Mixed polyester resin and preparation method and powder coating thereof

A polyester resin and powder coating technology, applied in polyester coatings, powder coatings, coatings, etc., can solve the problems of poor coating film performance and darker resin color, and achieve stable gloss, clear and full surface, and smooth flow flat excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

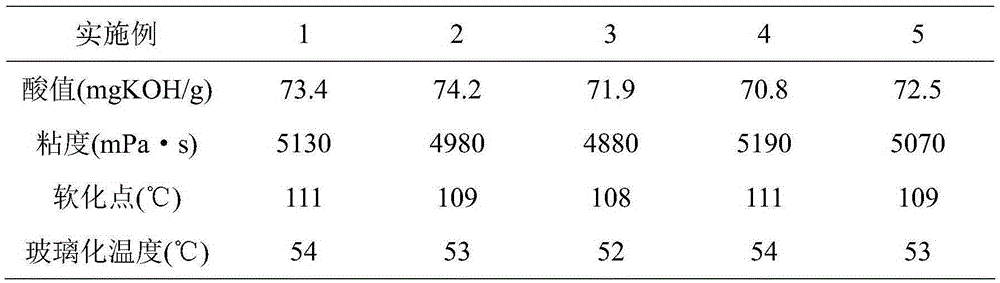

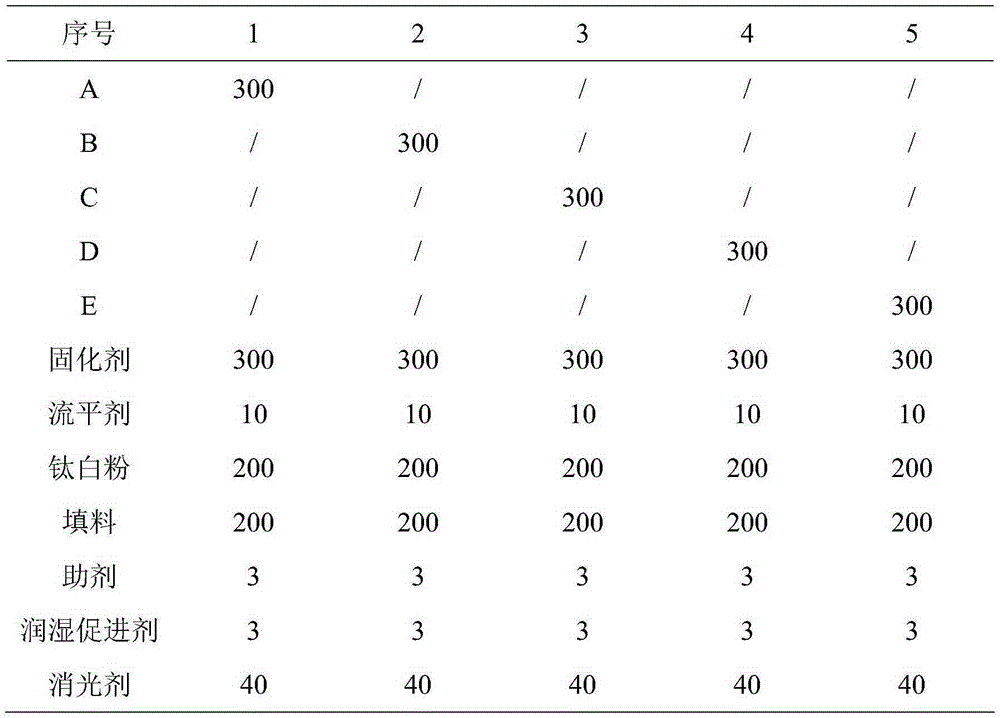

Examples

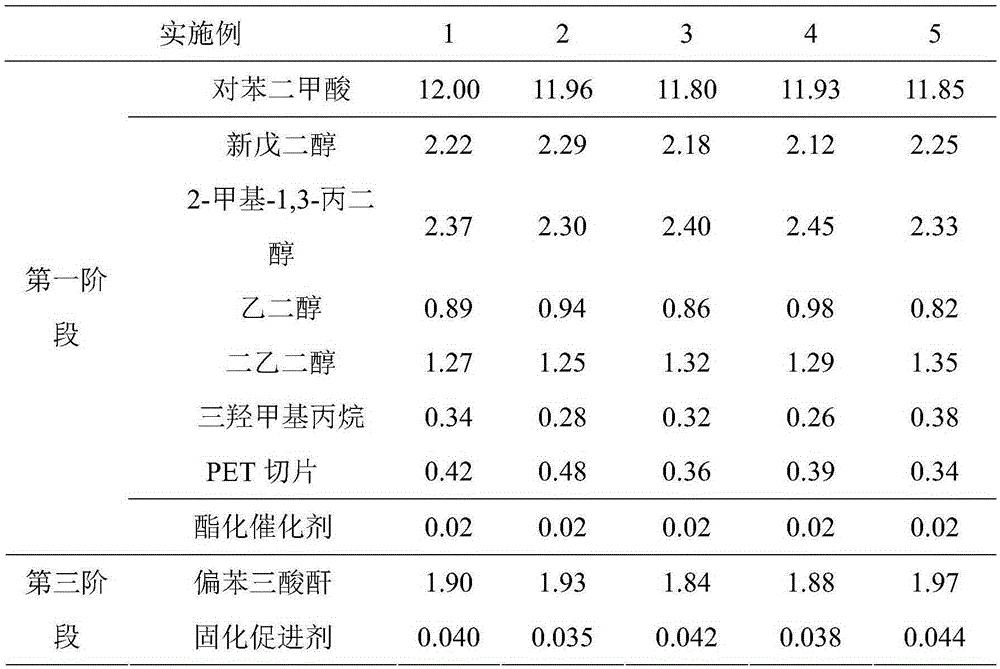

Embodiment 1

[0025] (1) The first stage: raise the temperature of the reactor to 85°C, start the stirring, and put in the formula amount of alcohol, acid, PET chip and esterification catalyst in sequence, close the reactor after feeding, slowly raise the temperature to 245°C, and maintain the reaction When the temperature at the top of the reaction kettle drops below 60°C, the acid value is 18 mgKOH / g by sampling;

[0026] (2) The second stage: reduce the temperature of the kettle to 230°C, continue the reaction for 1.5h under the vacuum degree of -0.098MPa, and take a sample to detect the acid value of 9mgKOH / g;

[0027] (3) The third stage: first lower the temperature of the kettle to 210°C and put in trimellitic anhydride, continue the reaction for 100 minutes, then lower the temperature to 190°C and put in the curing accelerator, continue to react for 30 minutes, and take samples to test the acid value and viscosity.

Embodiment 2

[0029] (1) The first stage: raise the temperature of the reactor to 90°C, start stirring, and put in the alcohol, acid, PET chip and esterification catalyst in the formula, close the reactor after feeding, slowly raise the temperature to 246°C, and maintain the reaction When the temperature at the top of the reaction kettle drops below 60°C, the acid value is 17 mgKOH / g by sampling;

[0030] (2) The second stage: lower the temperature of the kettle to 232°C, continue the reaction for 1.3h under the vacuum degree of -0.097MPa, and take a sample to detect the acid value and the acid value is 10mgKOH / g;

[0031] (3) The third stage: first lower the temperature of the kettle to 215°C and put in trimellitic anhydride, continue the reaction for 90 minutes, then lower the temperature to 195°C and put in the curing accelerator, continue to react for 25 minutes, and take samples to test the acid value and viscosity.

Embodiment 3

[0033] (1) The first stage: raise the temperature of the reactor to 90°C, start the stirring, and put in the formula amount of alcohol, acid, PET chip and esterification catalyst in sequence, close the reactor after feeding, slowly raise the temperature to 247°C, and maintain the reaction When the temperature at the top of the reaction kettle drops below 60°C, the acid value is 19 mgKOH / g by sampling;

[0034] (2) The second stage: reduce the temperature of the kettle to 233°C, continue the reaction for 1.2h under the vacuum degree of -0.096MPa, and take a sample to detect the acid value of 10mgKOH / g;

[0035] (3) The third stage: first lower the temperature of the kettle to 220°C and put in trimellitic anhydride, continue the reaction for 80 minutes, then lower the temperature to 200°C and put in the curing accelerator, continue to react for 27 minutes, and take samples to test the acid value and viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com