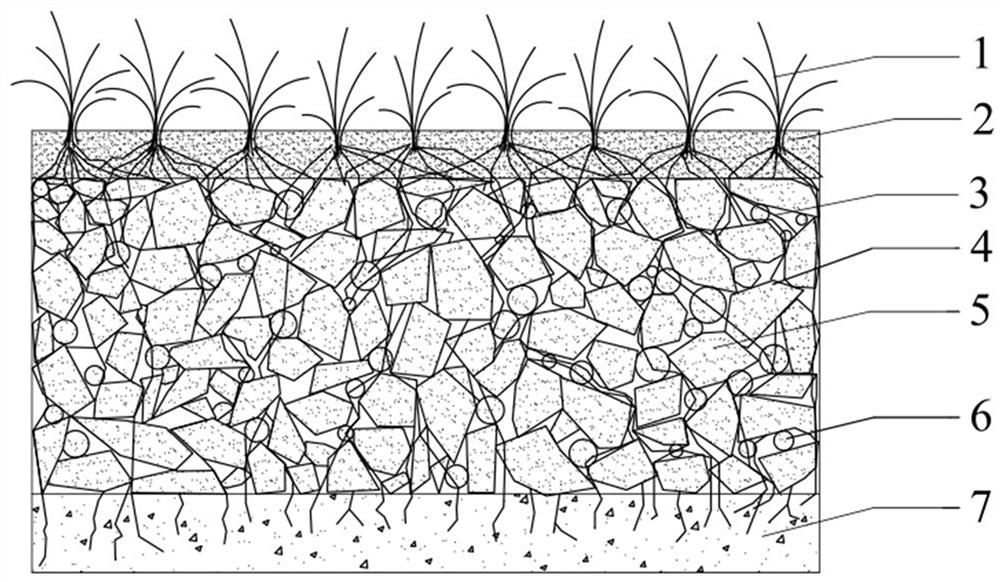

Ecological concrete containing nutritional base material particles and preparation method thereof

An ecological concrete and nutrient-based technology, applied in ceramic products, fertilizer mixtures, other household appliances, etc., can solve the problems of inconspicuous ecological performance of ecological concrete, loss of soil and nutrients, plant re-germination and growth difficulties, etc. The effect of long-term dependent growth improvement, good fertilizer effect slow release performance, good water retention and moisture retention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041]In addition, the present invention also discloses the preparation method of the above-mentioned ecological concrete containing nutrient substrate particles, which comprises the following steps:

[0042] S1. Take various raw materials for preparing nutrient substrate particles, and mix them thoroughly to obtain a mixture;

[0043] S2, adding the mixture in step S1 into water and stirring evenly and then performing a granulation process to form nutrient substrate particles;

[0044] S3, curing the prepared nutrient substrate particles; in this embodiment, the nutrient substrate particles after granulation and curing should have high strength, and the breakage rate during the mixing process of ecological concrete raw materials is not higher than 5 %, it is not easy to disintegrate under the action of water immersion and scouring, and the internal nutrients are not easy to lose. The granulated nutrient substrate granules should be cured for 3 to 28 days, and the curing humi...

Embodiment 1

[0055] The preparation process and method of the nutrient substrate particles are as follows:

[0056] (1) Select the weathered laterite, dry it in the sun and pulverize it, and sieve it through a fine sieve to obtain slightly acidic soil matrix powder.

[0057] (2) after the sawdust and coconut shell crushed powder are mixed according to 1:1, they are mixed with the humus nutrient soil obtained by fermentation, and the mixing ratio is the organic matter powder: the nutrient soil is 1:3 to obtain the plant organic matter powder rich in organic matter.

[0058] (3) Take 60 parts of the screened soil matrix, 20 parts of plant organic matter powder, 6 parts of slow-release organic fertilizer, acid-base regulator (2 parts of superphosphate fertilizer, 2 parts of ferrous sulfate), water retention agent (polymer water absorption Resin (SPA)) 0.1 part, mix the materials evenly to obtain the mixture containing the nutrient base material for use;

[0059] (4) mixing the mixture prepar...

Embodiment 2

[0080] (1) Adjusting the ratio of sawdust and coconut shell components in Example 1, adding 0.5 part of solid sodium silicate, or adding 10 parts of polyvinyl acetate emulsion as a gelling material, can prepare a suitable nutritional substrate bone It shows that the organic matter and binder in the nutrient substrate particles have relatively wide sources, flexible ingredients and good adaptability. The actual measurement shows that after adjusting the mass ratio of sawdust and coconut shell components to be 2:1, the bulk density of the nutrient base aggregate particles in this example is reduced to 650kg / m 3 . The pH value of the nutrient-based aggregate particles is 8.56, the average 28d splitting compressive strength is 0.44MPa, the impact crushing rate is less than 3%, the water absorption rate is 42.0%, the water stability is still good, and the particle strength and hardness are high, which meets the ecological requirements. Concrete preparation requirements.

[0081] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com