Cast AlSi7Mg alloy and modification and refinement method thereof

A treatment method and a modificator technology, which are applied in the field of casting AlSi7Mg and its modification and refinement treatment, can solve the problems of poor elongation, batch scrapping of castings, and low casting strength, so as to ensure physical and mechanical properties, improve product stability, Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

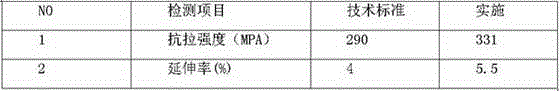

Examples

Embodiment 1

[0037] Step 1: Weigh 600 kilograms of AlSi7Mg aluminum ingots and melt them into molten aluminum in a melting furnace with a set temperature of 760°C;

[0038] Step 2: transfer the obtained molten aluminum to the holding furnace at 750-760°C, set the temperature of the holding furnace at 720°C, and cool down the molten aluminum in the holding furnace;

[0039] Step 3: Measure the temperature of the molten aluminum in the holding furnace. When the temperature of the molten aluminum is 720°C, add 1.0 kg of modifier AlSr10 master alloy and 0.18 kg of refiner AlTi5B master alloy and stir for 1 minute;

[0040] Step 4: GBF nitrogen degassing for 8 minutes;

[0041] Step 5: Manually remove oxides and slag on the surface of molten aluminum;

[0042] Step 6: AlSi7Mg aluminum liquid pouring

[0043] 1. After preheating the mold to 180~250℃, spray a layer of coating agent;

[0044] 2. The mold is preheated to 200~300°C to close the mold and pour aluminum liquid;

[0045] 3. Timing s...

Embodiment 2

[0051] Step 1: Weigh 600 kilograms of AlSi7Mg aluminum ingots and melt them into molten aluminum in a melting furnace with a set temperature of 760°C;

[0052] Step 2: transfer the obtained molten aluminum to the holding furnace at 750-760°C, set the temperature of the holding furnace at 720°C, and cool down the molten aluminum in the holding furnace;

[0053] Step 3: Measure the temperature of the molten aluminum in the holding furnace. When the temperature of the molten aluminum is 720°C, add 0.48 kg of modifier AlSr10 master alloy and 0.09 kg of refiner AlTi5B master alloy and stir for 1 minute;

[0054] Step 4: GBF nitrogen degassing for 8 minutes;

[0055] Step 5: Manually remove oxides and slag on the surface of molten aluminum;

[0056] Step 6: AlSi7Mg aluminum liquid pouring

[0057] 1. After preheating the mold to 180~250℃, spray a layer of coating agent;

[0058] 2. The mold is preheated to 200~300°C to close the mold and pour aluminum liquid;

[0059] 3. Timing ...

Embodiment 3

[0062] Step 1: Weigh 600 kilograms of AlSi7Mg aluminum ingots and melt them into molten aluminum in a melting furnace with a set temperature of 760°C;

[0063] Step 2: transfer the obtained molten aluminum to the holding furnace at 750-760°C, set the temperature of the holding furnace at 720°C, and cool down the molten aluminum in the holding furnace;

[0064] Step 3: Measure the temperature of the molten aluminum in the holding furnace. When the temperature range of the molten aluminum is between 720°C, add 1.2 kg of the modifier AlSr10 master alloy and 0.27 kg of the refiner AlTi5B master alloy and stir for 1 minute;

[0065] Step 4: GBF nitrogen degassing for 8 minutes;

[0066] Step 5: Manually remove oxides and slag on the surface of molten aluminum;

[0067] Step 6: AlSi7Mg aluminum liquid pouring

[0068] 1. After preheating the mold to 180~250℃, spray a layer of coating agent;

[0069] 2. The mold is preheated to 200~300°C to close the mold and pour aluminum liquid;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com