Asynchronous alternate push type mine organzine and warp protective screen weave machine

A push-type, protective net technology, applied in online nets, applications, home appliances, etc., can solve problems such as high cost and difficult to guarantee product quality, and achieve the effects of reducing production costs, improving weaving efficiency, reducing labor intensity and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described with reference to the accompanying drawings.

[0024] In the present invention, the moving direction of wire mesh conveying is defined as the rear of each mechanism, and the reverse direction of wire mesh conveying is defined as the front of each mechanism.

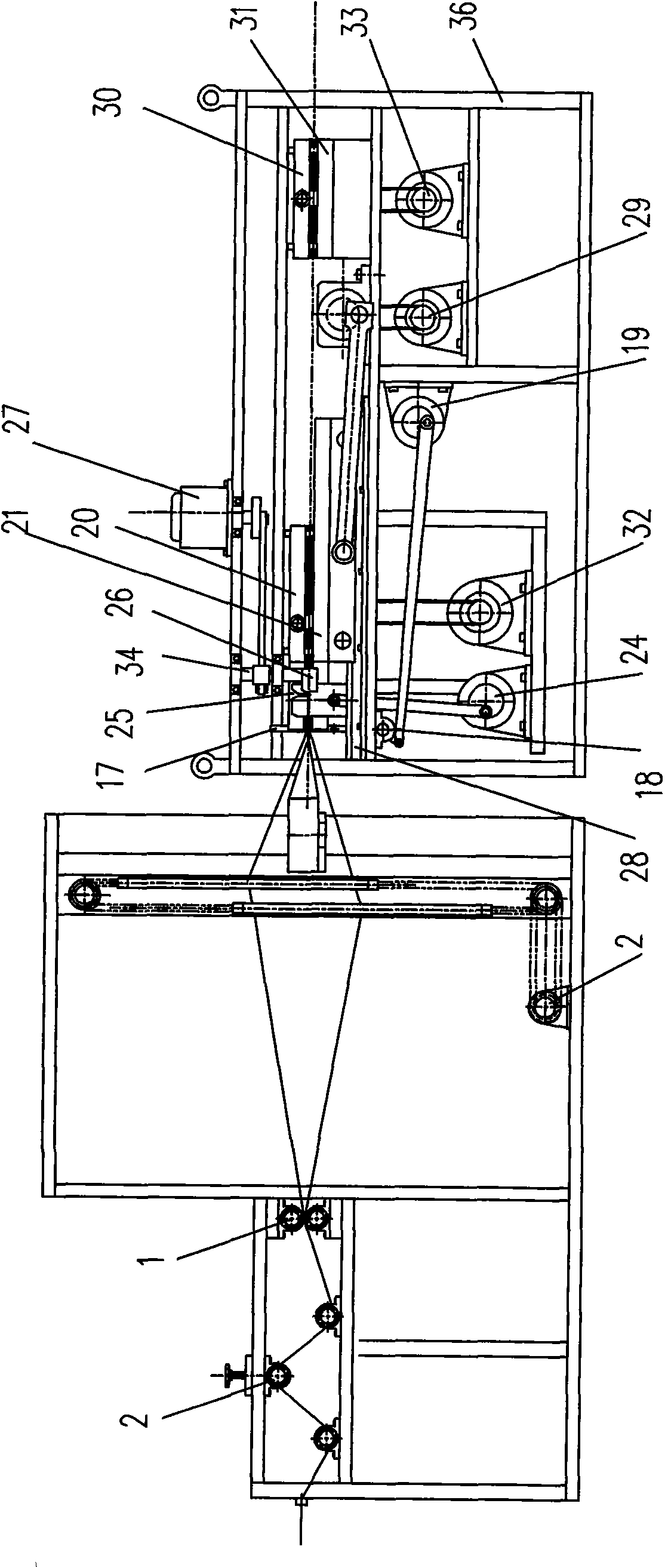

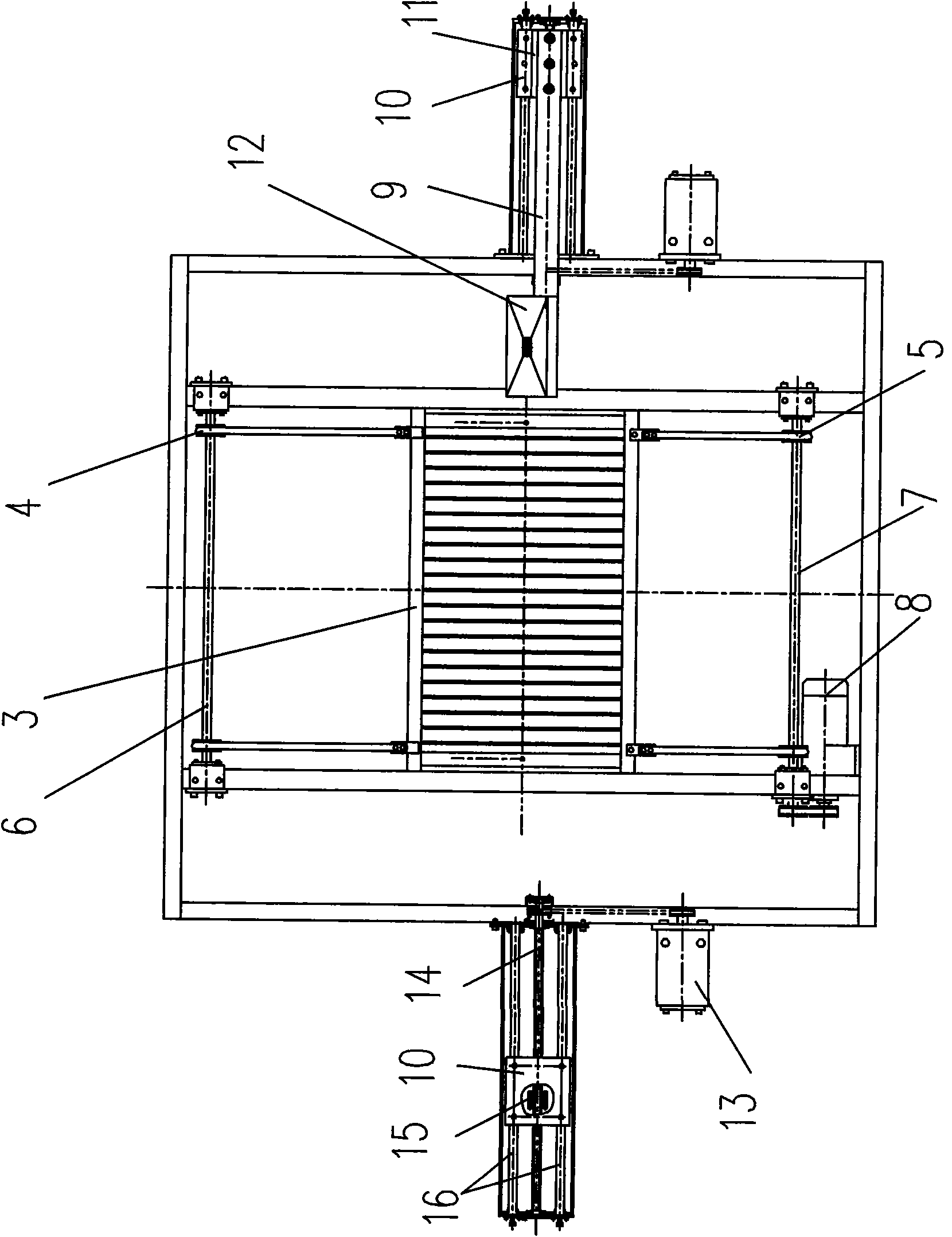

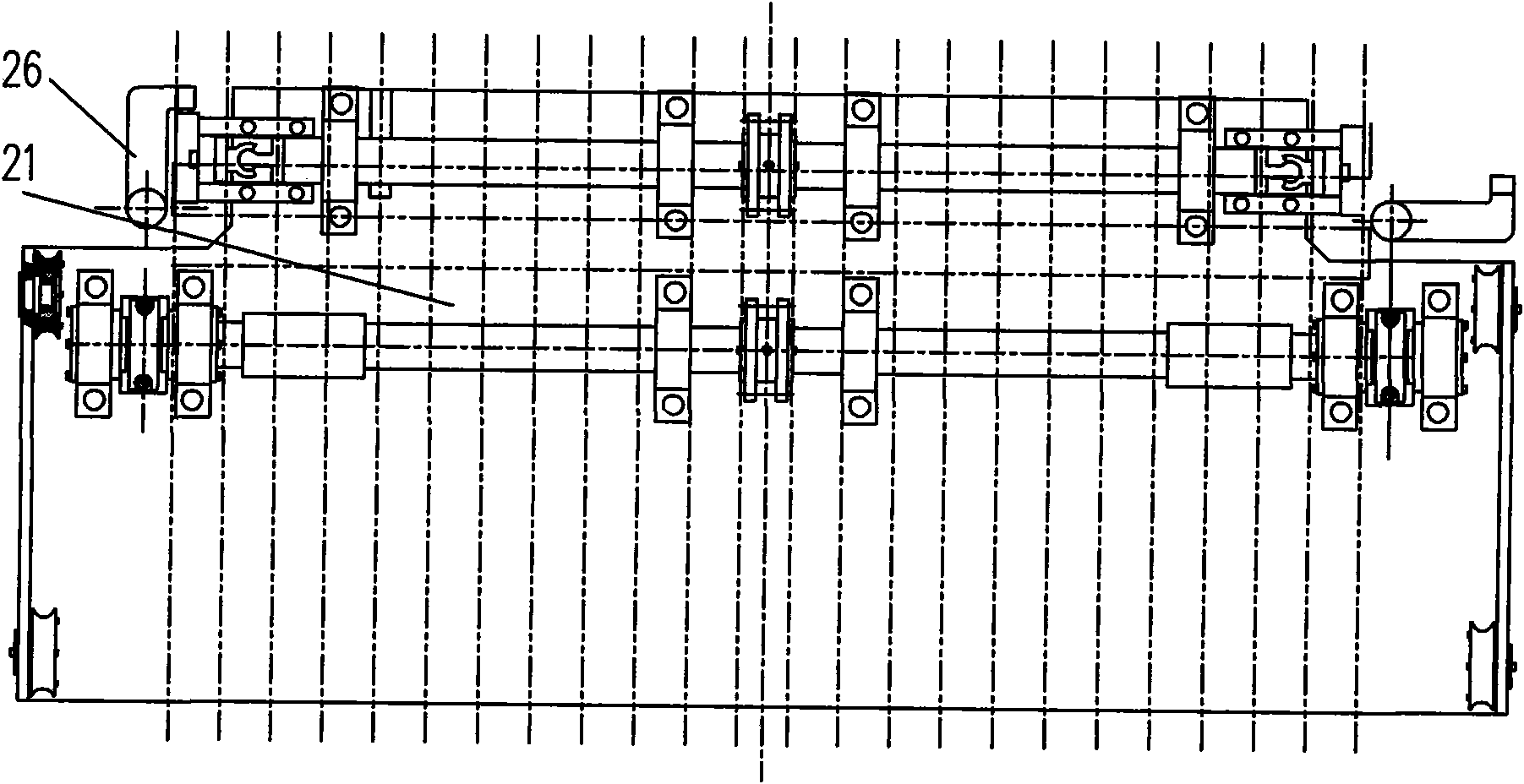

[0025] The structure of the present invention is as follows: an asynchronous alternate-propulsion type mine warp and weft protective net weaving machine, including a warp wire guide transmission mechanism, a warp wire up and down turning mechanism, a weaving mechanism, a forming mechanism, and a shaping mechanism arranged in sequence along the warp direction, and each mechanism includes rack 36;

[0026] - The guide transmission mechanism includes a guide wheel 1 and an adjustable tension wheel 2 .

[0027] ——The warp wire up and down turning mechanism includes two grid plates 3 that can reciprocate up and down staggered; The top and bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com