Preparation method of corrosion-resistant and wear-resistant modified ceramic coating on aluminum alloy surface

A technology of aluminum alloy surface and ceramic coating, which is applied in the direction of metal material coating process, coating, heating inorganic powder coating, etc., can solve the problems of coating cracks and affecting coating bonding force, etc., to improve bonding force, Combines solid, well-performing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

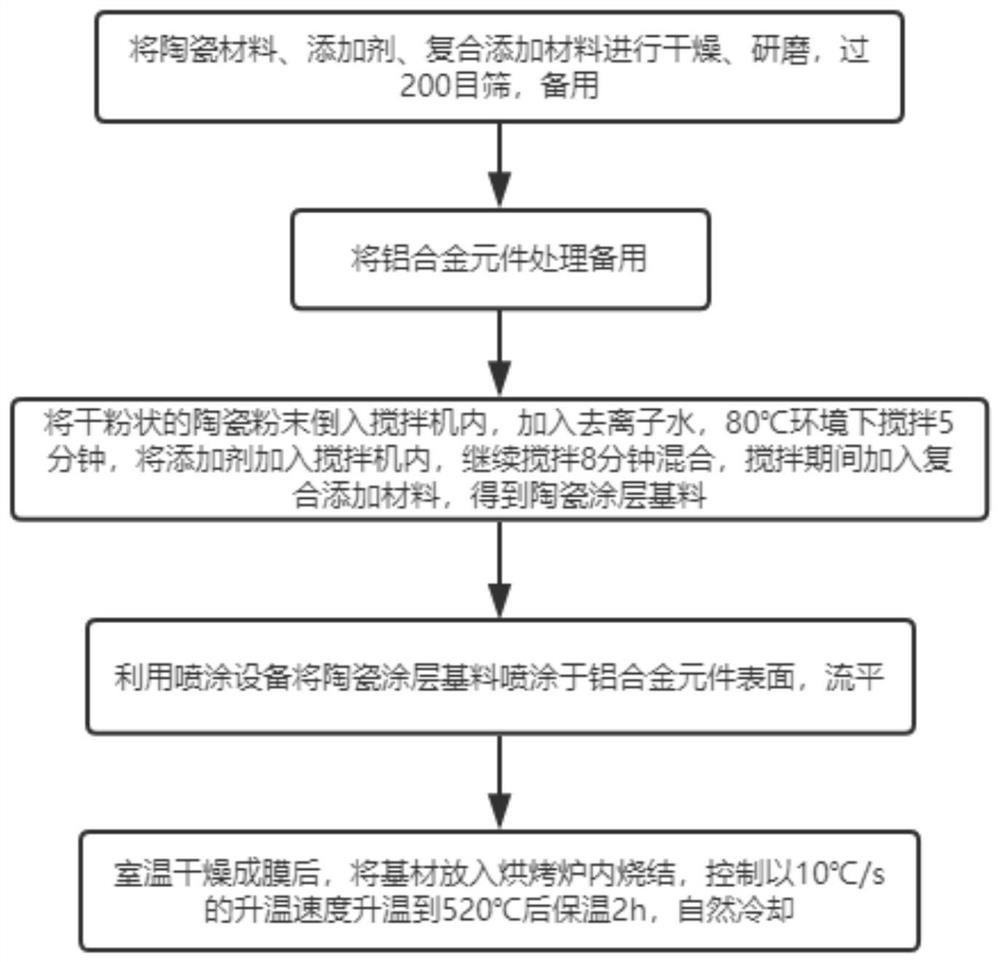

[0034] A method for preparing an anti-corrosion and wear-resistant modified ceramic coating on the surface of an aluminum alloy, such as figure 1 shown, including the following steps:

[0035] S1: Dry and grind ceramic materials, additives, and composite additives, pass through a 200-mesh sieve, and set aside;

[0036] S2: processing the aluminum alloy components for use;

[0037] S3: Pour the dry powdered ceramic powder into the blender, add deionized water, and stir for 5 minutes at 80°C, add the additives into the blender, and continue stirring for 8 minutes to mix, and add composite additives during the stirring to obtain a ceramic coating Binder;

[0038] S4: Use spraying equipment to spray the ceramic coating base material on the surface of the aluminum alloy component, leveling;

[0039] S5: After drying at room temperature to form a film, put the base material into a baking oven for sintering, control the heating rate to 520°C at a rate of 10°C / s, keep it warm for 2...

Embodiment 2

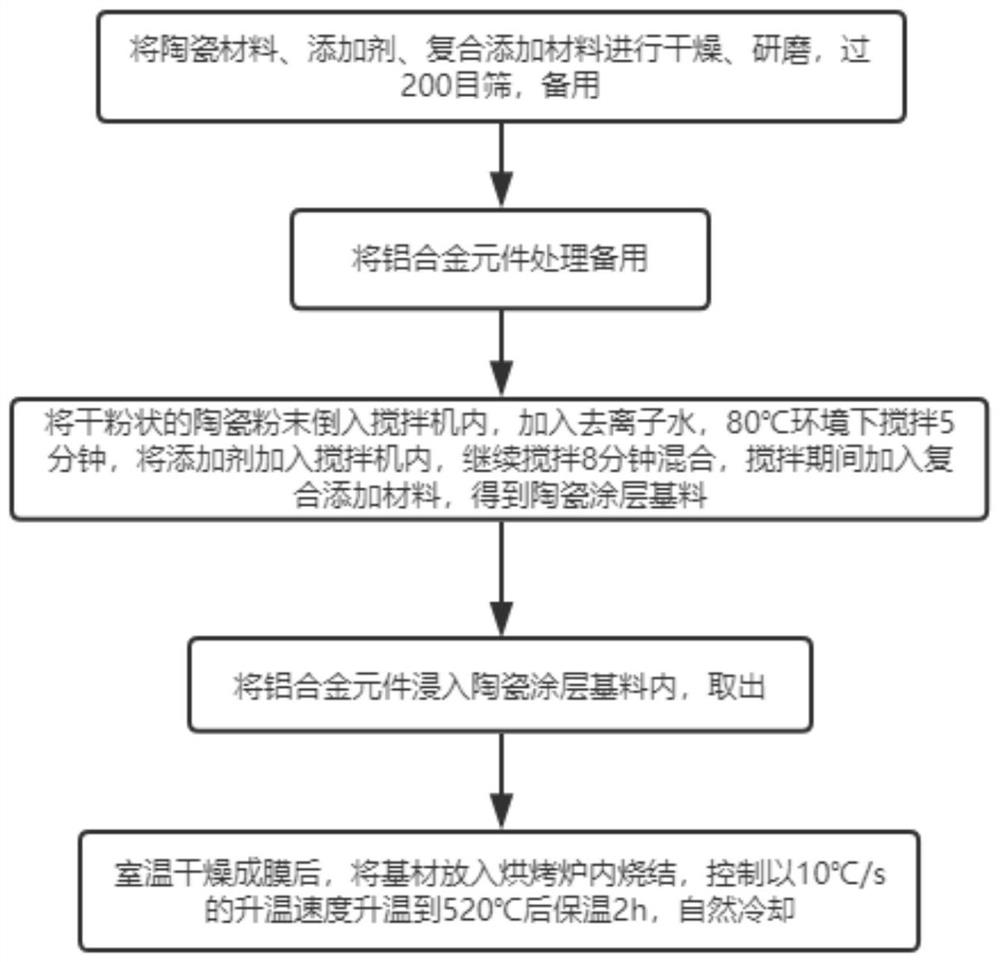

[0054] A method for preparing an anti-corrosion and wear-resistant modified ceramic coating on the surface of an aluminum alloy, such as figure 2 shown, including the following steps:

[0055] S1: Dry and grind ceramic materials, additives, and composite additives, pass through a 200-mesh sieve, and set aside;

[0056] S2: processing the aluminum alloy components for use;

[0057] S3: Pour the dry powdered ceramic powder into the blender, add deionized water, and stir for 5 minutes at 80°C, add the additives into the blender, and continue stirring for 8 minutes to mix, and add composite additives during the stirring to obtain a ceramic coating Binder;

[0058] S4: Dip the aluminum alloy element into the ceramic coating base material and take it out;

[0059] S5: After drying at room temperature to form a film, put the base material into a baking oven for sintering, control the heating rate to 520°C at a rate of 10°C / s, keep it warm for 2 hours, and cool naturally.

[0060...

Embodiment 3

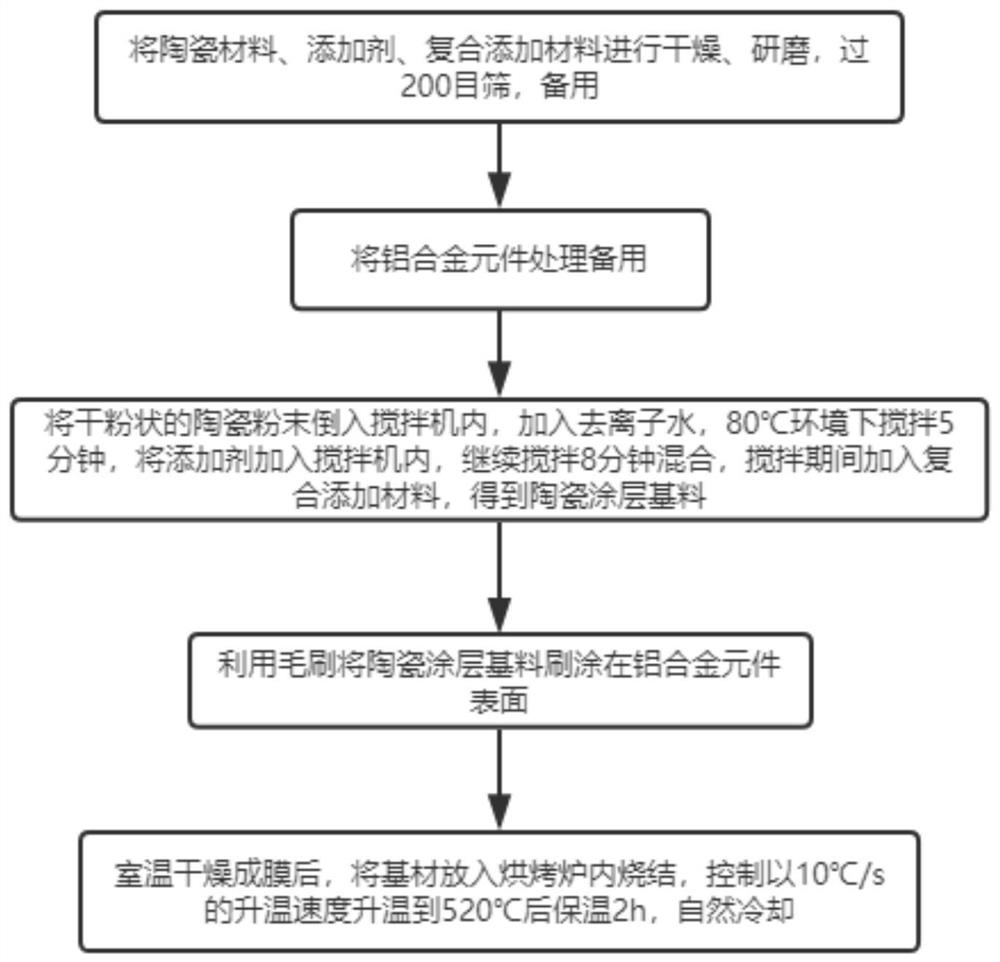

[0072] A method for preparing an anti-corrosion and wear-resistant modified ceramic coating on the surface of an aluminum alloy, such as image 3 shown, including the following steps:

[0073] S1: Dry and grind ceramic materials, additives, and composite additives, pass through a 200-mesh sieve, and set aside;

[0074] S2: processing the aluminum alloy components for use;

[0075] S3: Pour the dry powdered ceramic powder into the blender, add deionized water, and stir for 5 minutes at 80°C, add the additives into the blender, and continue stirring for 8 minutes to mix, and add composite additives during the stirring to obtain a ceramic coating Binder;

[0076] S4: Brushing the ceramic coating base material on the surface of the aluminum alloy element with a brush;

[0077] S5: After drying at room temperature to form a film, put the base material into a baking oven for sintering, control the heating rate to 520°C at a rate of 10°C / s, keep it warm for 2 hours, and cool natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com