Modified PP foaming enhanced material and preparation method thereof

A reinforcing material and modification technology, applied in the field of polymer material modification, can solve the problems of no physical and mechanical properties, low density, etc., and achieve the effects of easy control of process conditions, high production efficiency, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

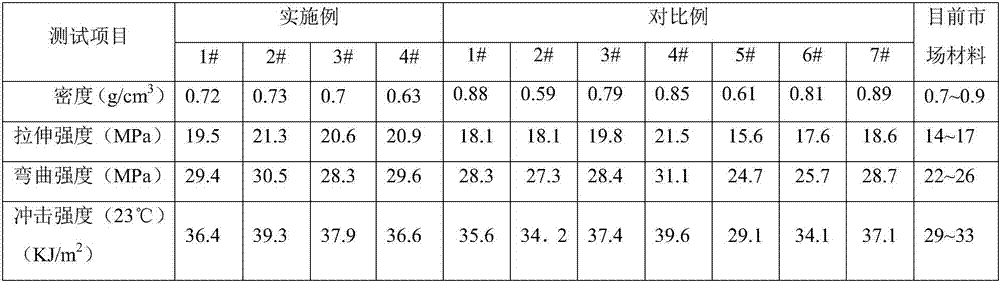

Examples

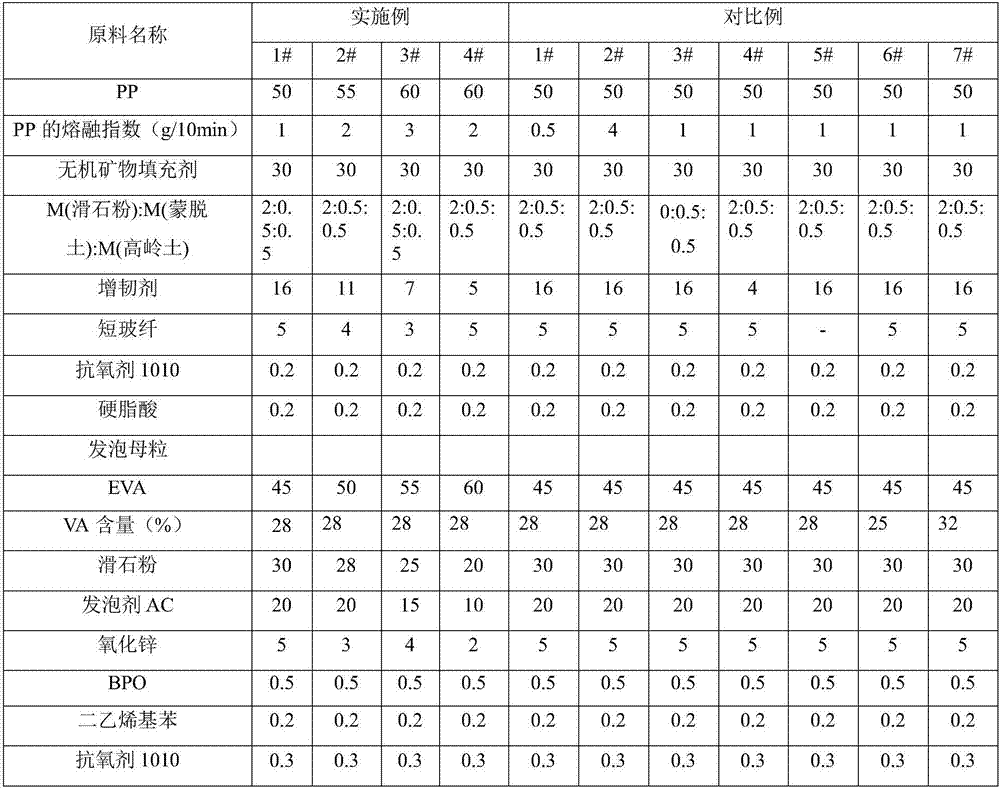

Embodiment 1

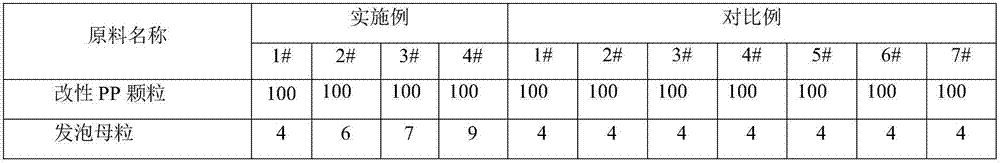

[0039] A modified PP foam reinforcement material is composed of modified PP particles and foam masterbatch, and the mass ratio of the two is 100:4.

[0040] Wherein, each component of the modified PP particles is calculated in parts by mass as follows:

[0041] PP: 50 parts

[0042] Inorganic mineral filler: 30 parts

[0043] Toughener: 16 parts

[0044] Short fiberglass: 5 parts

[0045] Antioxidant 1010: 0.2 parts

[0046] Stearic acid: 0.2 parts.

[0047] Wherein, each component of described foam masterbatch is counted as in parts by mass:

[0048] EVA: 45 parts

[0050] Azodicarbonamide (AC): 20 parts

[0052] Benzoyl peroxide (BPO): 0.5 parts

[0053] Divinylbenzene: 0.2 parts

[0054] Antioxidant 1010; 0.3 parts.

[0055] The melt index of the PP is 1g / 10min.

[0056] The inorganic mineral filler is composed of talcum powder, montmorillonite and kaolin in a mass ratio of 2:0.5:0.5.

[0057] The tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com