Easy-toning single-coating elastic coating and preparation method thereof

An elastic coating and single-coating technology, applied to polyester coatings, coatings, etc., can solve problems such as difficult control, time-consuming and labor-intensive, and variable film feel and gloss, so as to increase applicability, save costs, and improve The effect of toning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

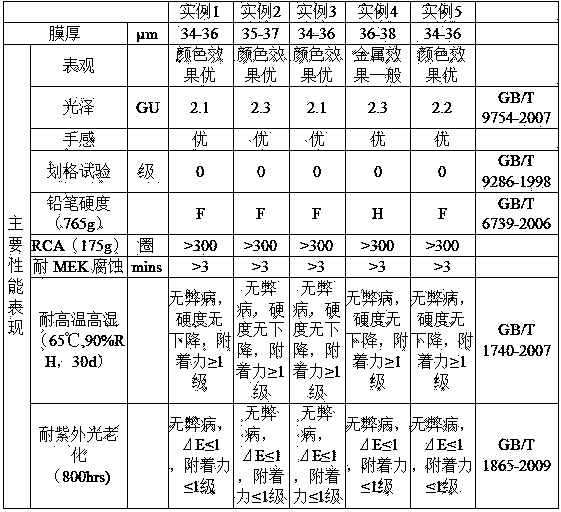

Examples

preparation example Construction

[0029] A kind of preparation method of easy-to-color single coating elastic paint, comprises the following steps:

[0030] Preparation of the base material: put 20-30 parts of polyester polyol and a part of diluent into the dispersion tank, stir evenly at a speed of 400-500RPM; then put in 20-30 parts of hydroxy acrylic resin, stir evenly; increase the stirring speed At 600-700RPM, put in 1-2 parts of leveling agent, 1-3 parts of hand feeling aid, 1-2 parts of UV absorber, 0.5-2 parts of drier, 5-10 parts of acetic acid butyric acid Cellulose, last for 10-15min; then add 4-8 parts of nano fumed silica, increase the stirring speed to 800-1000RPM, and continue stirring until the fineness is ≤20μm, and the gloss deviation of the black background is ≤0.1GU; put in 1-2 part diluent to adjust the viscosity, and finally use a 100μm filter bag to filter and let it stand for one day to defoam and set aside;

[0031]Preparation of color paste: put 10-20 parts of polyester polyol and a ...

Embodiment 1

[0042] A kind of preparation method of easy-to-color single coating elastic paint, comprises the following steps:

[0043] Preparation of base material: put 20 parts of polyester polyol (hydroxyl value 56mgKOH / g) and 20 parts of diluent into the dispersion tank, and stir evenly at a speed of 400RPM; then put in 20 parts of hydroxyl acrylic resin, and stir evenly ; Increase the stirring speed to 600RPM, put in 1 part of BYK-333 leveling agent, 1 part of hand feeling aid AcureDMV, 1 part of UV absorber UV-292, 0.5 part of organotin drier, 5 parts of acetic acid Cellulose butyrate, continue to stir for 10 minutes; then add 4 parts of nano fumed silica, increase the stirring speed to 800RPM, and continue to stir until the fineness is ≤20μm, and the gloss deviation of the black background is ≤0.1GU; add 1 part of diluent to Adjust the viscosity, and finally use a 100μm filter bag to filter, and let it stand for a day to defoam and set aside;

[0044] Preparation of black slurry: p...

Embodiment 2

[0050] A kind of preparation method of easy-to-color single coating elastic paint, comprises the following steps:

[0051] Preparation of base material: Put 25 parts of polyester polyol (hydroxyl value 56mgKOH / g) and 25 parts of diluent into the dispersion tank, stir evenly at a speed of 400RPM; then put in 23 parts of hydroxyl acrylic resin, stir evenly ; Increase the stirring speed to 600RPM, put in 1.5 parts of BYK-333 leveling agent, 2 parts of hand feeling aid AcureDMV, 1.5 parts of UV absorber UV-292, 1.2 parts of organotin drier, 8 parts of acetic acid Cellulose butyrate, continue to stir for 10 minutes; then add 5 parts of nano fumed silica, increase the stirring speed to 1000RPM, and continue to stir until the fineness is ≤20μm, and the gloss deviation of the black background is ≤0.1GU; add 1 part of diluent to Adjust the viscosity, and finally use a 100μm filter bag to filter, and let it stand for a day to defoam and set aside;

[0052] Preparation of white slurry: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com