Safe and environment-friendly semi-matte varnish for automobile interior trim part and preparation method thereof

A technology for automotive interior parts, safety and environmental protection, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of difficult to take into account decorative aesthetics and comfort and durability, and achieve the effects of stable gloss, environmentally friendly preparation process, and improved drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

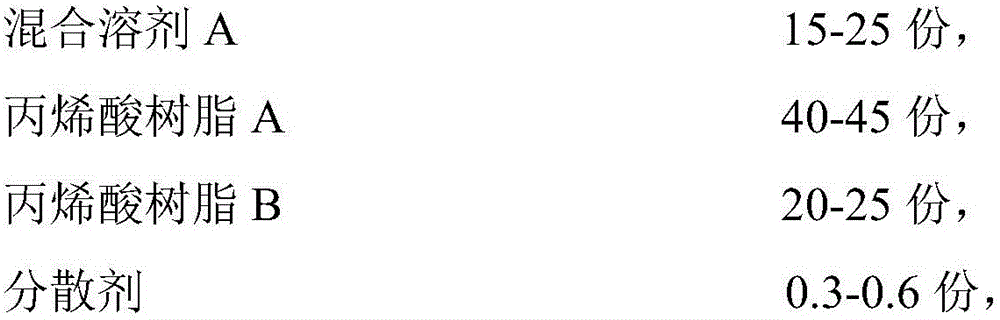

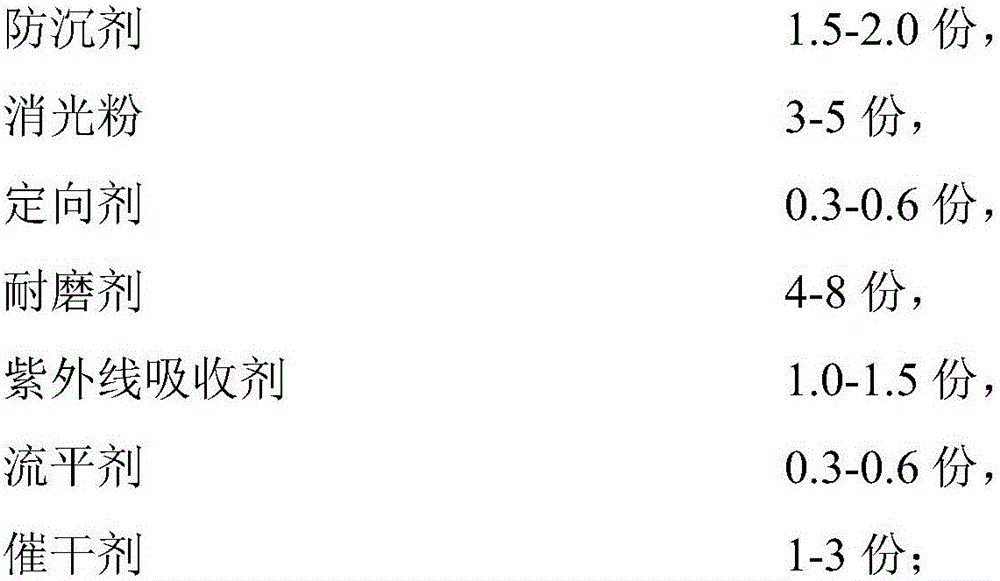

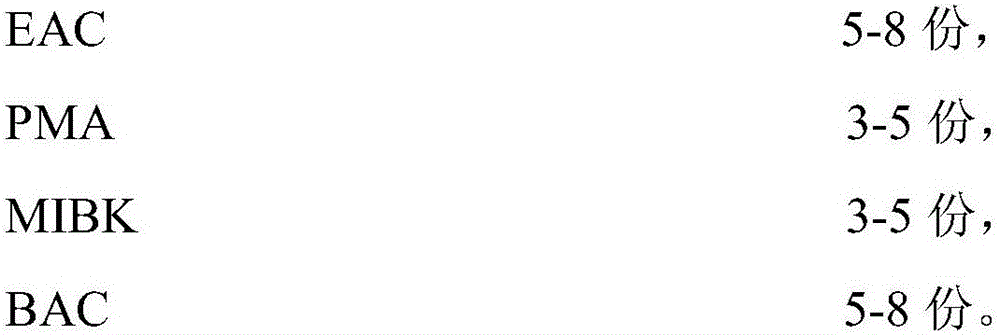

[0036] A preparation method for a safety and environment-friendly semi-matte varnish for automotive interior parts, specifically comprising the following steps:

[0037] (1) Preparation of precursor solution A:

[0038]

[0039]

[0040] Weigh each component according to the above weight parts, first put EAC, PMA, MIBK, BAC, acrylic resin A, acrylic resin B, BYK110 and R972 into the tank, and stir at 400rpm for 6min, then add TS100, Lubrizol 1778 , and stirred at 800-1000rpm for 10min, then ground on a horizontal grinder to make the grinding fineness ≤15μm, then added BYK104S, BASF TINUVIN 292, BYK331, BYK306, and drier and stirred evenly to obtain precursor solution A.

[0041] (2) Preparation of Precursor B:

[0042] Component Parts by weight

[0043] BASF HI90 55

[0044] BAC45

[0045] Weigh each component according to the above parts by weight and add it into the cylinder, stir well and evenly to prepare the precursor solution B.

[0046] Take 250 parts of prec...

Embodiment 2

[0050] A kind of safe environment-friendly semi-matt varnish for automotive interior parts, the varnish comprises the following components and content by weight:

[0051] Precursor solution A 200 parts,

[0052] Precursor solution B 120 parts,

[0053] Wherein, the precursor solution A includes the following components and parts by weight:

[0054]

[0055] Precursor B includes the following components and parts by weight:

[0056] 55 parts of curing agent,

[0057] 45 parts of solvent B.

[0058]Mixed solvent A comprises the following components and parts by weight:

[0059]

[0060]

[0061] In the varnish, acrylic resin A is hydroxyl acrylic resin, acrylic resin B is thermoplastic acrylic resin, dispersant is selected from commercially available EFKA4010, orientation agent is selected from commercially available BYK104S, anti-settling agent is selected from commercially available R972, and leveling agent is selected from commercially available EFKA4010. The ag...

Embodiment 3

[0067] A kind of safe environment-friendly semi-matt varnish for automotive interior parts, the varnish comprises the following components and content by weight:

[0068] Precursor solution A 300 parts,

[0069] Precursor solution B 80 parts,

[0070] Wherein, the precursor solution A includes the following components and parts by weight:

[0071]

[0072] Precursor B includes the following components and parts by weight:

[0073] 45 parts of curing agent,

[0074] 55 parts of solvent B.

[0075] Mixed solvent A comprises the following components and parts by weight:

[0076]

[0077] In this varnish, acrylic resin A is hydroxyl acrylic resin, acrylic resin B is thermoplastic acrylic resin, dispersant is selected from commercially available EFKA5010, orientation agent is selected from commercially available EFKA5065, anti-settling agent is selected from commercially available AS200, leveling The agent is selected from commercially available BYK306, the matting powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com