Trunnion-free grip-holder used for forge

A technology for forging and hinge shafts, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. It can solve problems such as chucks protruding into the furnace, short moment of arm, and shell tearing. , to achieve the effects of low manufacturing cost, accurate position of picking and placing blanks, and large clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

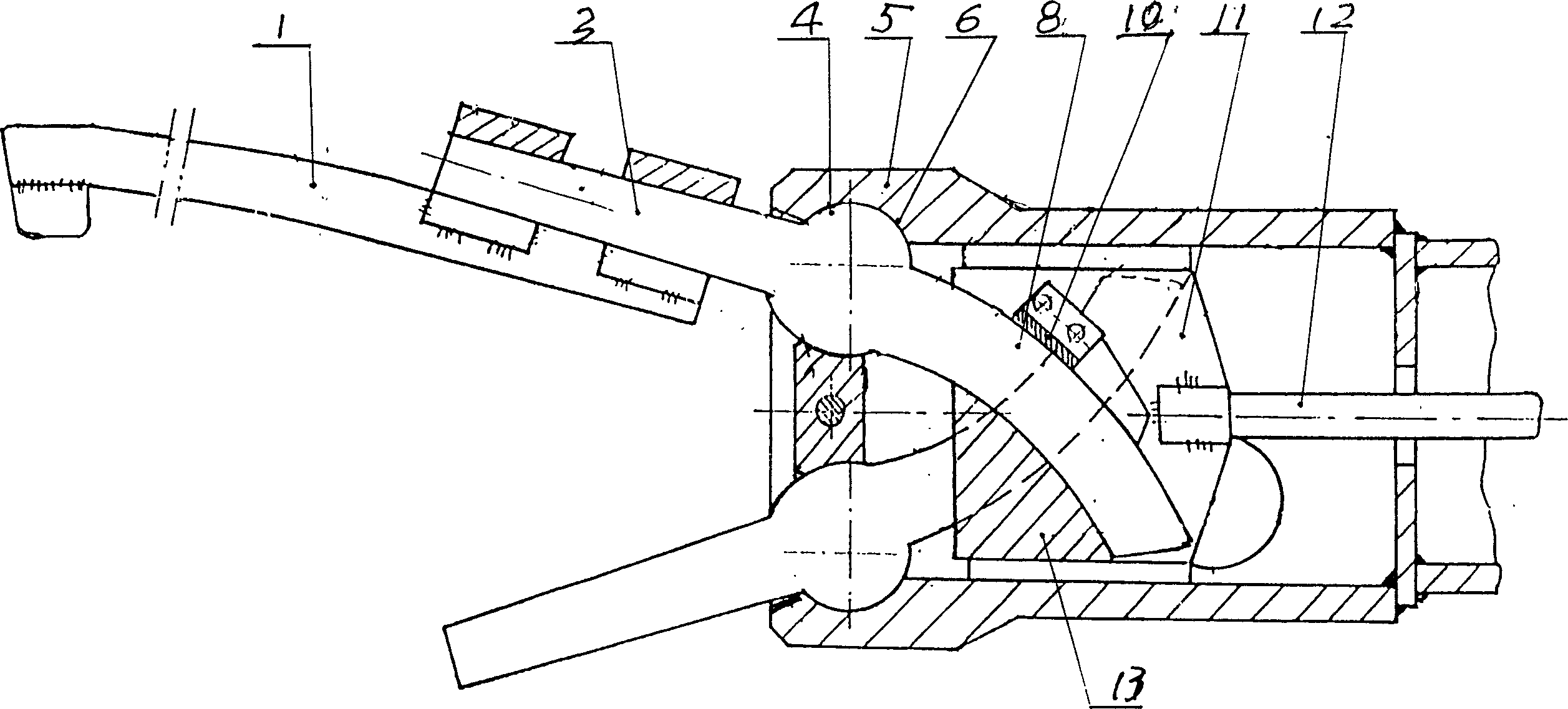

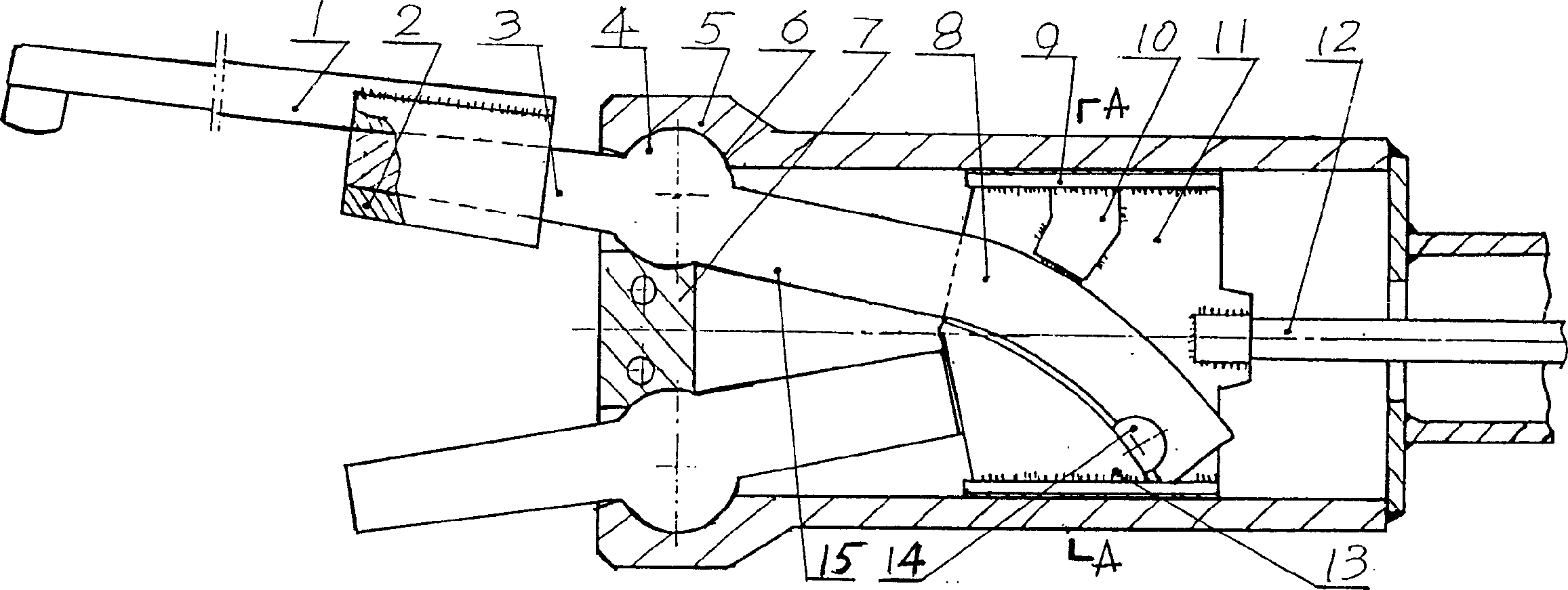

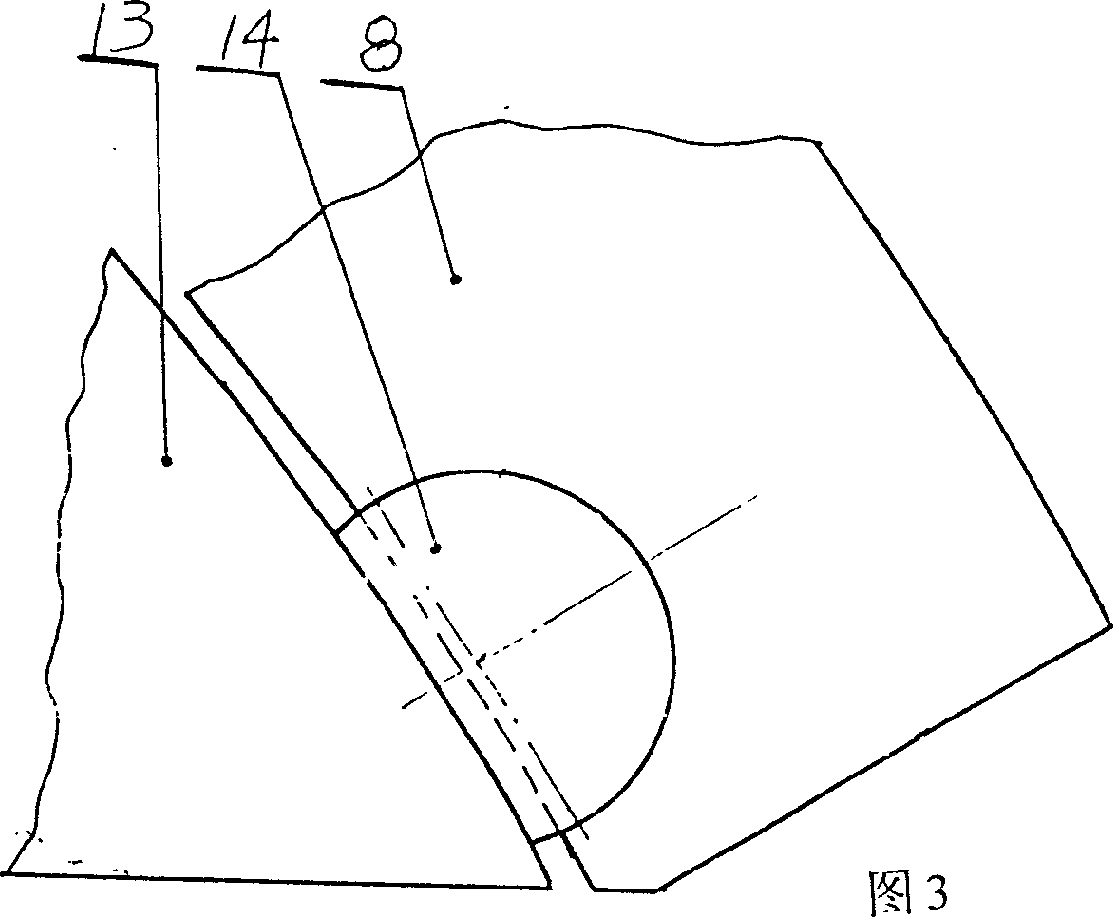

[0027] figure 1 It is a collet in the prior art. In the collet shell 5, there are two gripper bodies with shanks interlaced and inserted into the shell 5. The gripper arm 3 at the left end of the gripper body extends out of the shell 5, and the end is installed with The front jaw 1; the up and down movement of the two front jaws 1 to clamp the blank is achieved by the cooperation of the cylinder 4 in the middle of the respective jaw arm 3 and the arc handle 8 and the concave cylindrical surface 6 on the left wall of the shell 5. Realized, the handles of the upper and lower jaw bodies are arc-shaped handles 8 that are relatively curved upward and downward from the right side of the cylinder 4; 11. The wedge-shaped block 13 fixed at its lower part faces the inner curved surface of the arc-shaped handle 8, and the pull plate 11 on the top surface of the arc-shaped handle 8 is fixed with a guide block 10 guiding the arc-shaped handle 8, and the rear part of the pull plate 11 is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com