Stained paper for surface decoration of glass partition, glass and mirror face and manufacture process thereof

A surface decoration and glass technology, applied in the field of transparent plastic decals and its manufacturing, can solve the problems of light transmission and opacity, high decorative requirements, blocking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

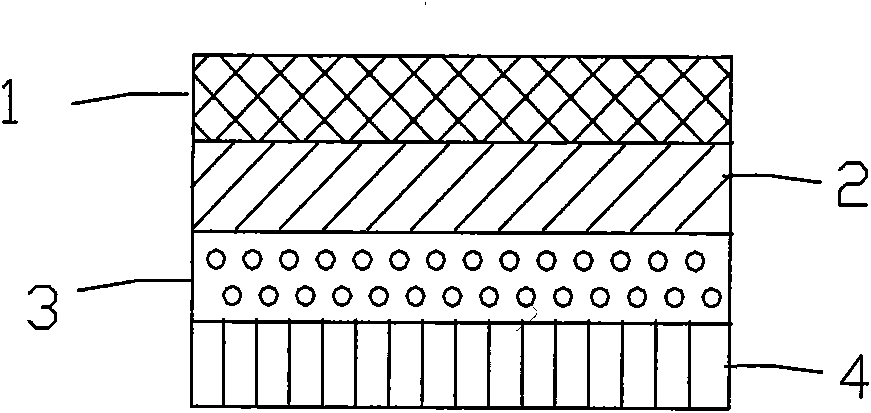

[0085] refer to figure 1 , a glass wallpaper, the main body is composed of a protective film layer 4, an adhesive layer 3, a substrate layer 2 and a process layer 1, wherein the substrate layer 2 is made of a transparent plastic film material, generally a transparent medium-temperature to high-temperature PET film, According to actual needs such as fire protection, it can be replaced with but not limited to transparent reinforced PVC (polyvinyl chloride) film or PC (polycarbonate), composite plastic film and other transparent plastic films, and explosion-proof film, heat insulation film, etc. can also be directly used Material. If PVC film is used, its process is preferably film made by casting method. The film is relatively thin and the water ripples are not obvious. Add stabilizers and other additives to increase its processing temperature. The material thickness of the substrate layer is between 4cm-35cmm, preferably 5-15cmm. The heat-resistant temperature of the material ...

Embodiment 2

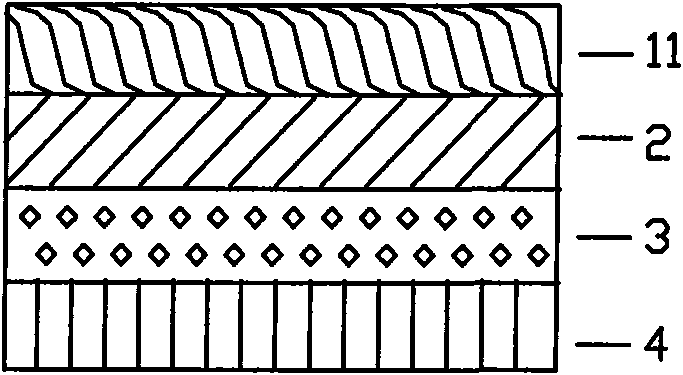

[0098] The process layer adopts the flocking process, and the 14 steps of forming the flocking process layer are:

[0099] The material generally uses transparent plastic films such as medium-to-high temperature PET or PVC as the substrate, and the glue uses transparent flocking pulp, EVA glue and other water-based glue, or oily glue, or matte film UV ink, crystal UV ink, UV ink, etc. glue. The sheet packaging also adopts the screen printing method. After printing the screen and printing the glue layer on the transparent plastic film, it is sent to the flocking room, and the fluff layer is planted under the action of static electricity, and then it is dried or UV cured, and the brush is cleaned. Finish. The package also adopts gravure printing or rotary screen method. The principle of gravure printing is the same as that described above, and the glue layer is made; the rotary screen is designed with a pattern, and the rotary screen is printed to make a net, and the glue is pu...

Embodiment 3

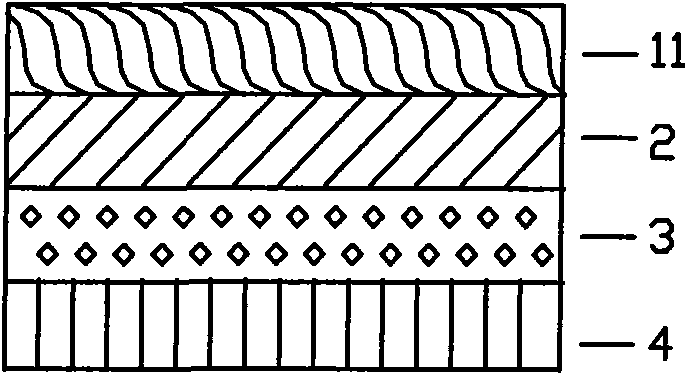

[0102] Make the crystal craft layer 15 with the crystal dripping process, and the steps are:

[0103] This method is generally made by combining UV ink technology. First use UV ink to make transparent UV ink layer or color ink layer and other effects, and then use soft epoxy resin to fully mix AB components according to the metering coefficient ratio for 3-20 minutes. , and then use a needle tube and other tools to drop on the specified pattern UV ink surface. This process is generally only suitable for a small amount of embellished sheet production, not suitable for roll production. The table must be very flat during production, and can be adjusted with tools such as a level desktop. Since the epoxy resin is liquid and has strong fluidity after preparation, the finished shape is easy to lose shape, so the prepared epoxy resin can be left for 0.2-3 hours during the production, and the viscosity of the resin increases before dripping , Thick glue has poor fluidity, so you can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com