Normal reinforced 2.5D fabric and weaving method thereof

A technology of fabrics and weaves, which is applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve problems such as instability and damage, and poor meridional compressive performance of composite materials, so as to enhance integrity, improve meridional compressive performance, Reduce the effect of compression instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The warp yarn is 190tex quartz fiber × 3 strands, the weft yarn is 190tex quartz fiber × 6 strands, the normal yarn is 190tex quartz fiber × 1 strand, the number of warp yarn layers is 6 layers, the warp density of the fabric is 90 pieces / 10 cm, and the weft density is 20 root / 10cm, the fabric width is 100cm, and the fabric structure is a layer-by-layer corner interlocking structure with normal reinforcement.

[0048] Warp and weft yarn process parameter design:

[0049] (1), the number of warp rows N=fabric width×warp density=100×90÷10=900 rows;

[0050] (2), number of warp yarn layers M=6 layers, number of weft yarn layers=M+1=7 layers;

[0051] Specific implementation steps:

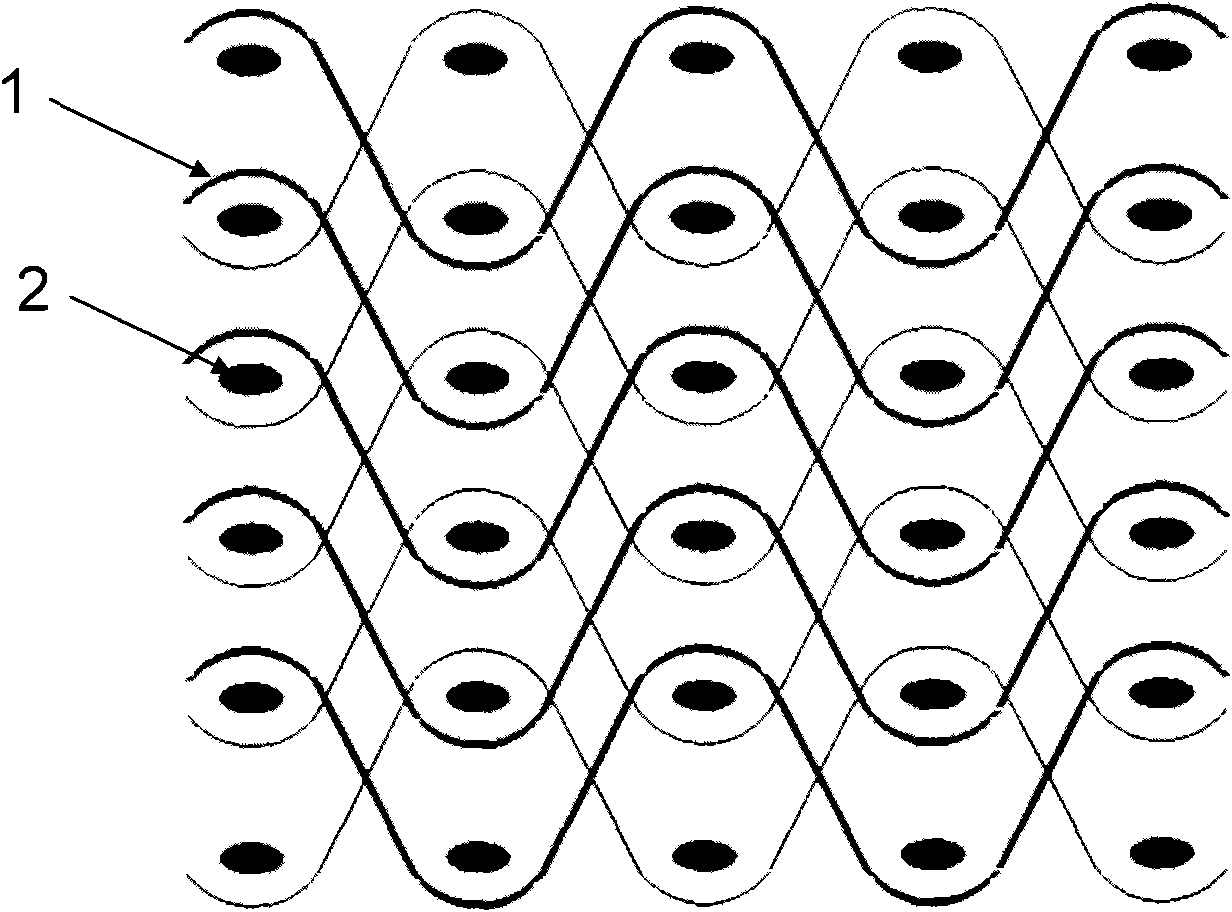

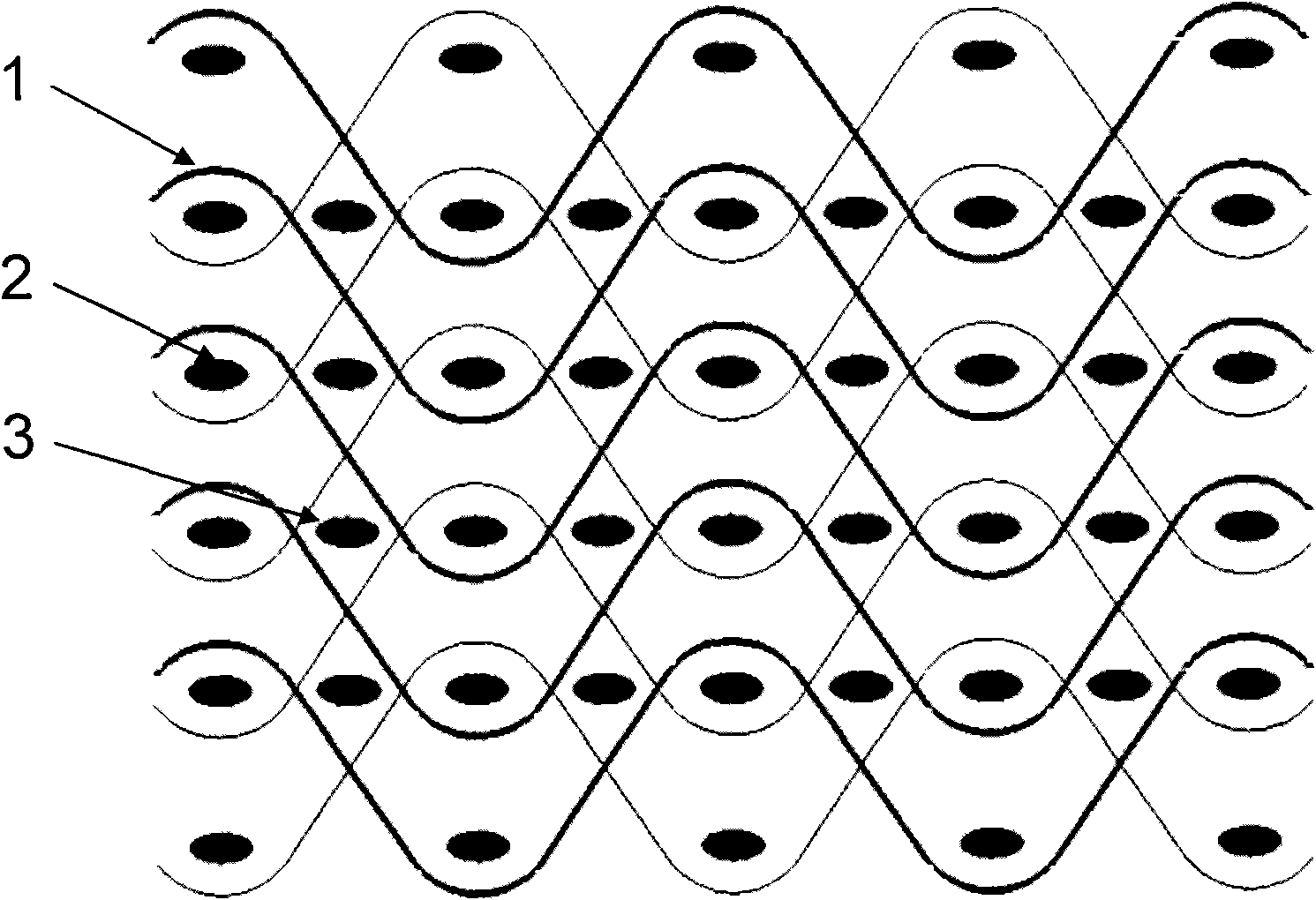

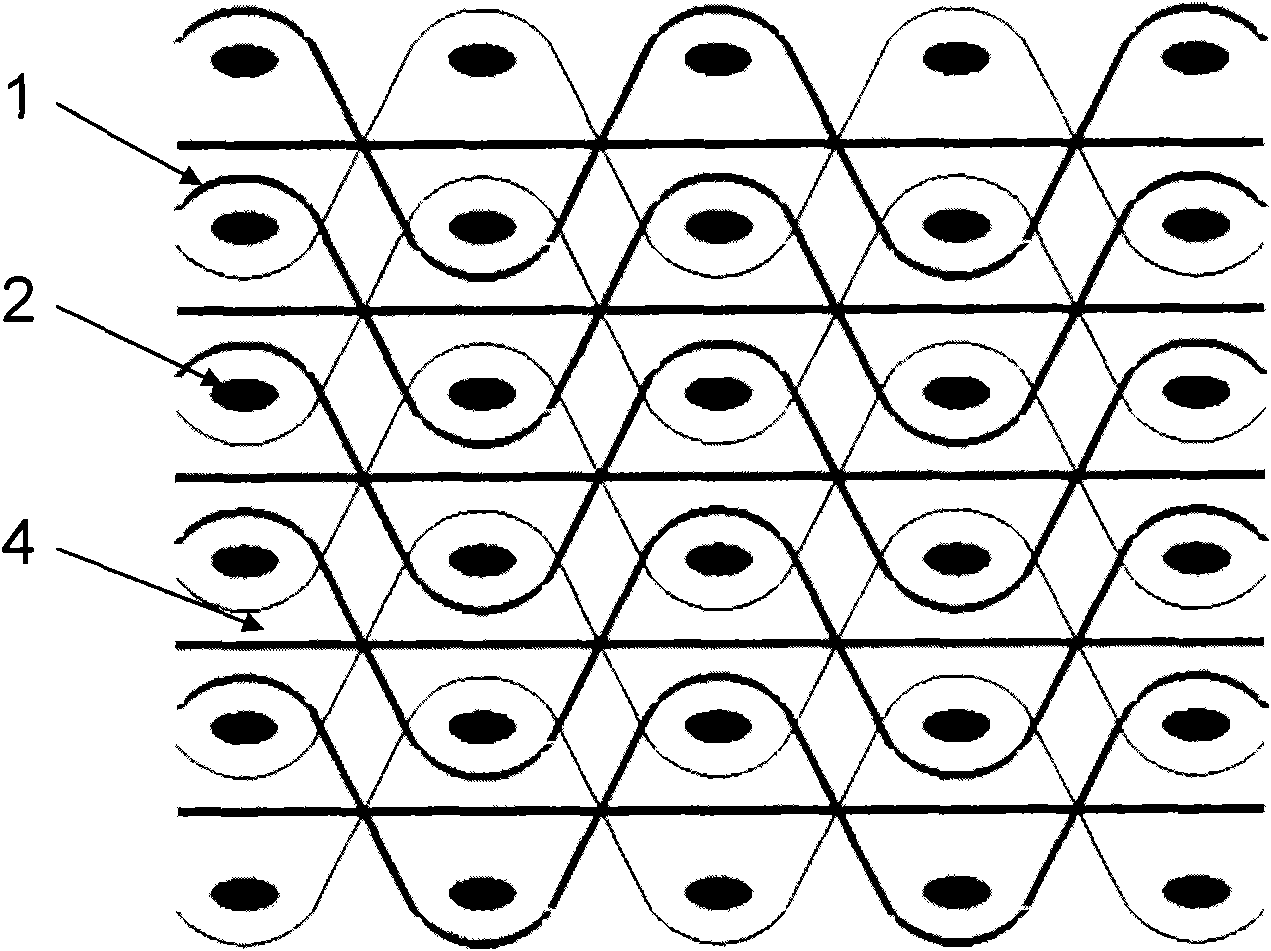

[0052] 1. Initial yarn arrangement. The warp yarns are arranged in 6 layers and 900 columns. For the sake of simplicity, 6 layers and 6 columns are selected for illustration (see Figure 5 , ○ represents the warp yarns in the odd-numbered columns, ● represents the warp yarns in the even-num...

Embodiment 2

[0060] The warp yarn is 190tex quartz fiber × 4 strands, the weft yarn is 190tex quartz fiber × 5 strands, the normal yarn is 190tex quartz fiber × 5 strands, the number of warp yarn layers is 6 layers, the warp density of the fabric is 57 pieces / 10cm, and the weft density is 40 root / 10cm, the fabric width is 100cm, and the fabric structure is a layer-by-layer corner interlocking structure with normal reinforcement.

[0061] Warp and weft yarn process parameter design:

[0062] 1. Number of warp rows N=fabric width×warp density=100×57÷10=570 rows.

[0063] 2, the number of warp yarn layers M=6 layers, the number of weft yarn layers=M+1=7 layers.

[0064] Specific implementation steps:

[0065] 1. Initial yarn arrangement. The warp yarns are arranged in 6 layers and 570 columns, and 6 layers and 6 columns are selected for illustration (see Figure 5 , ○ represents the warp yarns in the odd-numbered columns, ● represents the warp yarns in the even-numbered columns, and these...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com