Multicolor low-gloss water-based paint primer-finish composition for passenger train

A technology for railway passenger cars and water-based coatings, used in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc. The effect of reducing the content of volatile organic compounds, stabilizing the gloss of the paint film, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

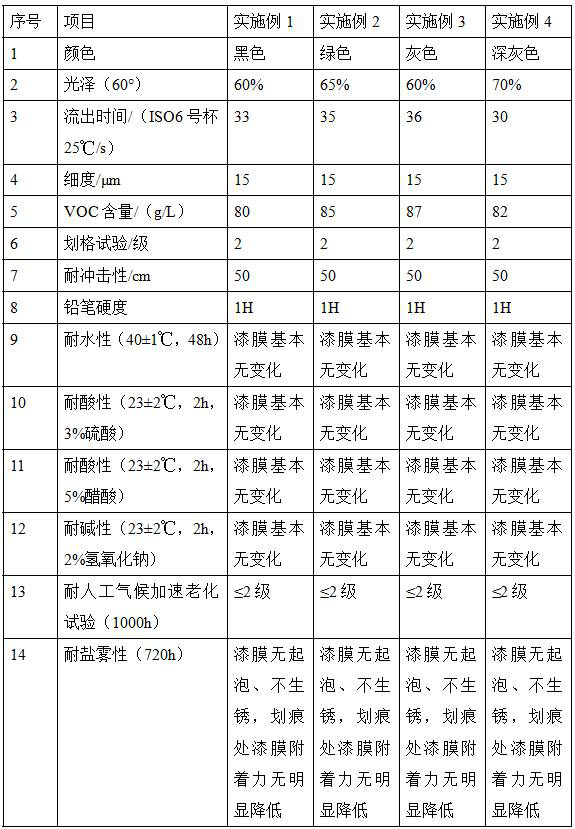

Examples

Embodiment 1

[0052] To prepare water-based acrylic polyurethane component A, feed 100 kg in total, and add 12.64 kg of deionized and 11 kg of hydroxyl-containing water-based acrylic resin sk6480, 0.05 kg of defoamer Foamex8030, 0.1kg of dispersant Zeta Sperse 3100, 3.0kg of wetting agent TRITON X-405, after adding, stir for 10min to mix evenly, slowly add 0.1kg of rheology additive RM-8W, increase the speed to 600r / min and stir for 15min, then add 3.5kg of rutile titanium dioxide, 2kg of carbon black, and then increase the speed to 800r / min for high-speed dispersion and stirring for 20 minutes to obtain a pre-dispersed slurry; use a sand mill to grind the pre-dispersed slurry to a fineness of less than 15 μm to obtain a finely ground slurry; Stir the ground slurry at 600r / min, add 44kg hydroxyl-containing water-based acrylic resin sk6480, 15kg self-dulling water-based polyurethane resin PU-210, 0.05kg defoamer Foamex8030, 5kg co-solvent, 0.2kg leveling agent HY5030, 3. 16kg of deionized wa...

Embodiment 2

[0057] To prepare water-based acrylic polyurethane component A, feed 100 kg in total, and add 8.96 kg of deionized and 12 kg of hydroxyl-containing water-based acrylic resin GS359, 0.1 kg of defoamer Foamex3062, 0.2kg of dispersant Tego Dispers 755W, 2.5kg of wetting agent TRITON X-405, after adding, stir for 12min to mix evenly, slowly add 0.2kg of rheology additive RM-12W, increase the speed to 700r / min and stir for 15min, then add 5kg of rutile titanium dioxide, then increase the rotating speed to 900r / min for high-speed dispersion and stirring for 25 minutes to obtain a pre-dispersed slurry; use a sand mill to grind the pre-dispersed slurry to a fineness of less than 15 μm to obtain a finely ground slurry; Under stirring at 700r / min, add 48kg hydroxyl-containing water-based acrylic resin GS359, 10kg self-dulling water-based polyurethane resin A-20802, 0.1kg defoamer Foamex3062, 4kg co-solvent, 0.4kg leveling agent HY5030, 2.24kg deionized water , Stir for 13 minutes after ...

Embodiment 3

[0062] To prepare water-based acrylic polyurethane component A, feed 100 kg in total, and add 9.04 kg of deionized, 12 kg of hydroxyl-containing water-based acrylic resin sk6480, 0.15 kg of defoamer Foamex8030, 0.3kg dispersant PX4585, 3.0kg wetting agent TRITON X-405, after adding, stir for 15min to mix evenly, slowly add 0.2kg rheological additive SCT-275, increase the speed to 800r / min and stir for 20min, then add 9kg rutile Type titanium dioxide, 1kg carbon black, and then increase the rotating speed to 1000r / min high-speed dispersion and stirring for 30 minutes to obtain a pre-dispersed slurry; use a sand mill to grind the pre-dispersed slurry to a fineness of less than 15 μm to obtain a finely ground slurry; Stir the slurry at 800r / min, add 48kg hydroxyl-containing water-based acrylic resin sk6480, 10kg self-dulling water-based polyurethane resin PU-210, 0.15kg defoamer Foamex8030, 4kg co-solvent, 0.4kg leveling agent HY5030, 2.26kg For ionized water, stir for 15 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com