Flatting modification technology of edge band surface UV curable varnish

A technology of edge banding and varnish, which is applied in the direction of coating, epoxy resin coating, polyester coating, etc., can solve the problems of unstable gloss, wear resistance, low hardness, etc., to avoid the effect of oxygen inhibition, Effect of improving quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

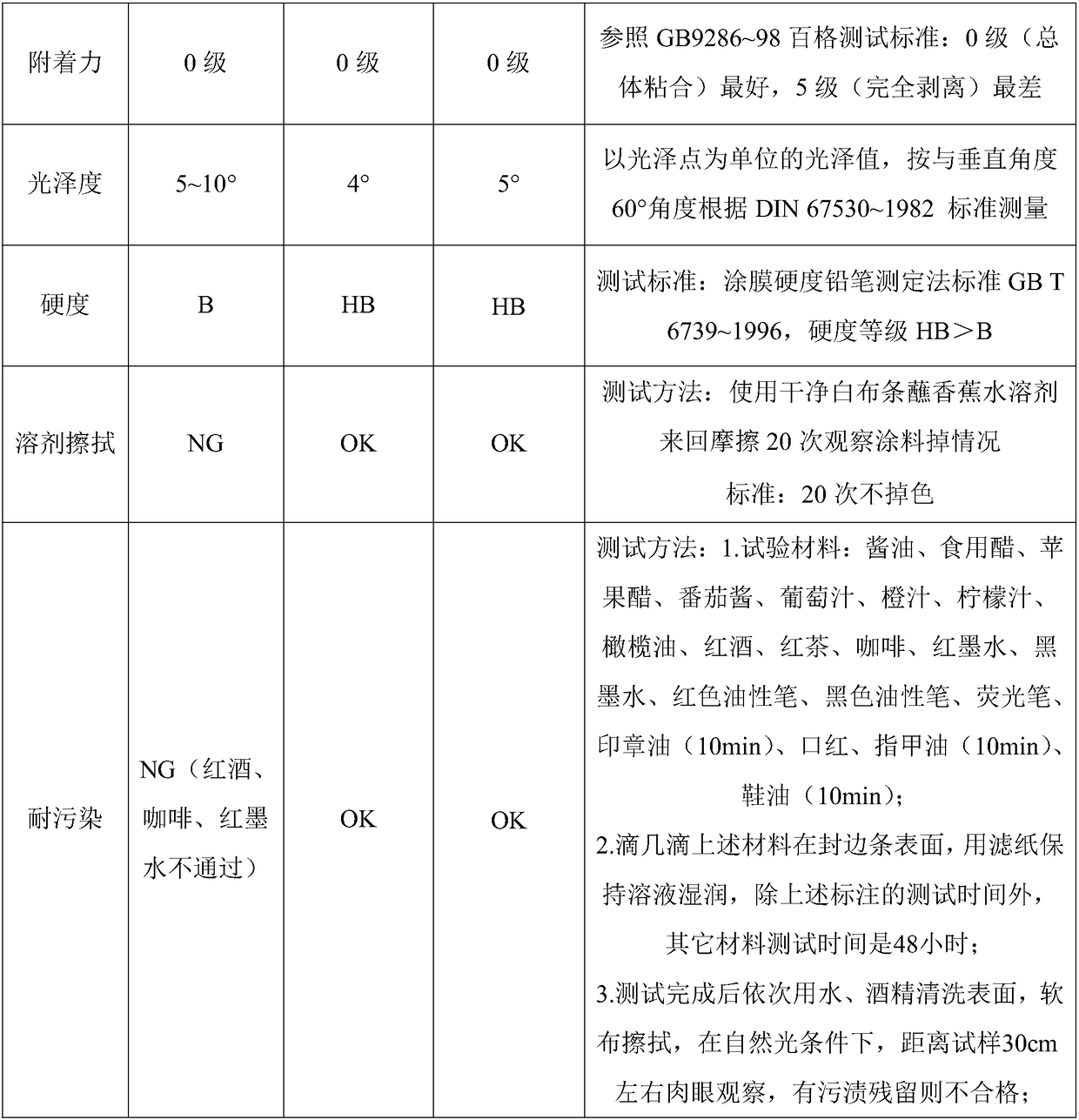

Embodiment 1

[0021] Embodiment 1 of the present invention, the UV varnish extinction modification method comprises the following steps:

[0022] Step 1: Turn on the UV curing equipment N 2 Replace, remove the oxygen in the curing box, so that the oxygen in the curing equipment 2 Concentration≤500PPM;

[0023] Step 2: The PVC substrate is moved at a constant speed of 35m / min driven by the drive wheel of the printing machine, and the high-brightness UV varnish is coated on the surface of the substrate by flexographic printing through a silicone roller, so that the viscosity of the varnish coating is distributed in the 20~25s, the substrate surface temperature is 25℃ during coating;

[0024] Step 3: Use 172nm excimer VUV lamp to radiate and cure the UV varnish for the varnish on the surface of the substrate, and the curing speed is 35m / min;

[0025] Step 4: Use a high-pressure mercury lamp to radiate and cure the UV varnish, the power of the high-pressure mercury lamp is 5KW, and the radia...

Embodiment 2

[0027] Embodiment two of the present invention, the UV varnish extinction modification method comprises the following steps:

[0028] Step 1: Turn on the UV curing equipment N 2 Replace, remove the oxygen in the curing box, so that the oxygen in the curing equipment 2 Concentration≤500PPM;

[0029] Step 2: The ABS substrate is moved at a constant speed of 55m / min driven by the drive wheel of the printing machine, and the ordinary bright UV varnish is coated on the surface of the substrate by flexographic printing through a silicone roller, so that the viscosity of the varnish coating is distributed in the 20~25s, the substrate surface temperature is 25℃ during coating;

[0030] Step 3: Use 172nm excimer VUV lamp to radiate and cure the UV varnish on the surface varnish of the substrate, and the curing speed is 55m / min;

[0031] Step 4: Use a high-pressure mercury lamp to radiate and cure the UV varnish, the power of the high-pressure mercury lamp is 5KW, and the radiation e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com