High-performance corona-resistant powder coating for varnished wire and preparation method and application thereof

A powder coating, enameled wire technology, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor breakdown resistance and corona resistance, and the physical and chemical properties of the coating film cannot solve the corona resistance. Achieve excellent corona damage resistance, improve inter-turn electric field distribution characteristics, and improve thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

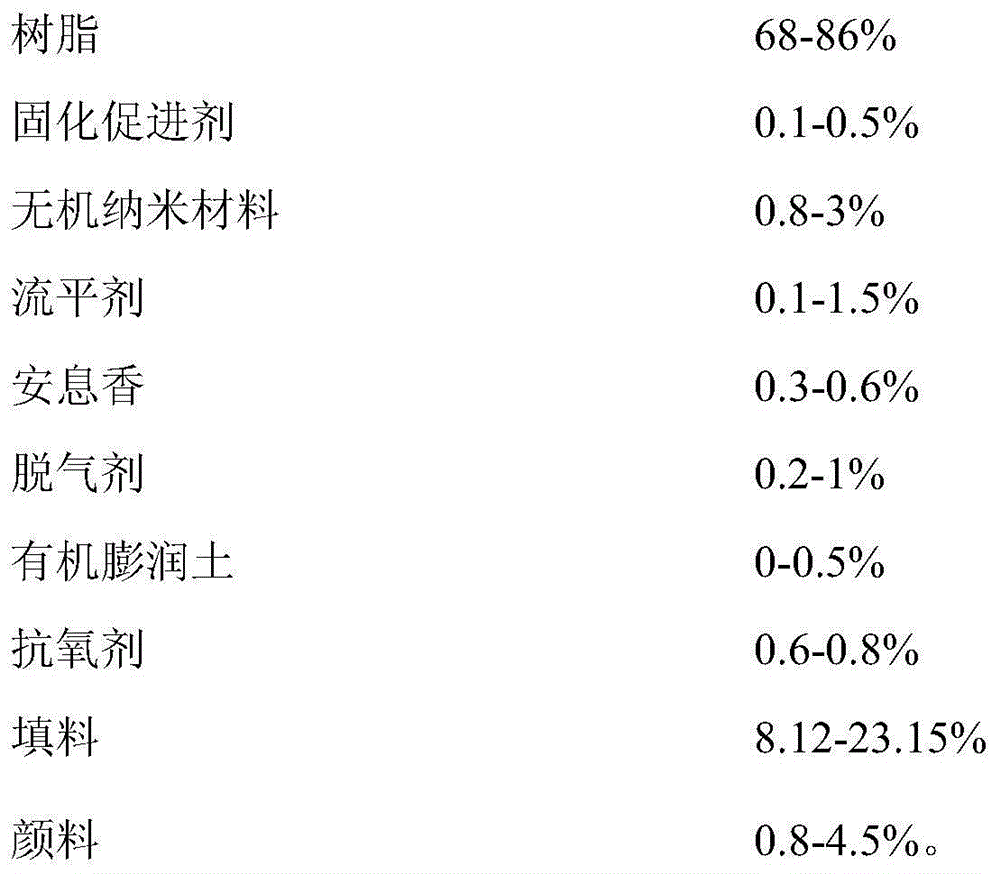

[0030] The high-performance corona-resistant powder coating for enameled wire is made of the following raw materials in weight percentage:

[0031]

[0032] The above raw materials are mixed evenly, melted and extruded by an extruder, tableted, air-cooled, pulverized, sieved, and demagnetized to obtain a high-performance corona-resistant powder coating for enameled wires.

[0033] The high-performance corona-resistant powder coating for enameled wire prepared in this example is sprayed on the surface of the workpiece with an electrostatic spray gun, the voltage is controlled at 82kV, and the air pressure is controlled at 0.20MPa, and then it is heated and cured in an electric blast drying oven at a curing temperature of 200 ℃, curing time is 8min.

[0034] The performance test results of the obtained coating film after curing are shown in Table 1.

[0035] Table 1 Performance Test Results of Example 1

[0036]

[0037]

Embodiment 2

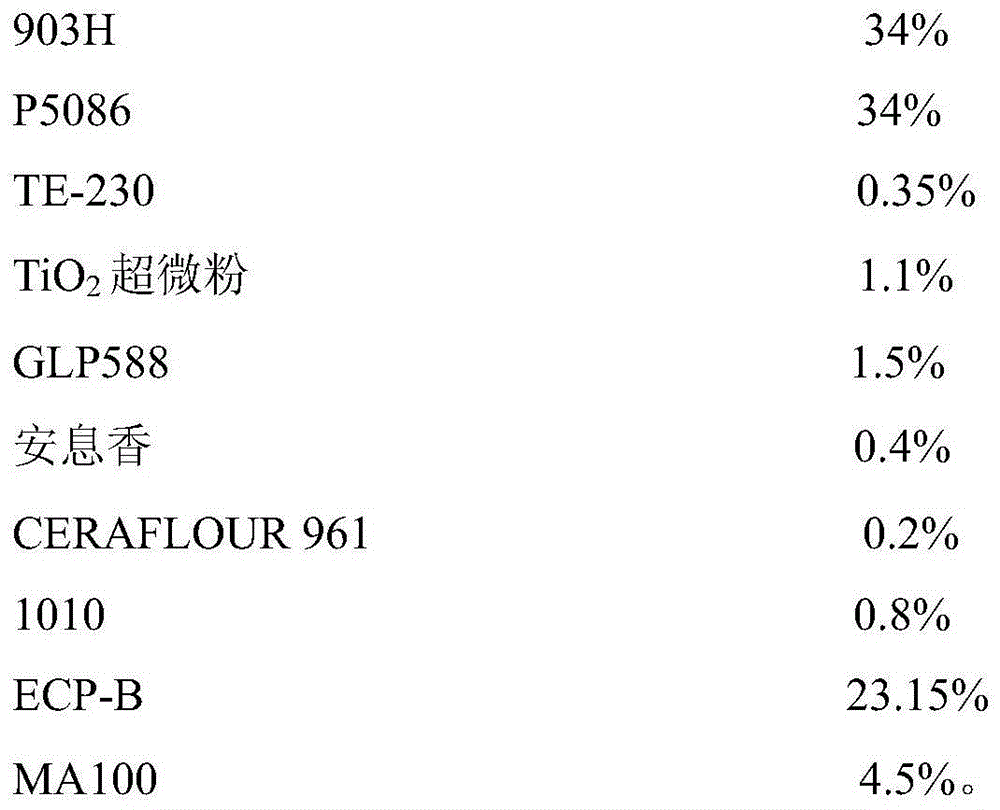

[0039] The high-performance corona-resistant powder coating for enameled wire is made of the following raw materials in weight percentage:

[0040]

[0041] The above raw materials are mixed evenly, melted and extruded by an extruder, tableted, air-cooled, pulverized, sieved, and demagnetized to obtain a high-performance corona-resistant powder coating for enameled wires.

[0042] The high-performance corona-resistant powder coating for enameled wire prepared in this example is sprayed on the surface of the workpiece with an electrostatic spray gun, the voltage is controlled at 88kV, and the air pressure is controlled at 0.23MPa, and then it is heated and cured in an electric blast drying oven at a curing temperature of 190 ℃, curing time is 10min.

[0043] The performance test results of the obtained coating film after curing are shown in Table 2.

[0044]Table 2 Example 2 Performance Test Results

[0045]

[0046]

Embodiment 3

[0048] The high-performance corona-resistant powder coating for enameled wire is made of the following raw materials in weight percentage:

[0049]

[0050] The above raw materials are mixed evenly, melted and extruded by an extruder, tableted, air-cooled, pulverized, sieved, and demagnetized to obtain a high-performance corona-resistant powder coating for enameled wires.

[0051] The high-performance corona-resistant powder coating for enameled wire prepared in this example is sprayed on the surface of the workpiece with an electrostatic spray gun, the voltage is controlled at 86kV, the air pressure is controlled at 0.21MPa, and then it is heated and cured in an electric blast drying oven at a curing temperature of 180 ℃, curing time is 12min.

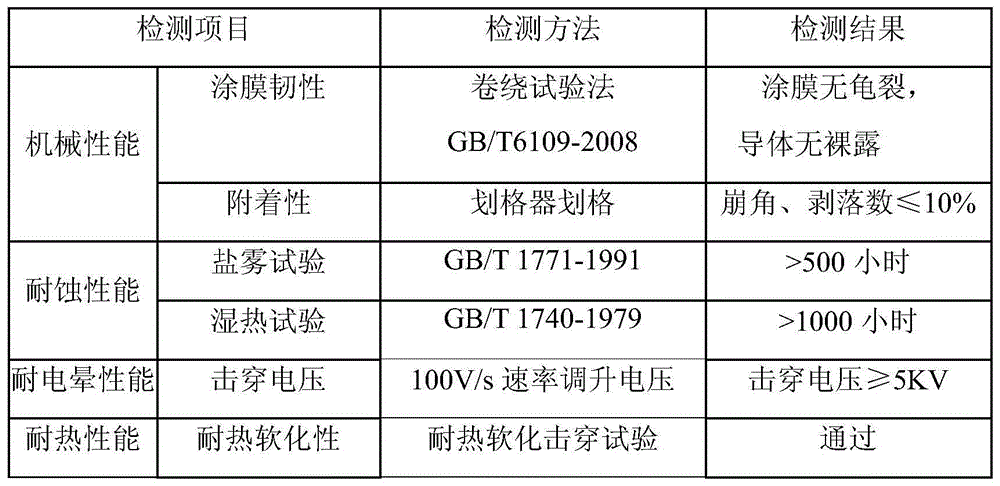

[0052] The performance test results of the obtained coating film after curing are shown in Table 3.

[0053] Table 3 Example 3 coating film performance testing results

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com