Flat knitting machine nose high speed reversing control method and control system thereof

A technology of a control method and a control system, which is applied in the field of a high-speed reversing control method of a flat knitting machine head and its control system, can solve problems such as reducing reversing efficiency, improve reversing efficiency, avoid wasting reversing time, and improve weaving efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

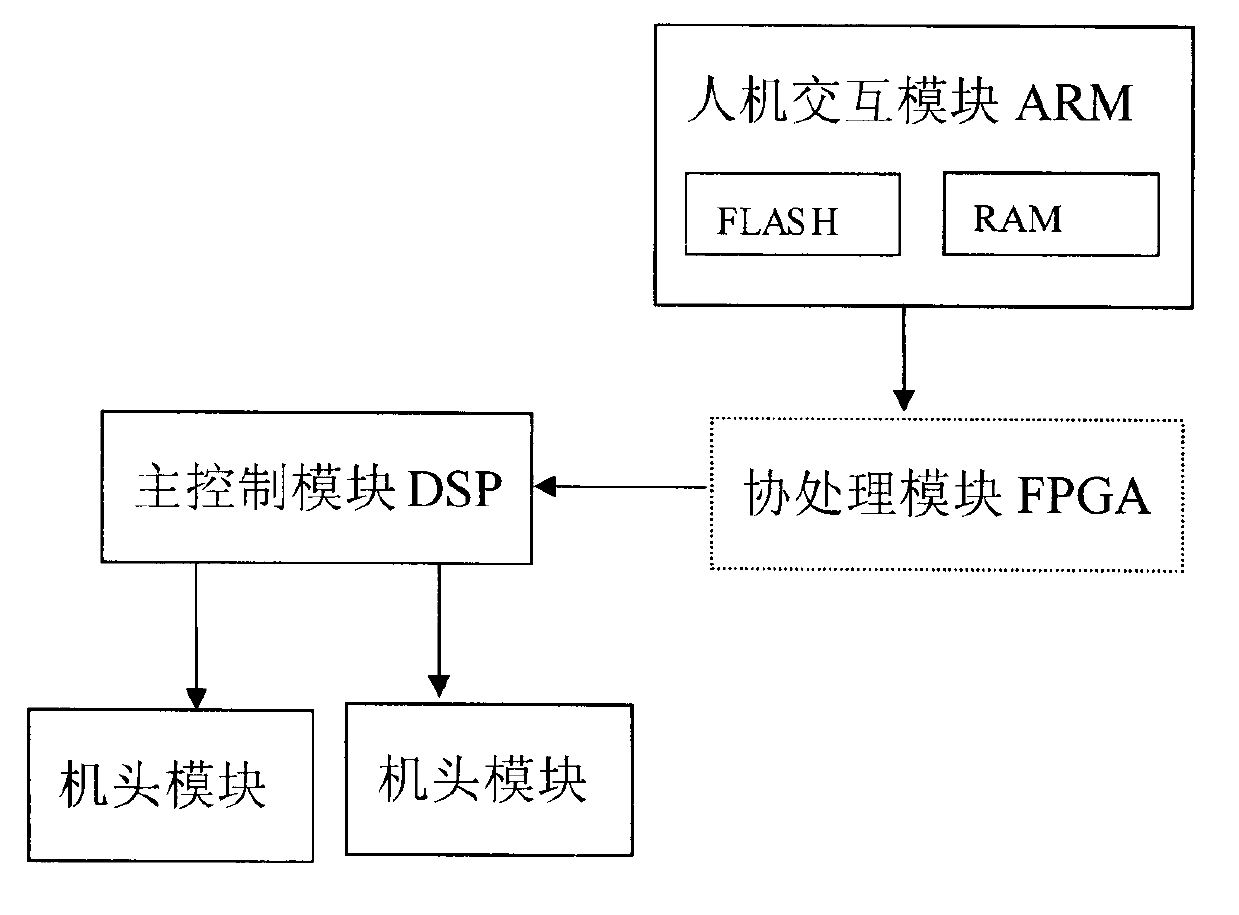

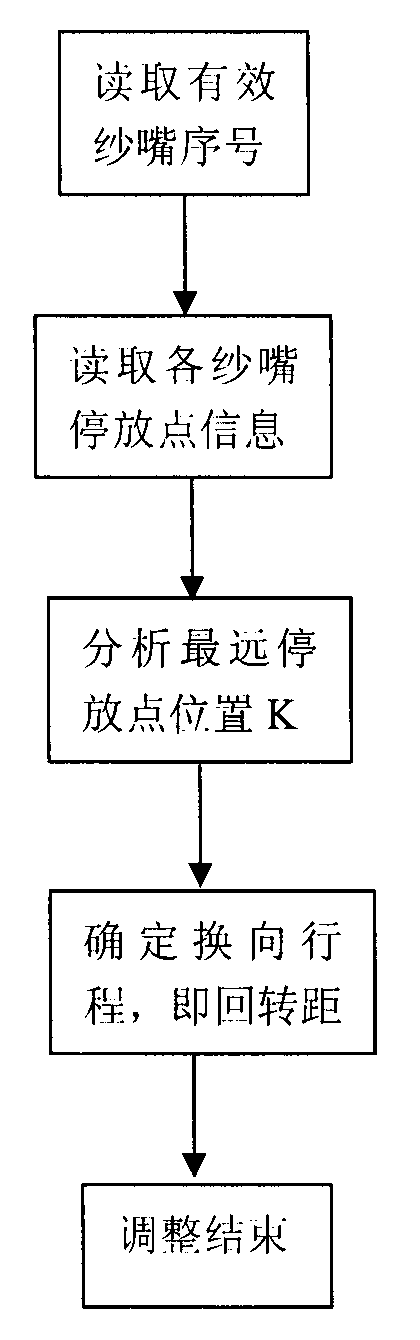

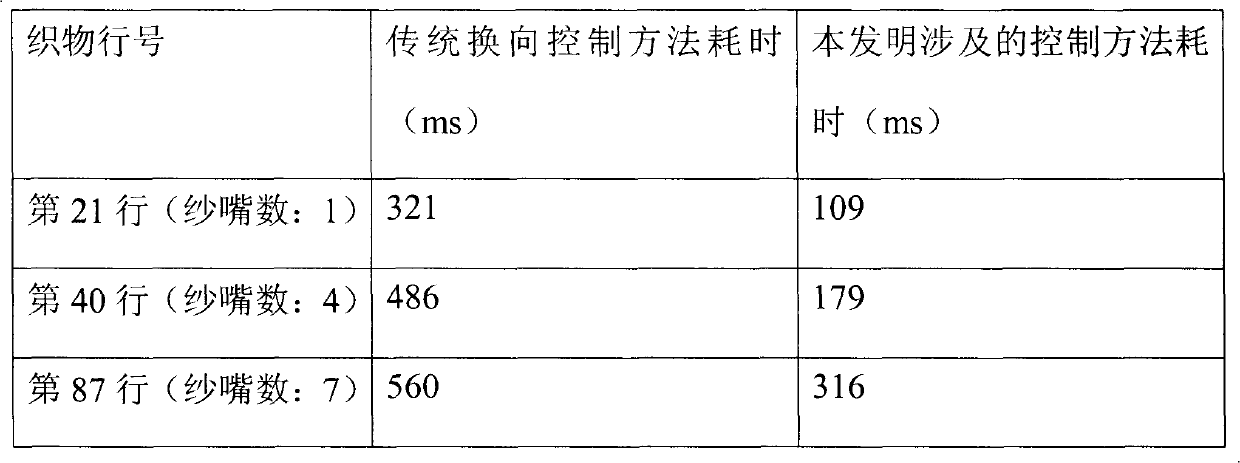

[0023] Embodiment: A kind of high-speed reversing control method of flat knitting machine head, such as figure 2 As shown, the steps include:

[0024] Step 1: Data reading: the main control module reads the movement data of the next stroke of the machine head from the storage module of the human-computer interaction module (ARM), parses and stores the result in the array of the main control module; among them, the human-computer interaction The module includes a FLASH module and a RAM module; the storage module of the human-computer interaction module is a FLASH module; the main control module adopts a module with a digital signal processor DSP as the core processor.

[0025] Step 2: Execute the reversing action: the main control module sends an action command to the head module through the field bus CAN, and the co-processing module (DSP) on the head performs the reversing action according to the command;

[0026] Step 3: Adaptive adjustment of the turning distance: the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com