Novel numerical control reed-moving fluff conjugate cam beating-up mechanism

A technology of conjugate cam and reed movement, which is applied in looms, textiles, textiles and papermaking, and can solve the problems of low-efficiency yarn requirements and high energy consumption of weft insertion integrated machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

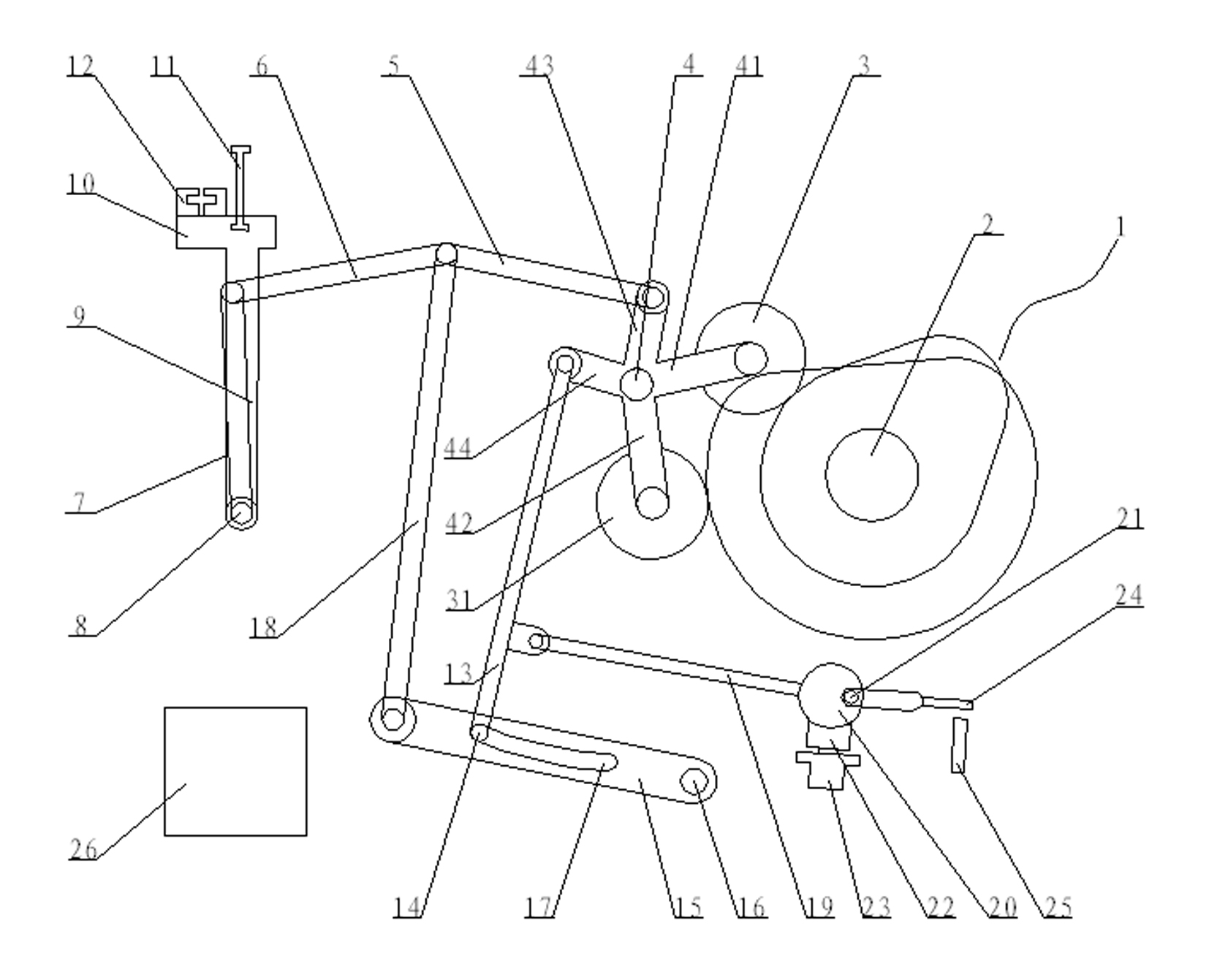

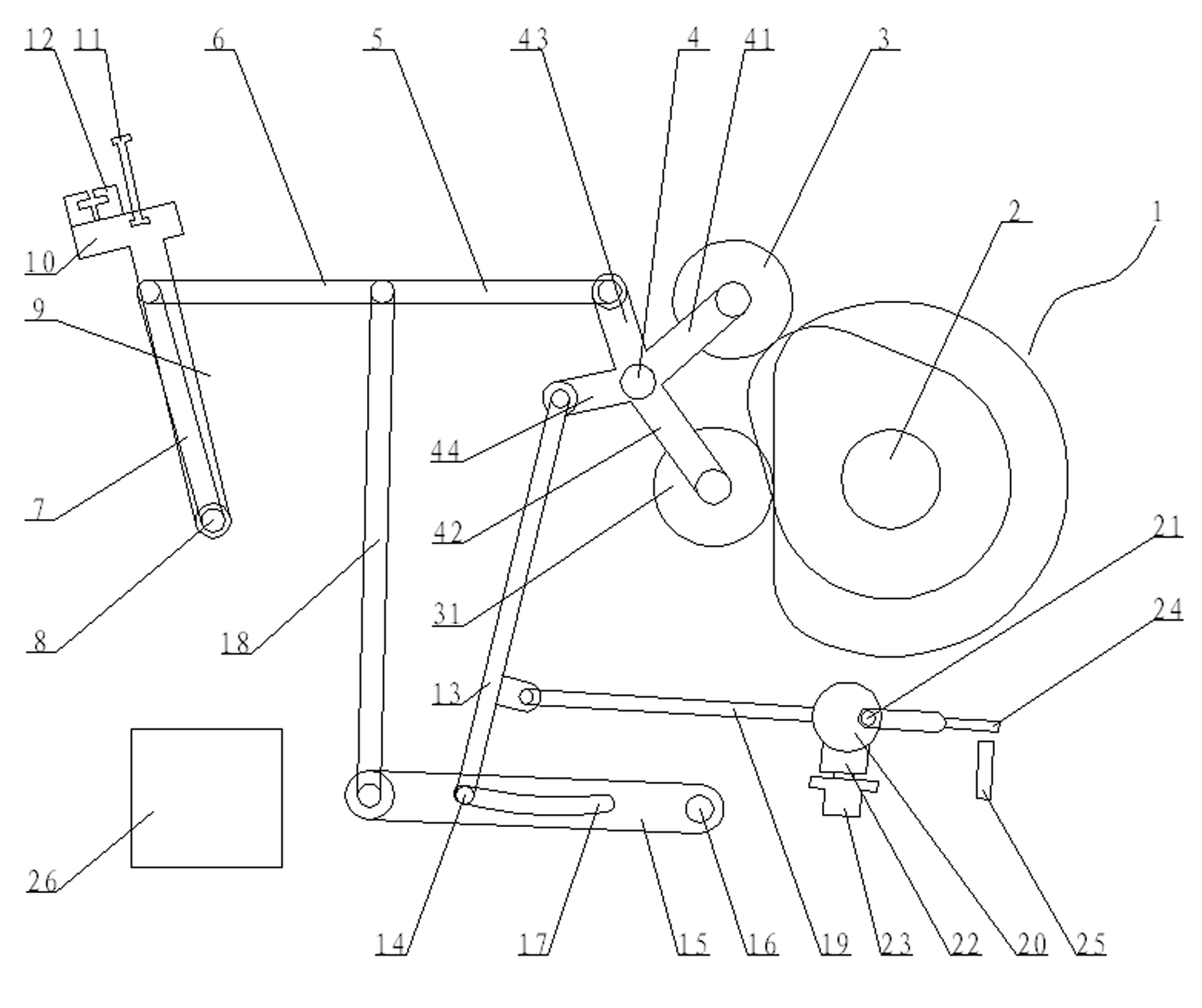

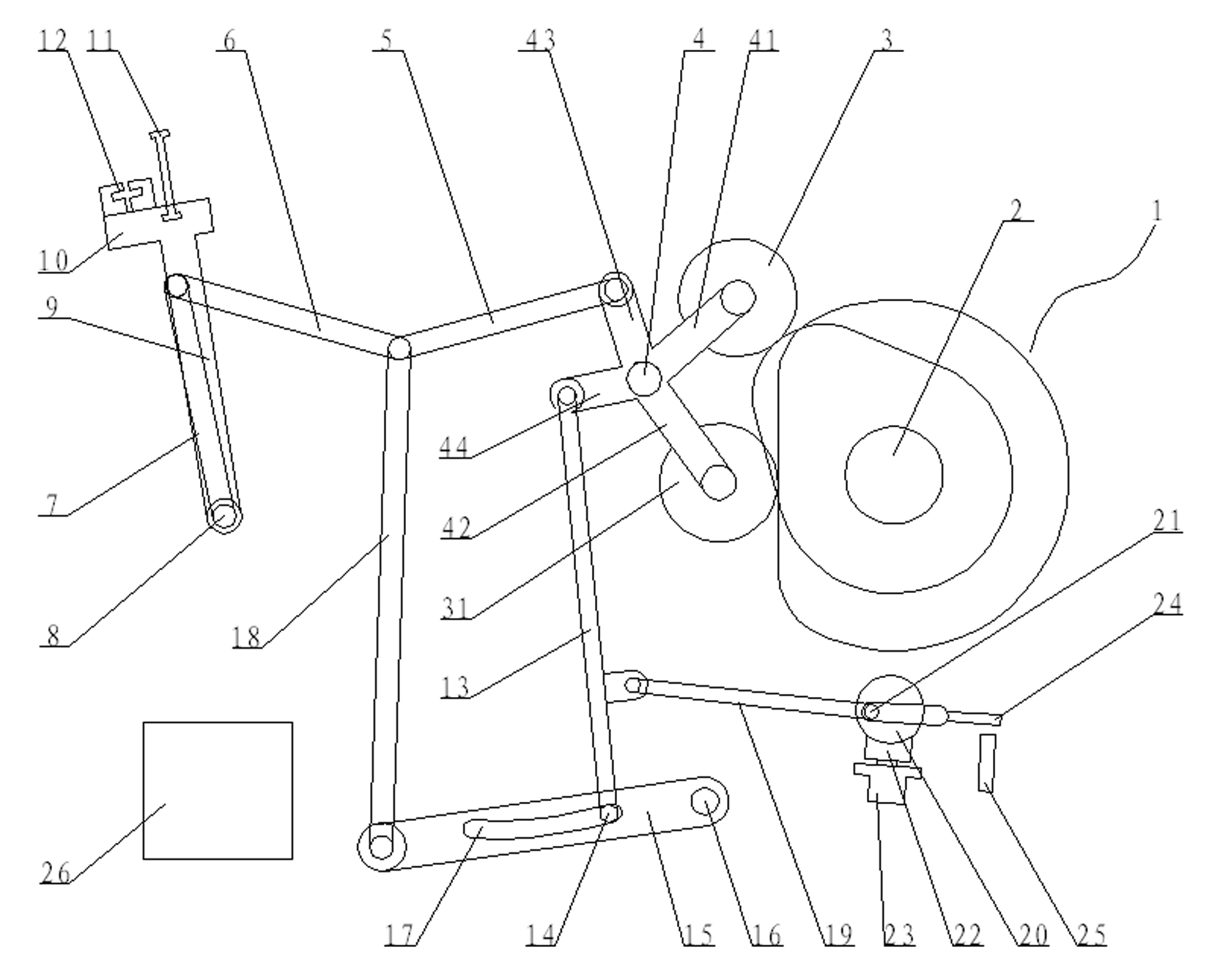

[0017] Figure 1-3 As shown, the new numerically controlled reed-moving fluffing conjugate cam beating-up mechanism includes a conjugate cam group 1, a main shaft 2, an upper rotor 3, a lower rotor 31, a swing shaft 4, an upper rotor swing arm 41, a lower rotor swing arm 42, a beating-up Drive swing arm 43, positioning swing arm 44, primary drive link 5, secondary drive link 6, beat-up swing arm 7, beat-up shaft 8, sley foot 9, sley 10, steel reed 11, guide rail piece 12. Adjusting link 13, positioning rotor 14, slotted swing arm 15, slotted swing arm shaft 16, arc groove 17, positioning link 18, eccentric link 19, eccentric cam 20, eccentric shaft 21, speed reduction mechanism 22 , CNC motor 23, origin signal 24, signal acquisition mechanism 25 and electric control box 26. Main shaft 2, pendulum shaft 4, beating shaft 8, grooved swing arm shaft 16, and eccentric shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com