a wire take-up device

A wire take-up device and roller technology, applied in the directions of transportation and packaging, thin material handling, and filamentary material transportation, can solve the problems of lengthening the lateral distance between the nozzle and the roller, multi-layered materials, poor rigidity, etc., and improve traction. effect, the effect of reducing the multi-layered material and improving the rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

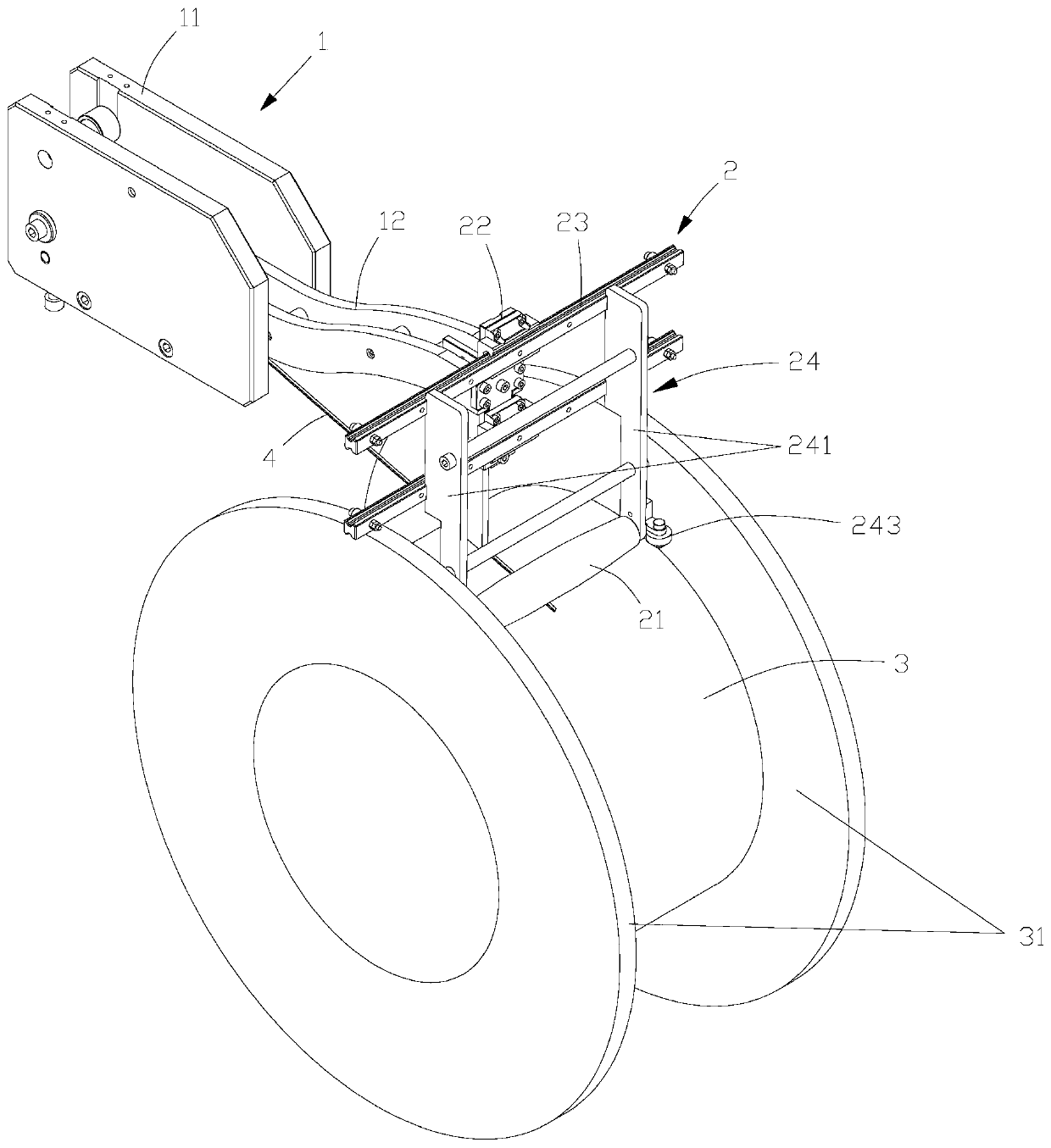

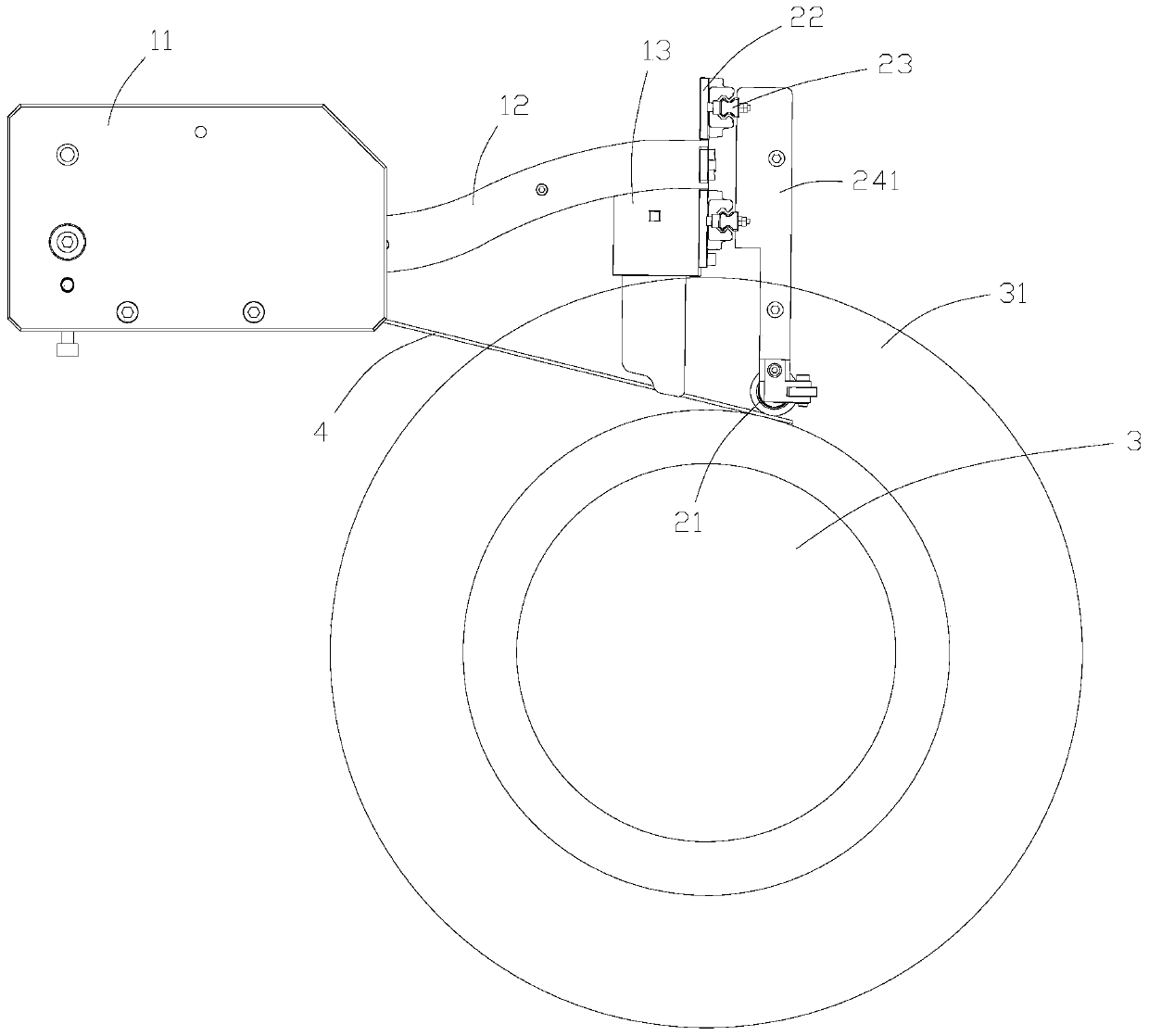

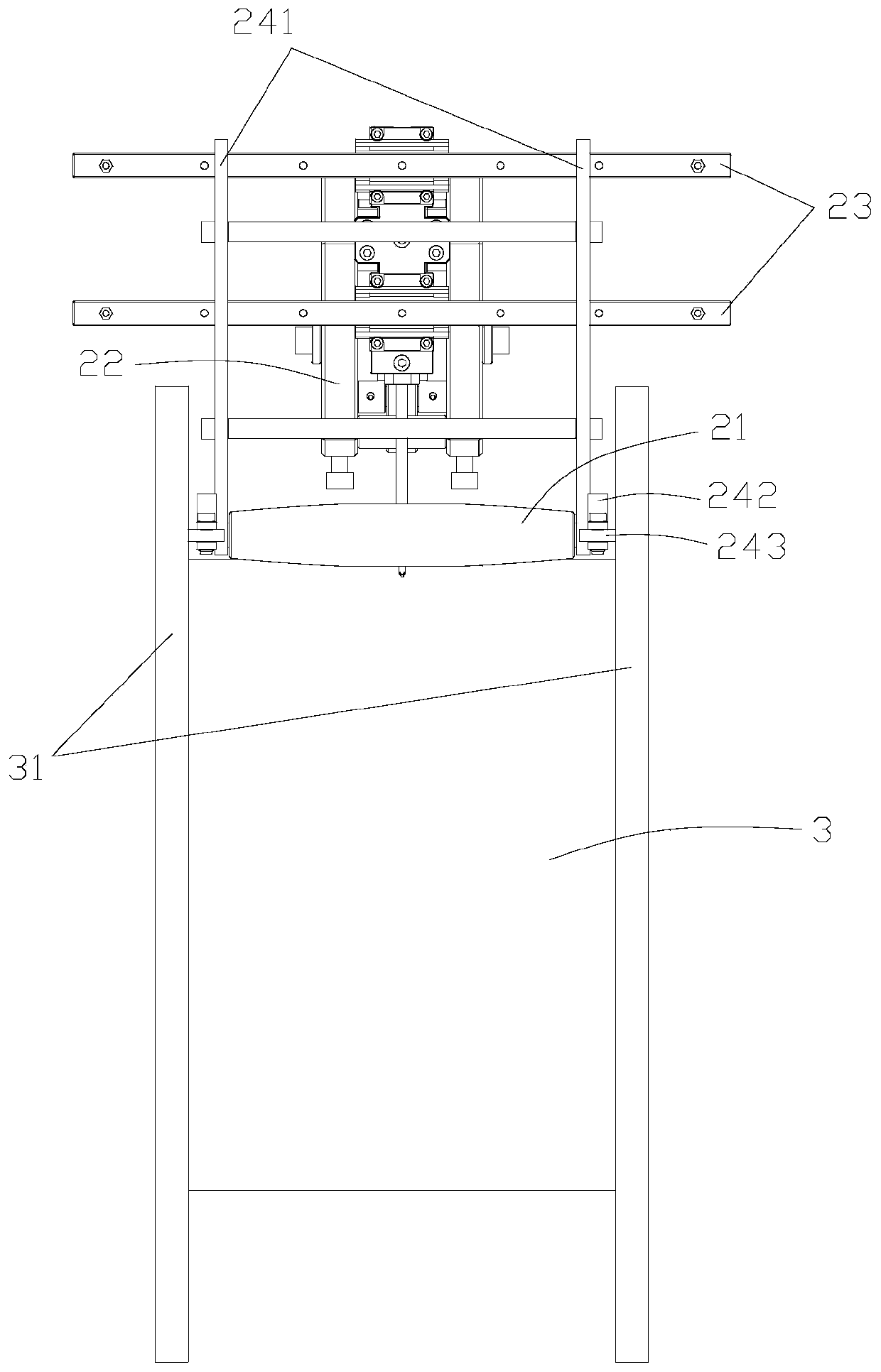

[0020] see Figure 1 to Figure 5 , the present embodiment provides a wire take-up device, including a guiding mechanism 1, a material pressing mechanism 2, a drum 3 and a driving mechanism (the driving mechanism is not shown in the figure), and the driving mechanism includes a motor for driving the rotating motion of the drum 3 A rotation drive mechanism and a translation drive mechanism that drives the drum 3 to move periodically in axial translation. The guide mechanism 1 includes a material guide base 11, a connecting rod 12 and a nozzle 13. The head end of the connecting rod 12 is hinged to the material guide base 11, so that the connecting rod 12 can reciprocate in the up and down direction. , the material nozzle 13 is located at the end of the connecting rod 12, the lower end of the material nozzle 13 is provided with a material hole 131, the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com