Broad-width carbon-fiber knitting machine and method for producing carbon-fiber gridding cloth by using same

A weaving machine and carbon fiber technology, which is applied in looms, fabrics, textiles, etc., can solve problems such as reduction, and achieve the effect of improving weaving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

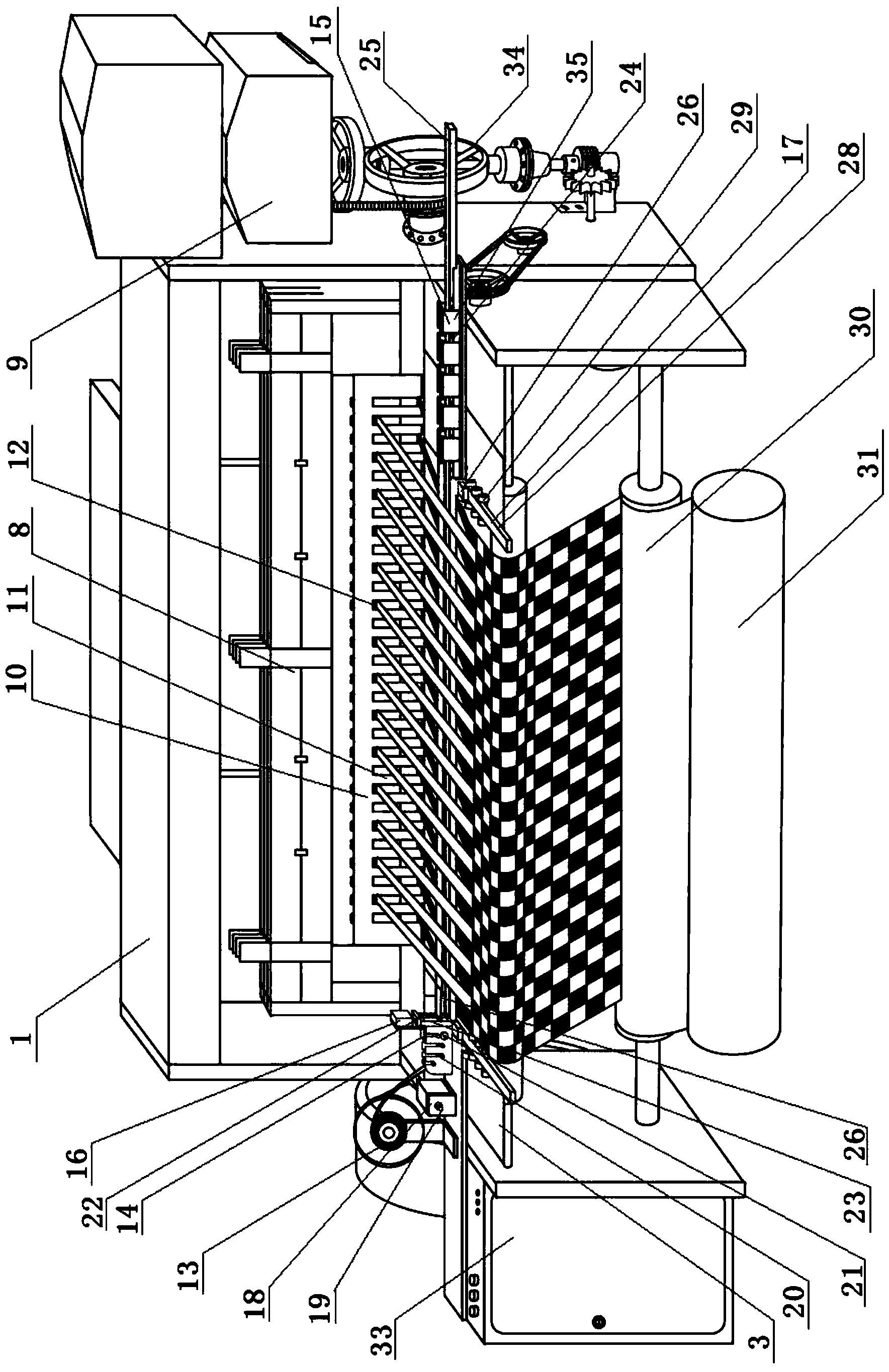

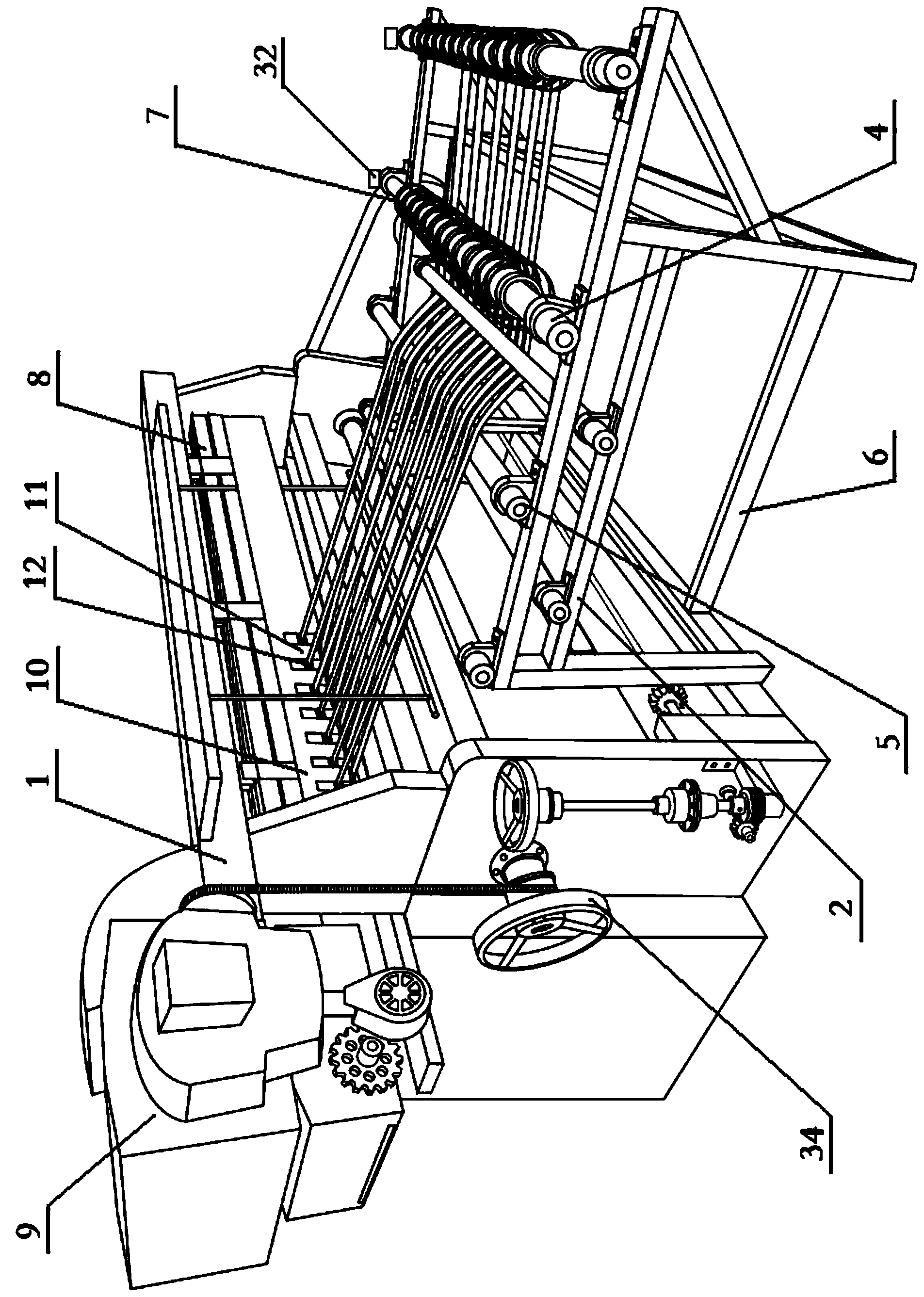

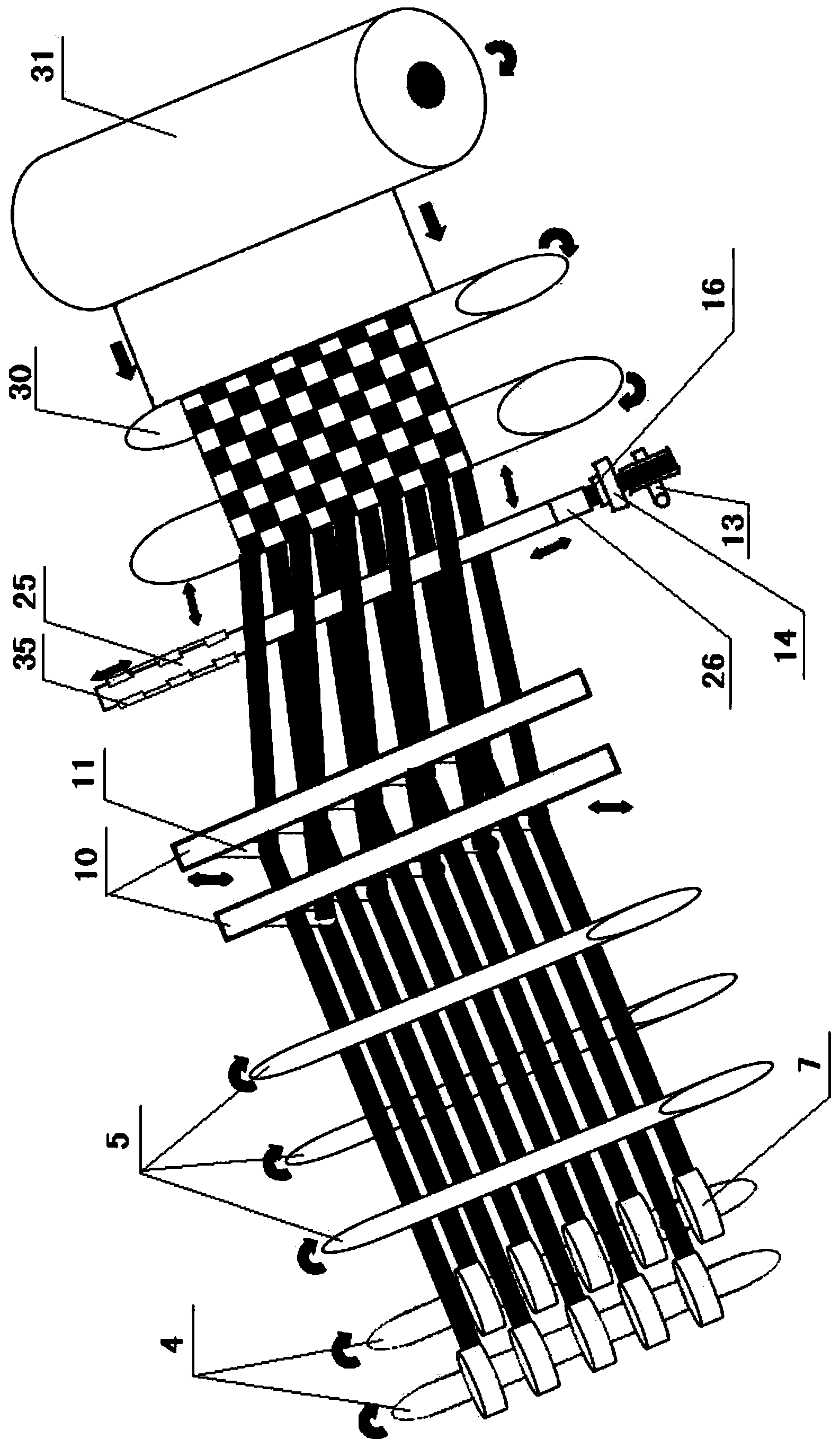

[0062] Embodiment: The device weaves 12K carbon fiber tow with a width of 20 mm, and the number of revolutions is 5 to 40 revolutions per minute.

[0063] The width of the carbon fiber fabric that can be produced by this device can reach up to 1000mm, and the running speed of the weaving machine can reach 120 rpm. The computer control system of this device all uses a touch control panel. The width of the carbon fiber that can be used for weaving is: 5mm to 50mm. The design of the weaving machine effectively prevents the deformation of the fiber width during the weaving process. Fabrics can be woven using a variety of weave constructions including plain weave, twill weave, and satin weave.

[0064]The knitting machine of the present invention can effectively improve the weaving efficiency of the grid cloth of the carbon fiber tow belt after fiber expansion, solve the problem that the weaving of the carbon fiber tow belt after fiber expansion needs to be purely handmade, and sav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com