Ring spinning method and device of equi-linear density space dyed yarn

A technology of linear density and ring spinning, which is applied to spinning machines, textiles, papermaking, and drafting equipment, etc. It can solve problems such as poor color fastness to dyeing, uniformity of yarn evenness, and many processes, and achieve yarn The effect of uniform density, consistent drafting area and synchronous adjustable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Spinning frame refers to cotton type, wool type spinning frame or roving frame with roller drafting mechanism.

[0021] A fiber sliver is a roving sliver or a drawn finish sliver.

[0022] The original three-roller drafting device of the spinning machine can be replaced with the original four-roller drafting device of the spinning machine, and the corresponding three-axis four-roller segment color spinning device can be replaced with a four-axis five-roller segment color spinning device.

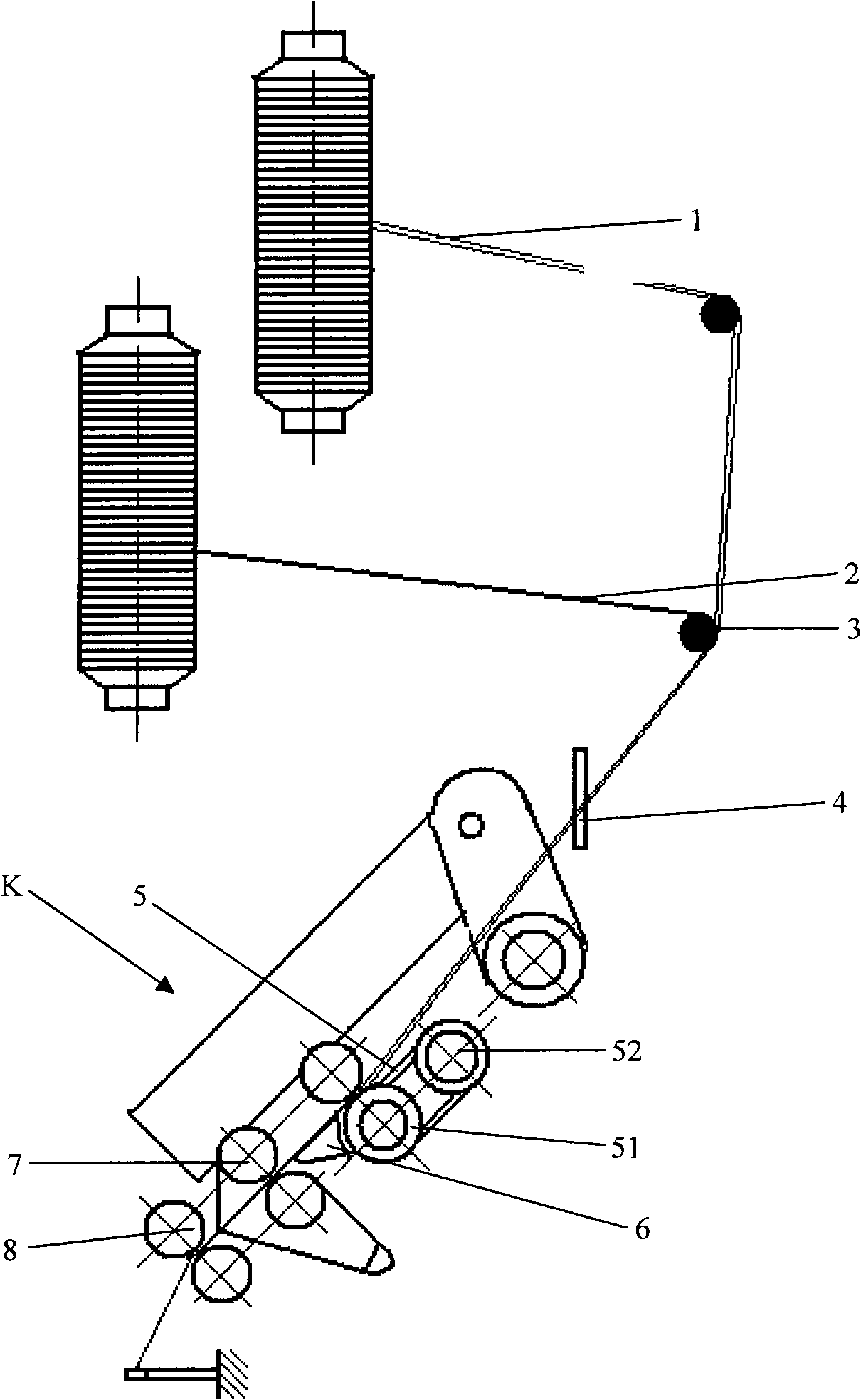

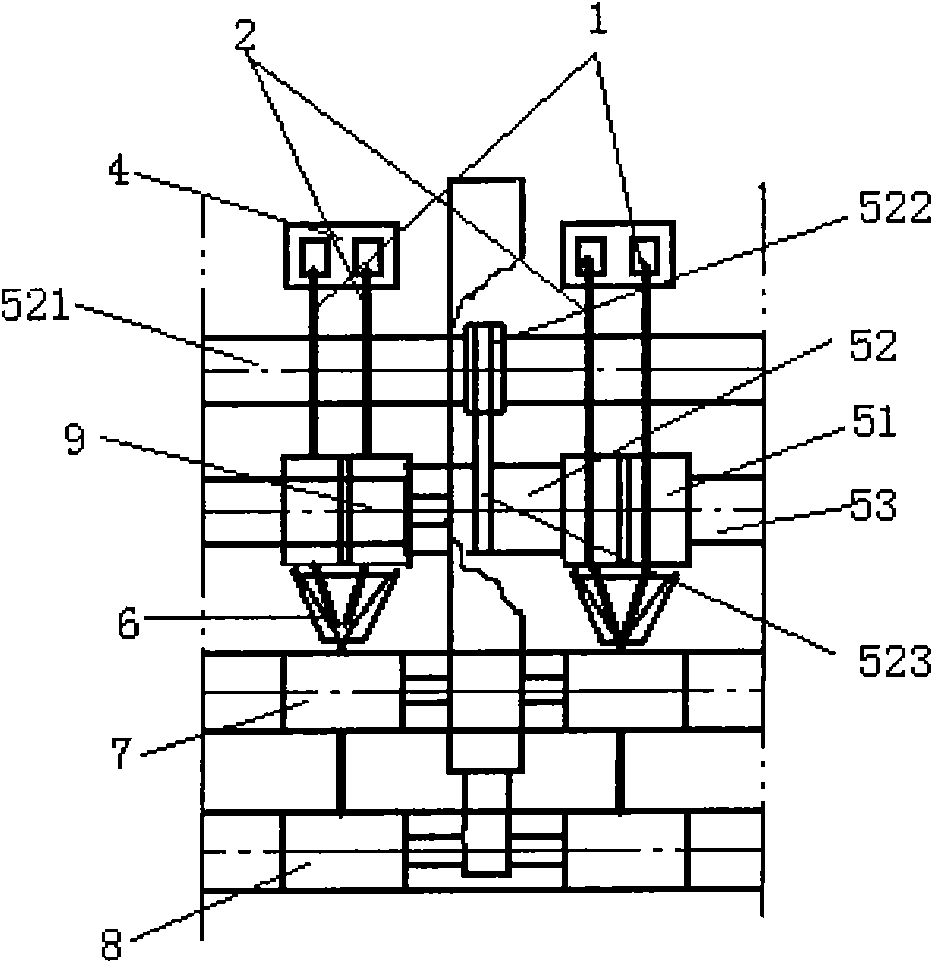

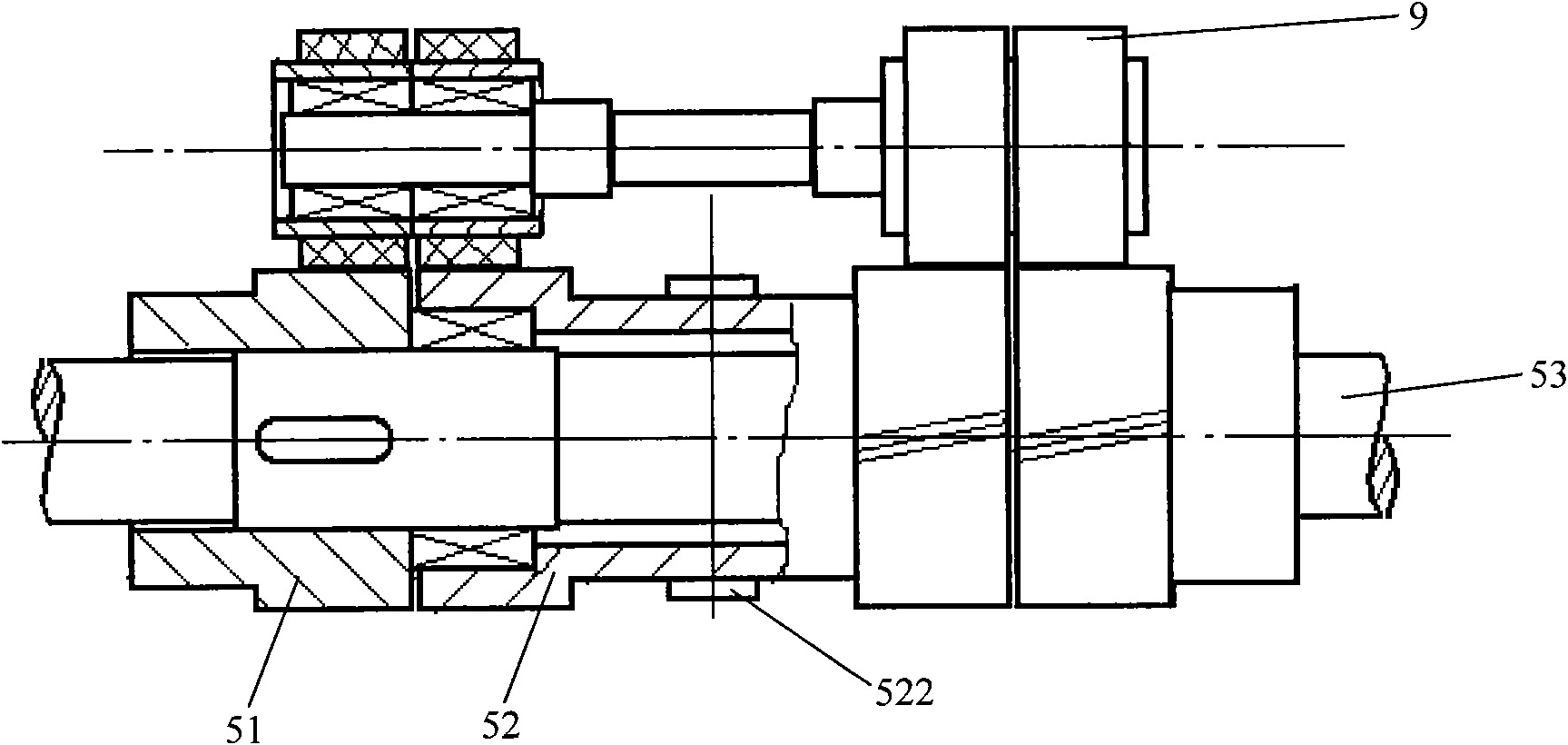

[0023] Such as figure 1 and figure 2 As shown, in the method for forming colored yarns of equal linear density ring spinning segments of the present invention, the fiber strips 1 of group A and the fiber strips of group B 2 are respectively fed to the rear roller 5 through the yarn guide rod 3 and the grid 4, respectively. The fixed rear roller 51 and the looper rear roller 52 on the rear roller 5 axis are controlled, fed to the middle roller 7 through the sliver collector 6 at dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com