Long-acting type noctilucent propylene decoration pigment

A propylene, long-lasting technology, applied in the direction of pigment paste, etc., can solve the problems of pigment loss of luster and mechanical properties, luminous effect attenuation, poor storage stability, etc., to achieve stable gloss and mechanical properties, no light attenuation, long-term stability stored effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

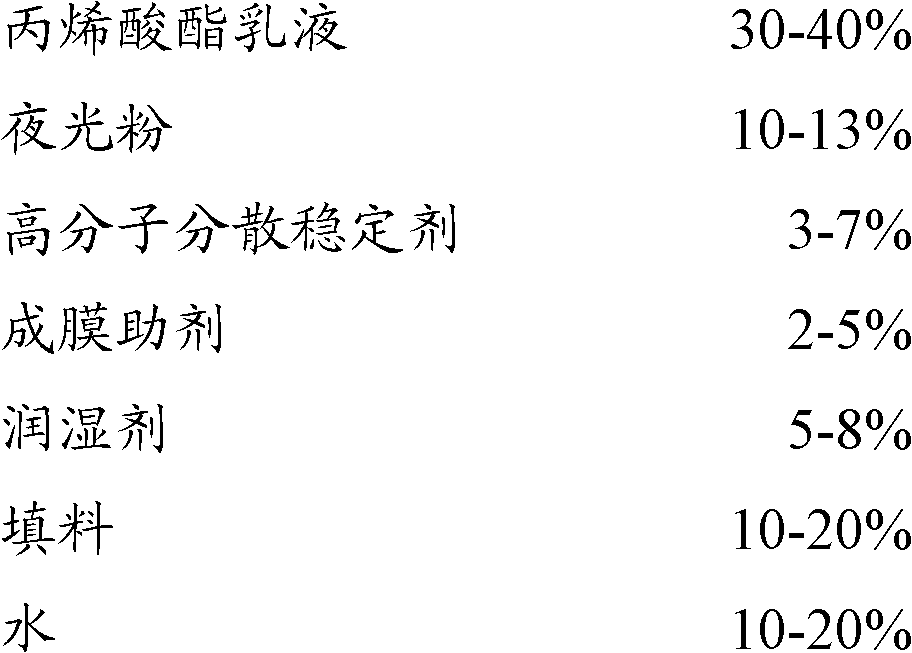

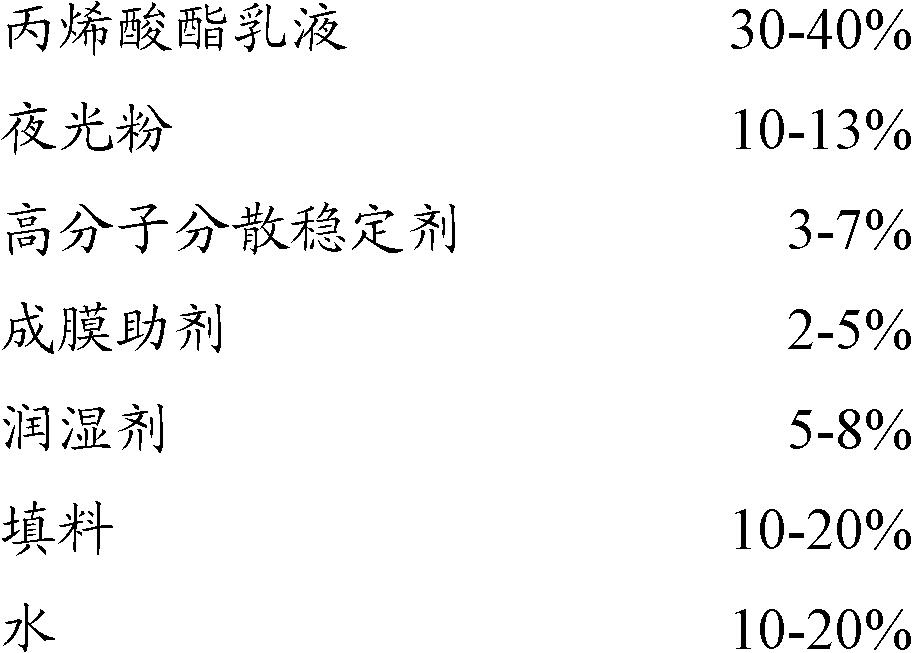

[0020] A long-lasting luminous acrylic decorative pigment, comprising the following components: 30% acrylate emulsion, 12% luminous powder mixed with rare earth dysprosium, europium and aluminum oxide, 7% polyacrylate polymer dispersion stabilizer, lauryl alcohol ester synthetic Membrane aid 5%, non-ionic wetting agent 6%, calcium carbonate filler 20%, deionized water 20%.

[0021] Preparation method: Weigh each component in proportion, add acrylate emulsion, polymer dispersion stabilizer, and wetting agent into the stirring tank and mix evenly, then add luminous powder and mix for 30 minutes while stirring continuously, then add filler and water, The film-forming aid is mixed for 20 minutes to obtain the long-acting luminous acrylic decorative pigment.

Embodiment 2

[0023] A long-lasting luminous acrylic decorative pigment, including the following components: 40% acrylate emulsion, 10% yttrium europium oxide luminous powder, 3% polyacrylate polymer dispersion stabilizer, and 2% lauryl alcohol ester film-forming aid , Non-ionic wetting agent 5%, calcium carbonate filler 15%, heavy calcium filler 5%, deionized water 20%.

[0024] Preparation method: Weigh each component in proportion, add acrylate emulsion, polymer dispersion stabilizer, and wetting agent into the stirring tank and mix evenly, then add luminous powder and mix for 30 minutes while stirring continuously, then add filler and water, The film-forming aid is mixed for 20 minutes to obtain the long-acting luminous acrylic decorative pigment.

Embodiment 3

[0026] A long-lasting luminous acrylic decorative pigment, including the following components: 35% acrylate emulsion, 13% zinc oxide europium luminous powder, 6% polyacrylate polymer dispersion stabilizer, 4% lauryl alcohol ester film-forming aid , Non-ionic wetting agent 7%, heavy calcium filler 15%, deionized water 20%.

[0027] Preparation method: Weigh each component in proportion, add acrylate emulsion, polymer dispersion stabilizer, and wetting agent into the stirring tank and mix evenly, then add luminous powder and mix for 30 minutes while stirring continuously, then add filler and water, The film-forming aid is mixed for 20 minutes to obtain the long-acting luminous acrylic decorative pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com