60/40 low-gloss polyester resin for powdery coating, and three-kettle combined preparation method thereof

A polyester resin, powder coating technology, applied in powder coatings, polyurea/polyurethane coatings, polyester coatings, etc., can solve problems such as large differences in gloss, limited application, and poor batch stability of powder coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

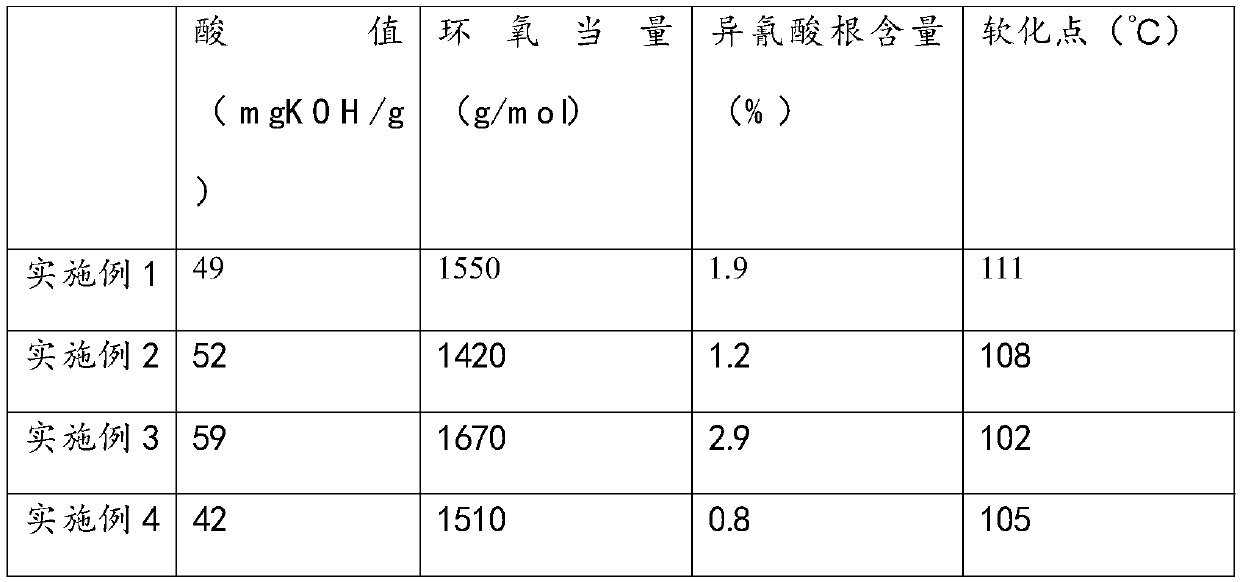

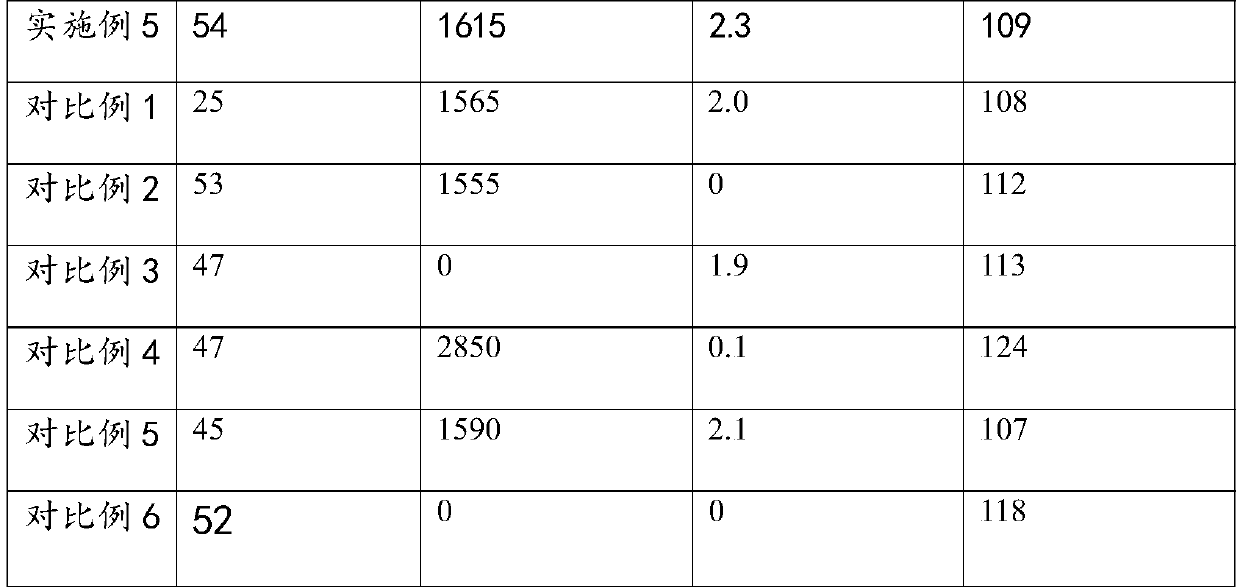

Examples

Embodiment 1

[0042] The preparation method of the polyester resin that is used for 60 / 40 low light type powder coating, comprises the following steps:

[0043] (1) 3,7-dimethyl-1,7-octanediol, 3-nitrophthalic anhydride, 2,2'-bipyridine-4,4'-dicarboxylic acid ethyl ester and catalyst A Add it into the reaction kettle A, and conduct the esterification reaction at 200°C for 11 hours, stop the reaction when the acid value drops to about 45KOH / g, and obtain the first esterification material;

[0044] (2) Add trimesic acid to the first esterification material, gradually heat up to 240°C at a rate of 5°C / h under nitrogen protection, start the vacuum system, keep the vacuum at about 65mmHg, and keep the temperature for 3h. Stop the reaction when the acid value drops below 120mgKOH / g, cool down to 135°C and keep it warm for later use to obtain polyester material A;

[0045] (3) Add terephthalic acid, diethylene glycol, 1,4-bis(hydroxymethyl)cyclohexane and catalyst B into reaction kettle B, and ca...

Embodiment 6

[0068] After the polyester resin of the present invention is applied to the coating, whether the coating performance can reach the desired expected effect, the inventor has done the following experiments:

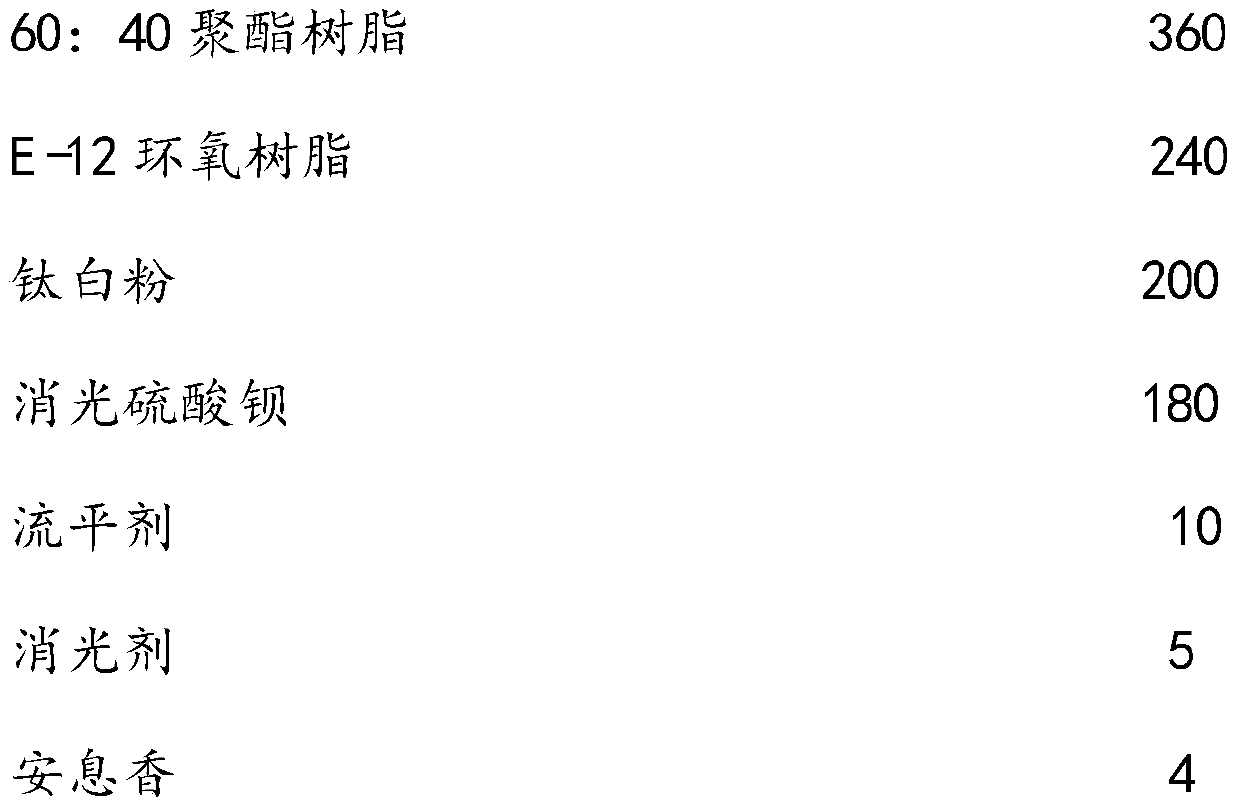

[0069] Using the existing 60 / 40 matting powder coating formula, the formula is usually as follows in parts by weight:

[0070]

[0071] The matting agent code-named M-30 was purchased from Anhui Jingcheng New Material Co., Ltd.;

[0072] Paint coating preparation: According to the formula of low-gloss powder paint, mix the materials, extrude, tablet, and crush with a twin-screw extruder, and then crush the flakes and sieve (160 mesh) to make a powder paint. The powder coating is sprayed on the surface-treated tinplate substrate with an electrostatic spray gun, and cured at 180°C / 15min to obtain the coating.

[0073] The determination of acid value is based on GB / T 12008.5-1989 "Determination of Acid Value in Polyether Polyols";

[0074] The test method of epoxy equival...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com