Planar motion mechanism for water ship model maneuverability test

A technology of plane motion mechanism and maneuverability test, which is applied in fluid dynamics test, testing of machine/structural components, measuring device, etc. It can solve the problem of inability to measure the acceleration coefficient, so as to promote the research of fluid dynamics test and achieve good economy. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

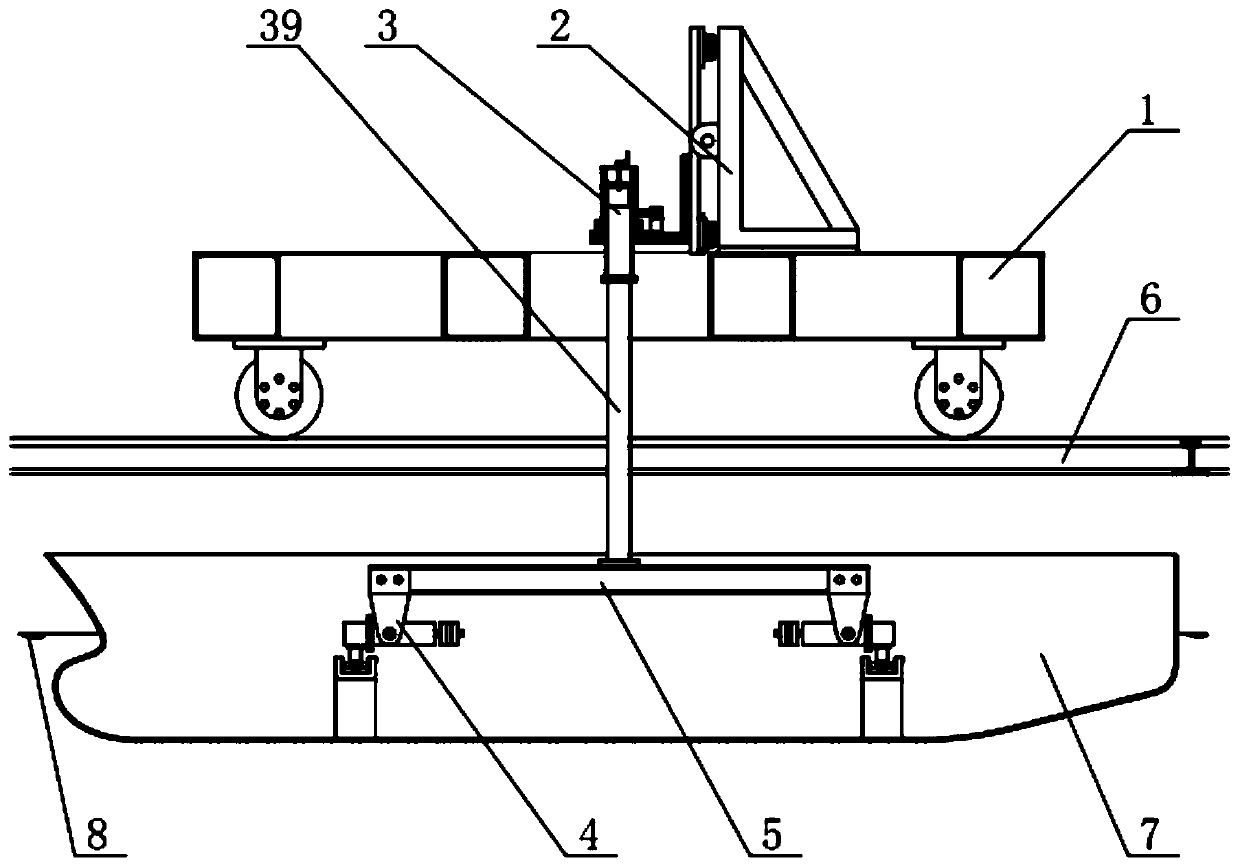

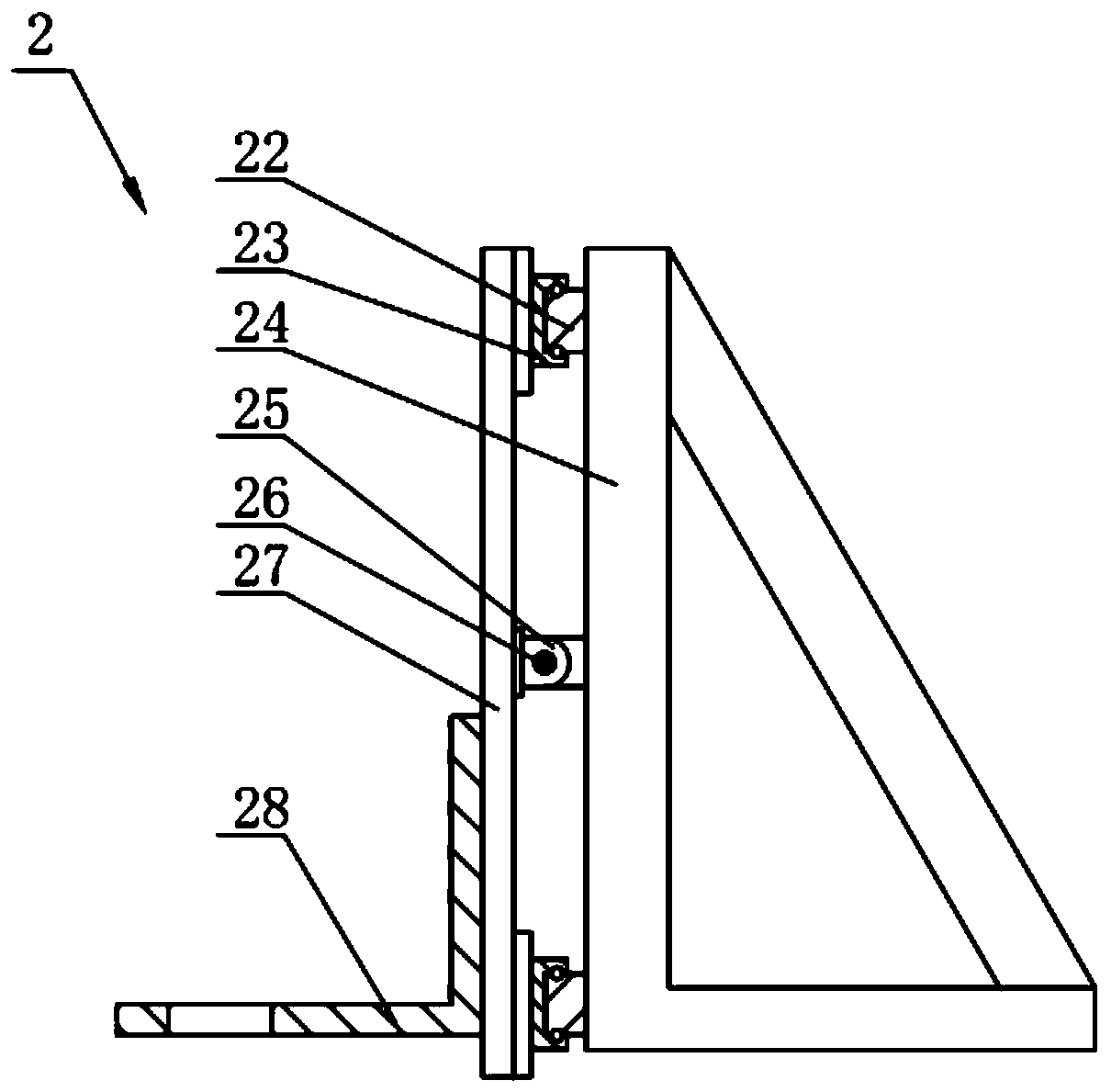

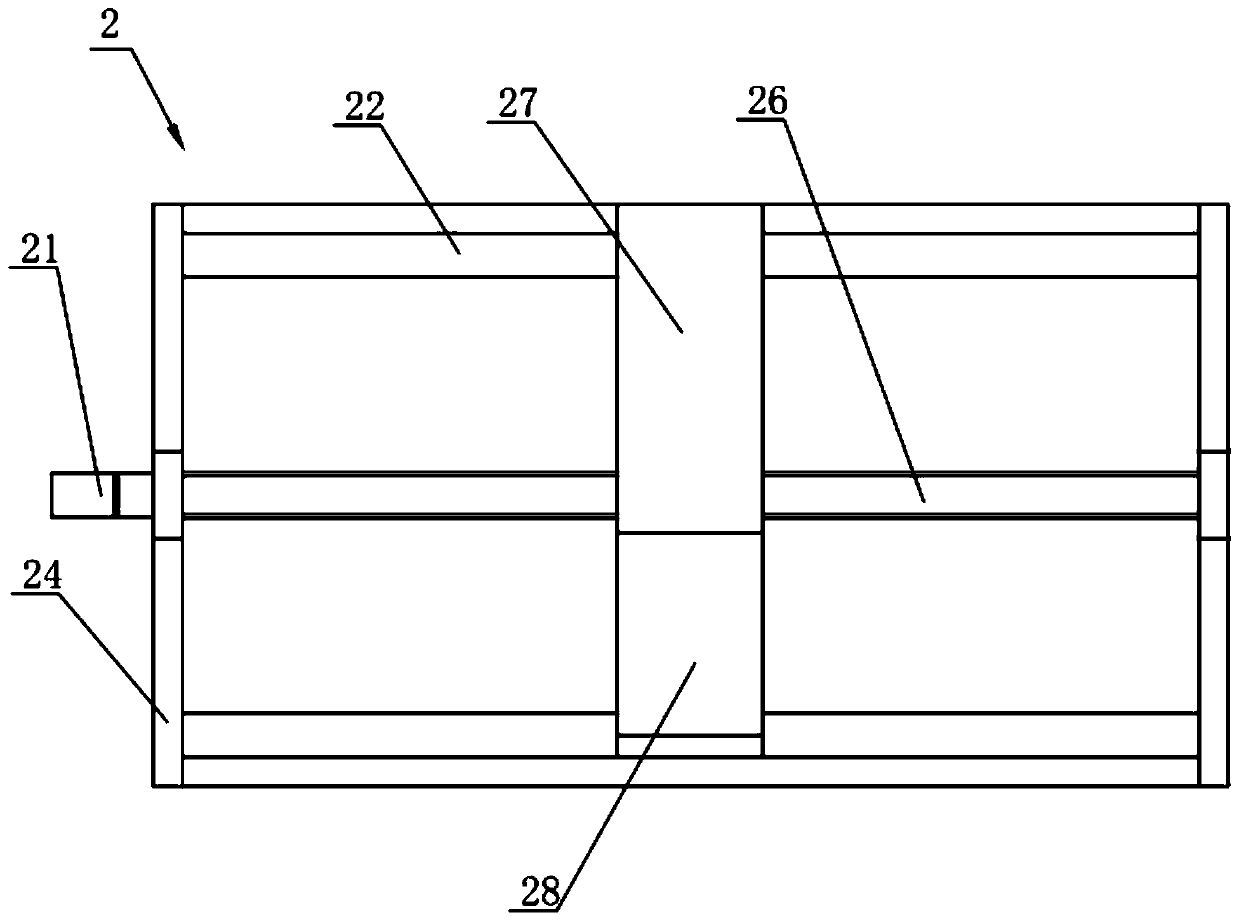

[0033] like figure 1 As shown, the planar motion mechanism used for the maneuverability test of the water surface ship model in this embodiment includes a trailer 1, the trailer 1 moves along the track 6 under its own power, and a ship model 7 is arranged under the trailer 1, and the ship model 7 is placed on On the water surface 8, a swaying mechanism 2 is installed on the trailer 1, and an adjusting mechanism 3 is installed on the swaying mechanism 2; a symmetrical balance force-measuring mechanism 4 is fixedly installed on the ship model 7 along the front and rear directions, and two balances measure force A crossbeam 5 is connected between the tops of the mechanisms 4; a strut 39 is installed at the bottom of the adjustment mechanism 3, and the strut 39 passes through the trailer 1 and is fixedly connected to the middle of the crossbea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com