Atmospheric cationic dye dyeable copolyester polymer, manufacturing method thereof, and atmospheric cationic dye dyeable copolyester fiber using the same

A cationic dye and atmospheric pressure technology, applied in the field of copolyester fiber, can solve the problems of industrial production and expensive catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

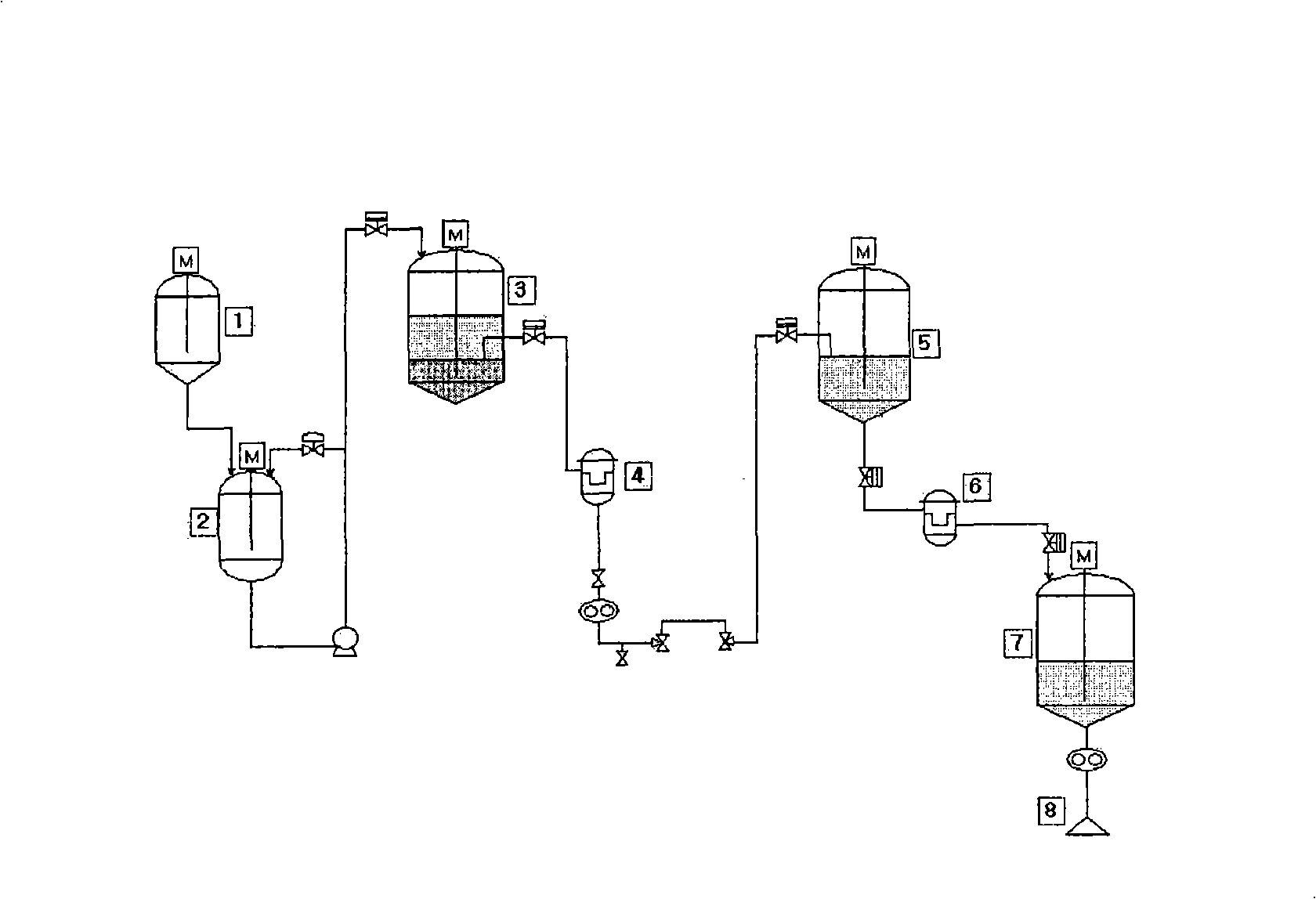

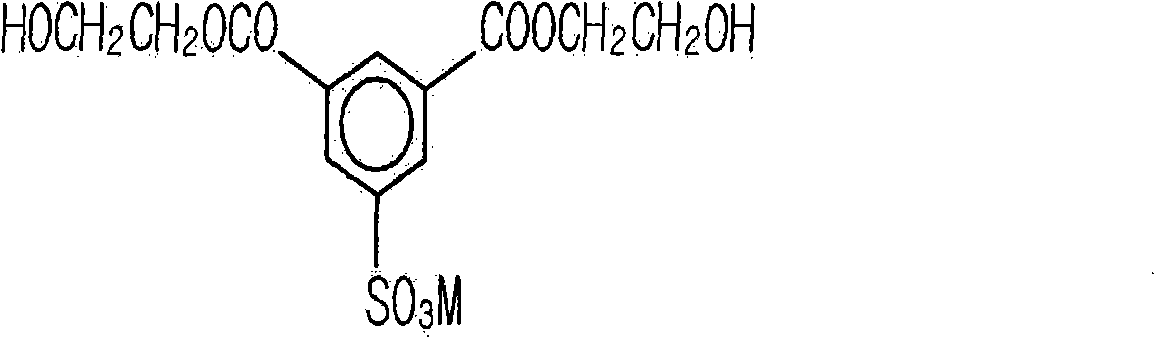

[0052] Adipic acid (AA) was used as dibasic fatty acid. TPA, AA, and EG were mixed (TPA:AA:EG=600:315:50 by volume ratio) to prepare a slurry. The resulting slurry was continuously fed into a DE-1 reaction tank (see figure 1 ), wherein the DE-1 reaction tank contained 1.3 tons of molten base oligomer (which contained 8.7 mol% adipic acid based on the total dibasic acid), and the reaction tank was maintained at 255°C. The slurry was fed until the amount of polymer reached 1.5 tons and the esterification reaction was carried out for 30 minutes, and then 1.5 tons of oligomers were transferred to the DE-2 reaction tank using a metering pump. To this oligomer, add DES (its molecular weight is 356, dissolved in EG at a concentration of 35% by weight) represented by 1.3 mol% of the total dibasic acids (TPA, AA and DES) shown in Chemical Formula 1, wherein the chemical formula M in 1 is Na. Stir well and transfer the mixture to the polycondensation tank (see figure 1 ), and then a...

Embodiment 2

[0054] A polymer was prepared in the same manner as in Example 1, except that AA was replaced with azelaic acid (AZA) at 8.5 mol% of the total dibasic acids. The physical properties of the obtained polymers are listed in Table 1.

Embodiment 3

[0056] A polymer was prepared in the same manner as in Example 1, except that DES in which M was Li was added. The physical properties of the obtained polymers are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com