Weft insertion device and method for multilayer braided prefabricated body

A technology for weft insertion device and preform, which is applied in the directions of textile, loom, textile and paper making, etc., can solve the problems of low weaving efficiency of multi-layer woven preform and single-size weft insertion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

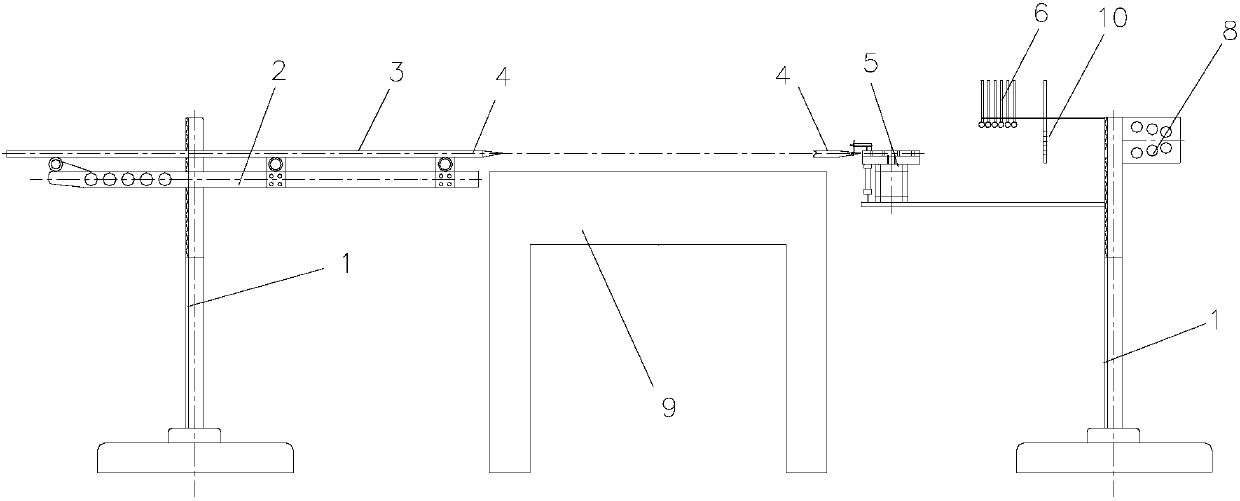

[0049] Such as Figure 1-6 As shown, a weft insertion device for a multi-layer braided prefabricated body includes a support, the support includes a base and a lifting device 1 arranged on the base, and a yarn storage mechanism is sequentially arranged on the lifting device 1 along the advancing direction of the weft insertion yarn bundle 8. Yarn selection mechanism 6, closing mechanism 7, cutting mechanism 5 and traction mechanism 2.

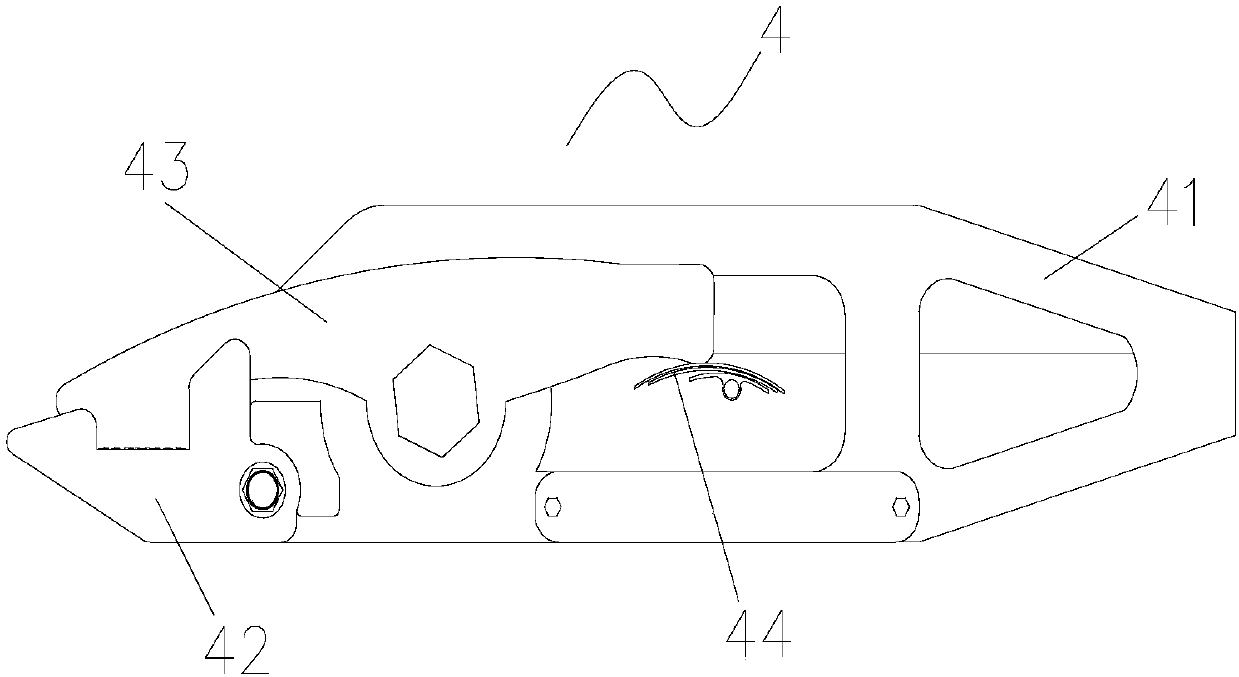

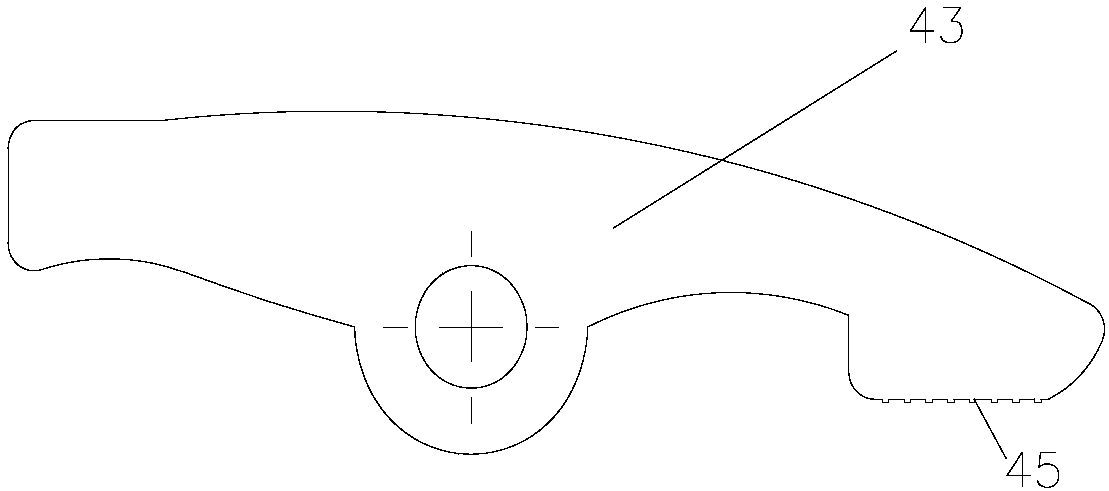

[0050] The traction mechanism includes a first motor and a rapier bracket fixed on the lifting device, a rigid rapier 3 is movably arranged on the rapier bracket, a first gear is arranged on the output shaft of the first motor, and the rigid rapier 3 A plurality of teeth are arranged on one side along its length direction to form a first rack, the first gear meshes with the first rack, and the first motor can drive the rigid rapier to reciprocate in the horizontal direction; the rapier bracket The end is provided with the first limit switch, a...

Embodiment 2

[0078] Flat multi-layer three-dimensional preforms (such as Figure 7 , 8 ) as an example, the multi-layer three-dimensional preform is designed to have a length of 500 mm, a width of 200 mm, and a thickness of 30 mm. It adopts a shallow cross-bend weaving structure, and the warp and weft yarns are designed to be T800 carbon fiber. The warp yarn specification is 24K×1 strand, and the density is 9 threads / cm; the weft yarn design has 6 specifications: specification 1 is 12K×1 strand, specification 2 is 12K× 2 strands, specification 3 is 12K×3 strands, specification 4 is 24K×1 strands, specification 5 is 24K×2 strands, specification 6 is 48K×1 strands, the total thickness of the weft yarn is 30 layers, and weft yarns of 6 specifications are staggered. The inter-layer distribution of specification weft yarns is shown in Table 1, and only three specifications of yarns need to be installed on the yarn storage device, and the yarn specifications on each yarn package are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com