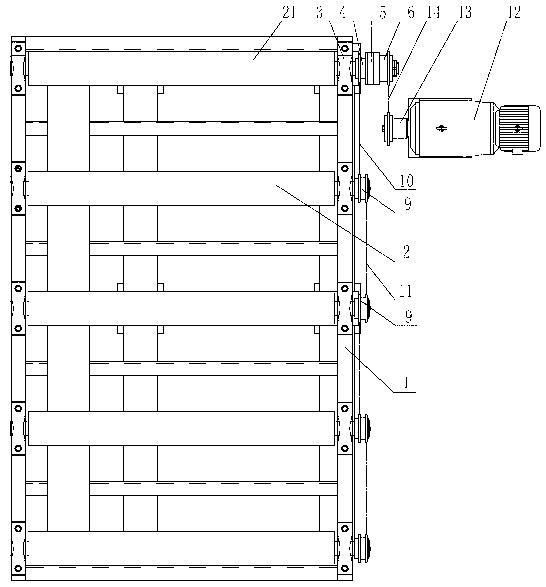

[0016] See figure 1 , the present invention comprises a frame 1, a roller 2 and a geared motor 12 outside the frame 1, and the two ends of the roller 2 are mounted on the frame 1 through bearing blocks 3; see figure 2 , image 3 , the shaft end on one side of the first roller 21 is sequentially connected with the first sprocket 4 and the electromagnetic clutch 5 through a key connection, the electromagnetic clutch 5 adopts a jaw type electromagnetic clutch, and the second sprocket 6 is mounted on the first sprocket through a bearing 7. The shaft end on one side of the roller 21 is locked by a round nut 8, the second sprocket 6 is connected to the clutch end of the electromagnetic clutch 5, and the lower end of the electromagnetic clutch 5 is in contact with the electric brush 15, and the electric brush 15 is installed on the fixed frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com