Pressure grouting experiment device

An experimental device and pressure grouting technology, applied in the field of experimental devices, can solve problems such as the difficulty of researching grouting diffusion radius, and achieve the effect of being small, convenient and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

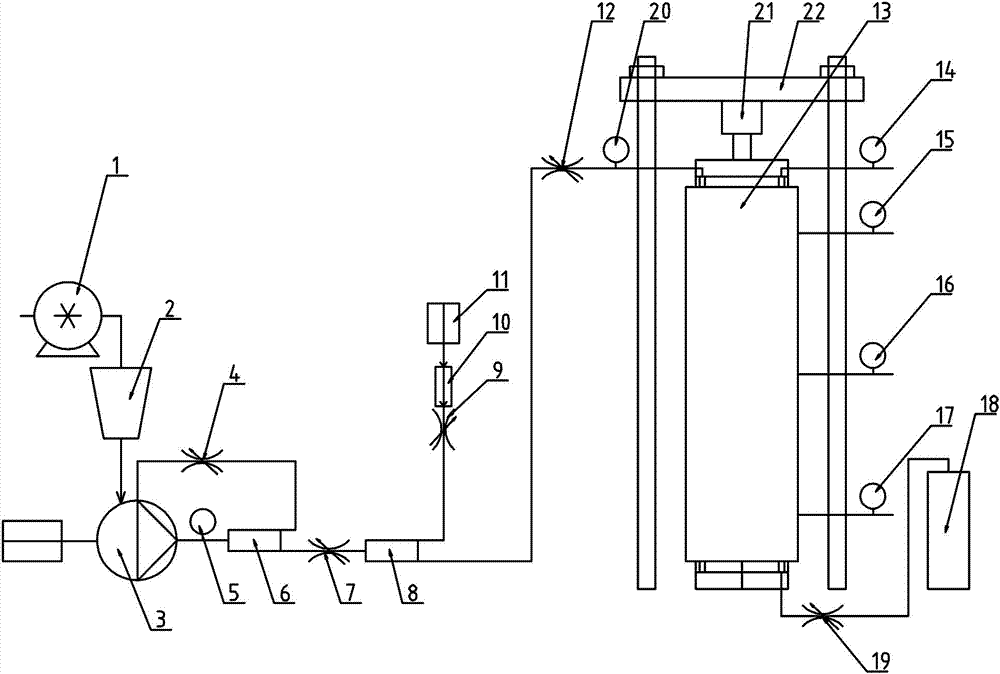

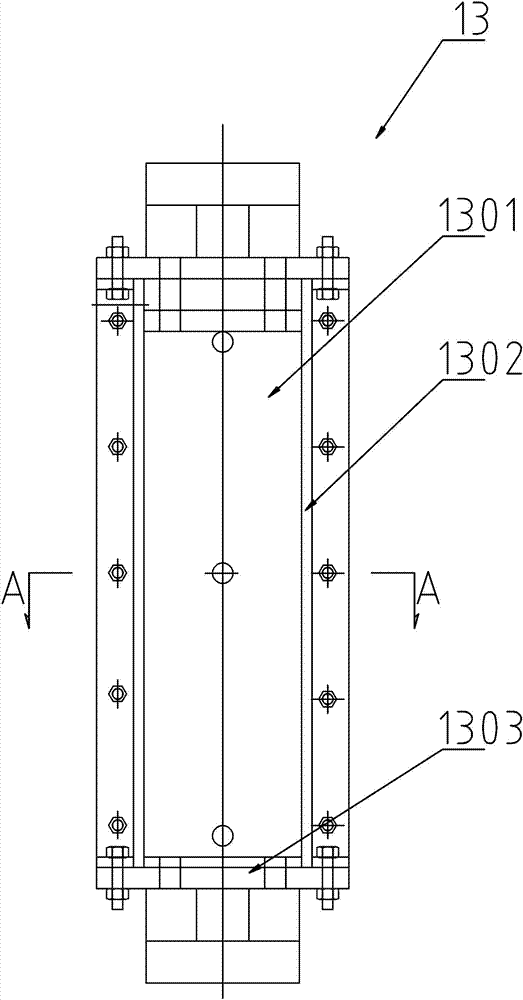

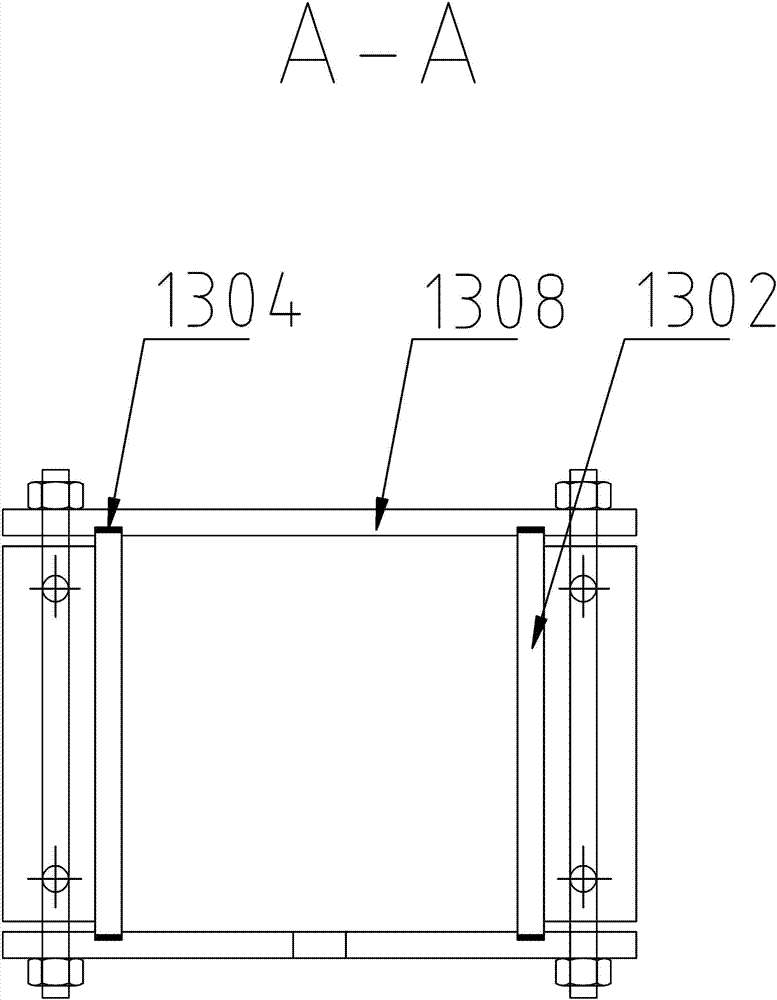

[0033] Such as figure 1 Among them, a pressure grouting experimental device, including a slurry supply device, the slurry supply device is communicated with the slurry hole 1305 of the experimental mold 13, and the lower slurry hole of the experimental mold 13 is communicated with the slurry recovery bucket 18;

[0034] A plurality of pipelines are arranged on the outer wall of the experimental mold 13 from top to bottom, and pressure gauges are arranged on the pipelines;

[0035] Throttle valves are provided between the slurry supply device and the experimental mold 13 and between the experimental mold 13 and the slurry recovery bucket 18 .

[0036] Such as figure 1 Among them, the grout supply device includes a grout pump 3, and the grout outlet of the grout pump 3 communicates with the first diverter 6, and one diverter end of the first diverter 6 communicates with the grout hole of the experimental mold 13, and the other diverter The end communicates with the grouting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com