Steaming-free production technology for PHC pipe pile and application of steaming-free production technology

A technology of PHC pipe piles and production technology, which is applied in the field of construction and can solve the problems of concrete early strength decline, adverse effects of pipe pile performance, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

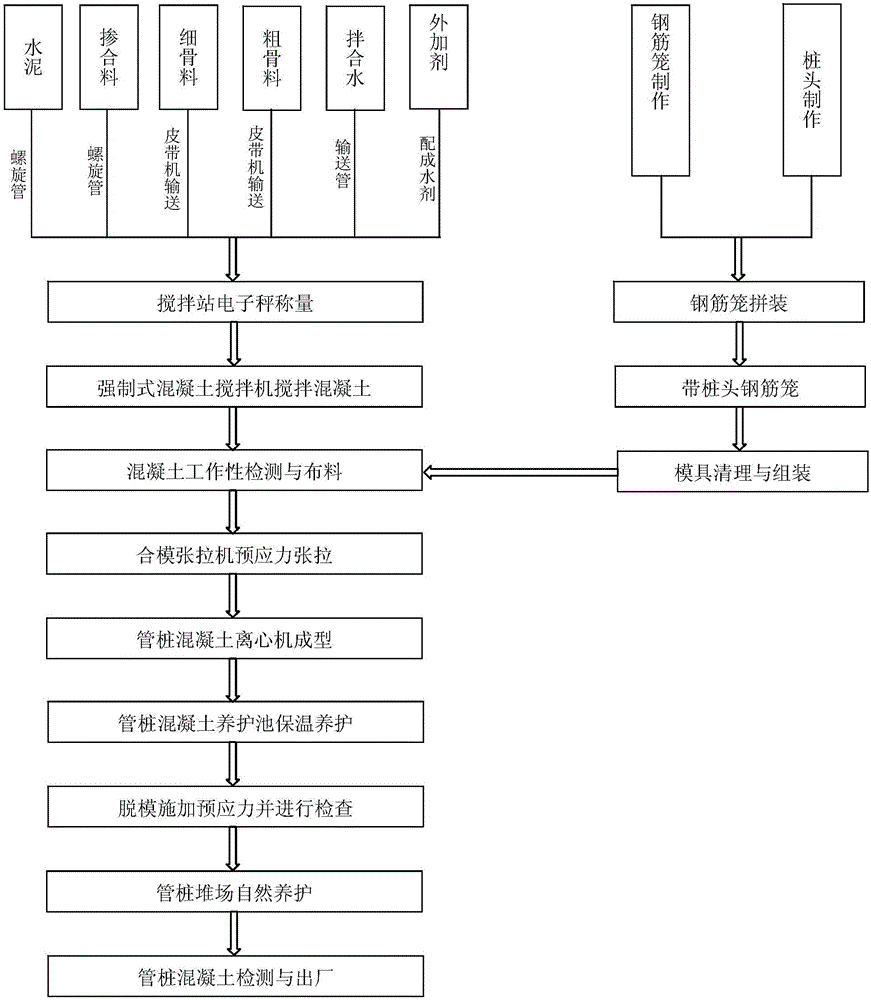

Method used

Image

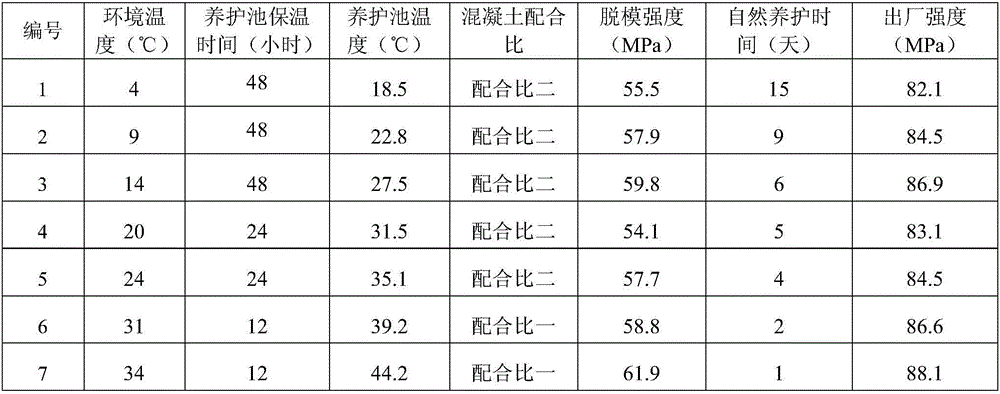

Examples

Embodiment 1

[0126] 1. Raw materials

[0127] Cement: The strength grade is 52.5 type II portland cement.

[0128]Slag powder: granulated blast furnace slag powder with a strength grade of S115.

[0129] Fly ash microbeads: the water demand ratio is 80wt%, and the 7-day activity index is 85%.

[0130] Sand: medium sand with a fineness modulus of 2.7, a mud content of 0.5 wt%, and a mud content of 0.2 wt%.

[0131] Crushed stone: 5-25mm continuous graded crushed stone (made from 5-10mm and 16-25 grades, the mass ratio of 5-10mm to 16-25mm is 3:7), with a mud content of 0.5wt %, the mud content is 0.1wt%.

[0132] Water reducer: Shanghai Huadeng HP400 early-strength polycarboxylate high-efficiency water reducer.

[0133] Mixing water: use city tap water.

[0134] Early strength agent one: lithium sulfate.

[0135] Early strength agent two: triethanolamine.

[0136] 2. Concrete mix ratio (see Table 3)

[0137] Table 3 Mixing ratio of steam-free concrete (kg / m 3 )

[0138] N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com