Multidirectional Fluid Drive System Based on Pressure Control and Its Application

A technology of fluid flow direction and pressure, applied in the field of microfluidics, can solve problems such as incompatibility, and achieve the effect of improving efficiency and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

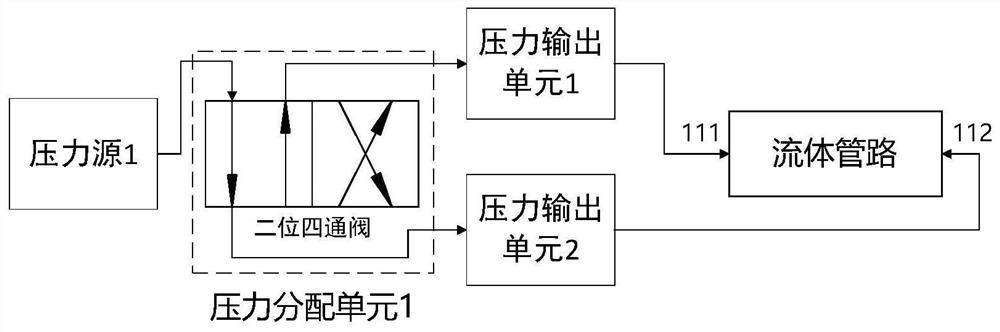

[0022] Embodiment 1: A two-way fluid drive system

[0023] figure 1 The left half of the figure is a schematic structural diagram of a two-way fluid drive system, which includes: a pressure source 1, a pressure distribution unit 1 and two pressure output units 1-2. The pressure in the pressure source 1 is higher than the atmospheric pressure; the pressure distribution unit 1 includes a two-position four-way valve, one of its air inlets is connected to the pressure source 1, the other air inlet is connected to the atmosphere, and the two air outlets are respectively connected to Two pressure output units 1-2; two pressure output units 1-2 are respectively connected to figure 1 The fluid pipe ends 111 and 112 of the right half.

[0024] When the two-position four-way valve is in the normal position, the pressure of the pressure source 1 is connected to the 111 end of the fluid pipeline by the pressure distribution unit, and the atmospheric pressure is connected to the 112 end ...

Embodiment 2

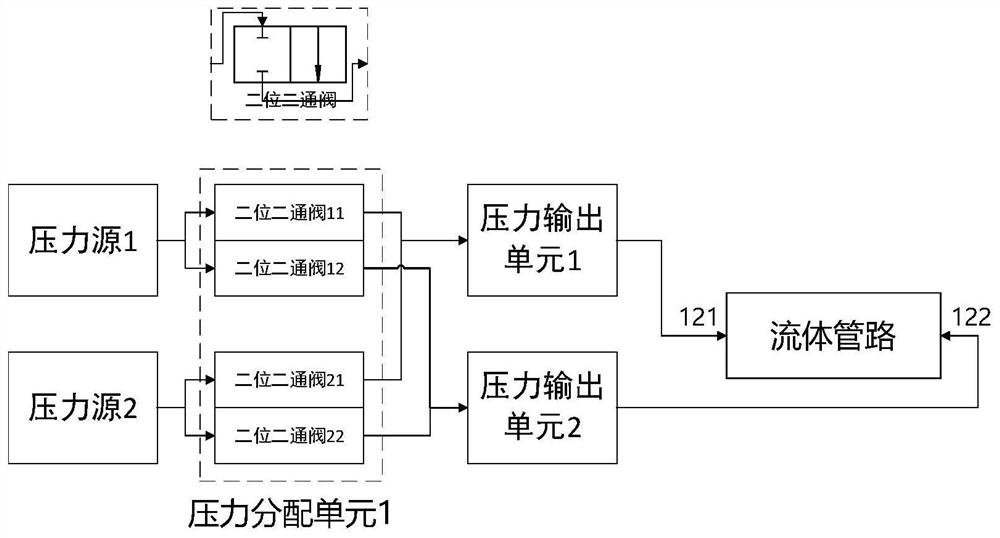

[0026] Embodiment 2: A two-way fluid drive system

[0027] figure 2 The left half of the figure is a schematic structural diagram of a two-way fluid drive system, which includes: two pressure sources 1-2, one pressure distribution unit 1 and two pressure output units 1-2. The pressure in the pressure source 1 is higher than the pressure in the pressure source 2; the pressure distribution unit 1 includes four two-position two-way valves (normal position: close the flow path, working position: connect the flow path), and the numbers are respectively ij= 11, 12, 21, 22, the number ij mentioned indicates that the inlet port of the two-position two-way valve is connected to the pressure source i, and the gas outlet is connected to the pressure output unit j; the two pressure output units are respectively connected to figure 1 The two ends 121 and 122 of the fluid conduit of the right half.

[0028] When the two-position two-way valves 11 and 22 are in the working position and th...

Embodiment 3

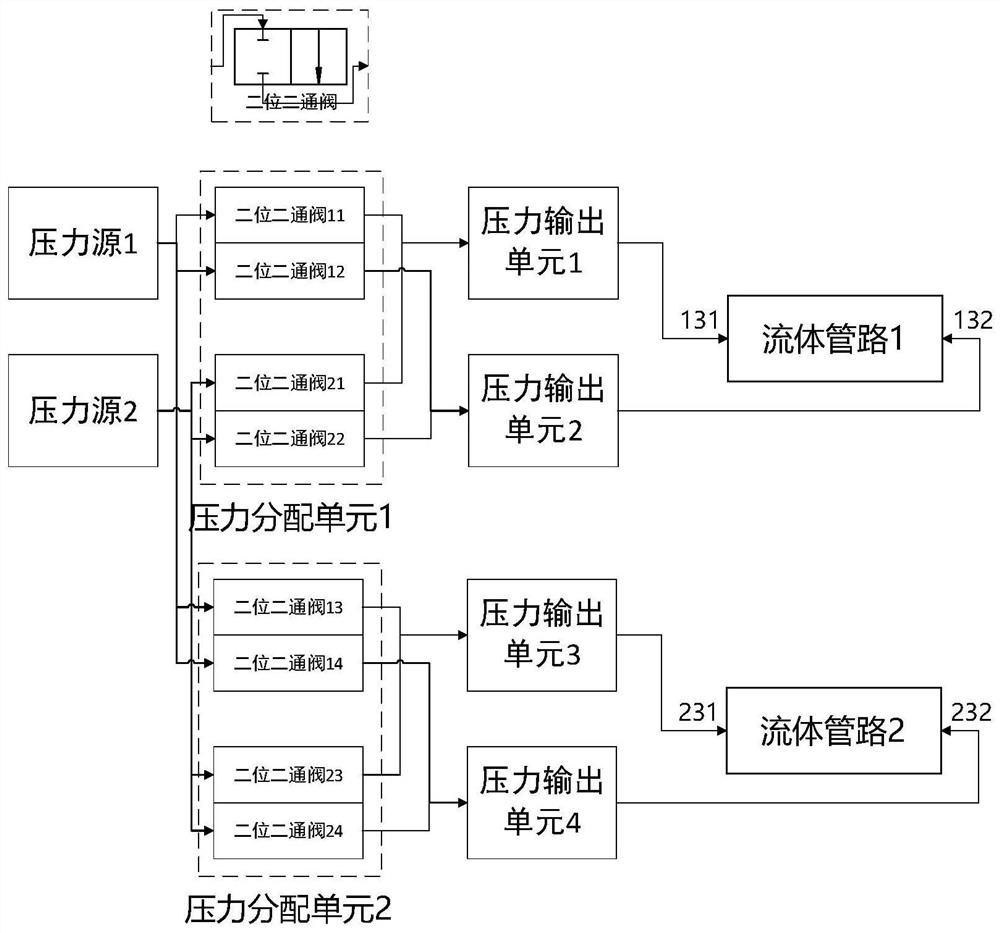

[0033] Embodiment 3: A dual-channel bidirectional fluid drive system

[0034] image 3 The left half of the figure is a schematic structural diagram of a dual-channel bidirectional fluid drive system, which includes two pressure sources, two pressure distribution units and two pressure output units, respectively driving the two fluid pipelines 1-2 in the right half of fluid.

[0035] Similar to Embodiment 2, each pressure distribution unit can independently control the movement direction and movement / stationary state of the fluid in each fluid pipeline: the pressure distribution unit 1 can control the fluid pipeline 1 through the interfaces 131-132 at both ends of the fluid pipeline The pressure at both ends (the pressure of pressure source 1 or pressure source 2), so as to control the movement direction and movement / rest state of the fluid; the pressure distribution unit 2 can control the pressure at both ends of the fluid pipeline 2 through the interfaces 231-232 at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com