Rubber composition for color truck radial tire tread

A radial tire and rubber composition technology, which is applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as difficult mixing, unsatisfactory physical and mechanical properties of rubber materials, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, natural rubber, rare earth butadiene rubber and styrene-butadiene rubber are used in combination as the base rubber. Each component of the composition of the embodiment is measured in parts by mass, and the specific components are shown in Table 1. The kneading of the rubber composition can be carried out by methods known to those skilled in rubber kneading. For example, each component is generally mixed in at least two stages. The mixing process of the rubber composition is to use a closed rubber mixer to masticate the raw rubber for 3 to 4 minutes, and the temperature is in the range of 160 to 170 ° C. Glue removal to complete the preparation of a section of plasticized rubber; after the film is parked for 8 hours, add a section of plasticized rubber, synthetic rubber, highly dispersible white carbon black and all compounding agents except the vulcanization system into the closed rubber mixer, and mix Refining for 3 to 4 minutes, discharge the glu...

Embodiment 2

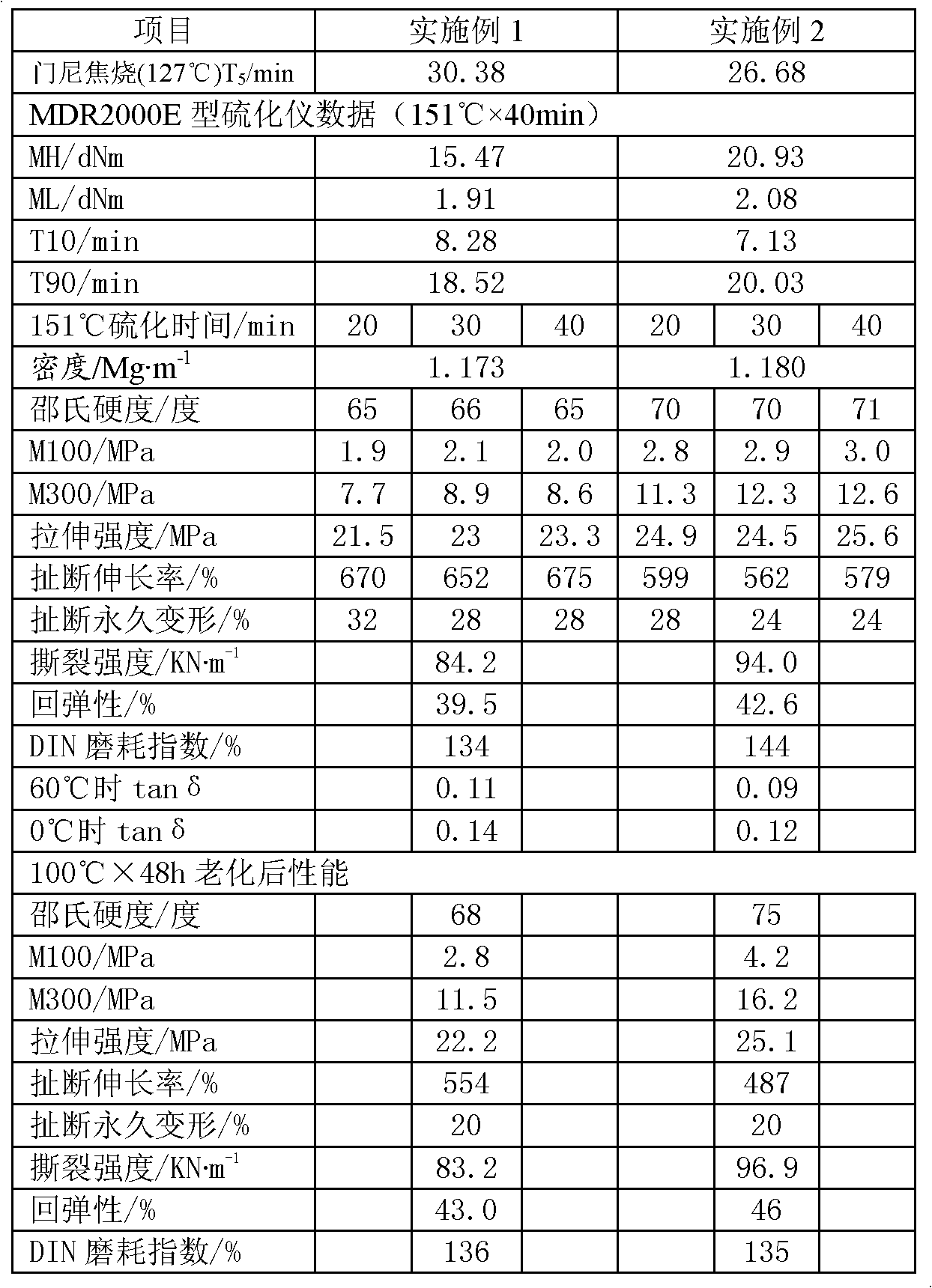

[0041] In this embodiment, natural rubber and rare earth butadiene rubber are used together as the base rubber. The mixing method is as in Example 1. After the mixed rubber material is parked for 6 hours, the samples are vulcanized by a steam plate vulcanizer at a temperature of 151°C for 20 min, 30 min, and 40 min respectively. Carry out various performance tests according to the corresponding national standards.

[0042] Table 1

[0043] raw material

Example 1

Example 2

RSS3#

65

80

Rare earth butadiene rubber

20

20

SBR1502E

15

--

5.5

5.5

Highly dispersible silica

70

70

Liquid silane coupling agent Si-69

5.8

5.8

light rubber oil

8

8

Processing aids

4

4

Antiaging agent

5

5

Vulcanizing agent

1

1

Accelerator

3

3

other

10

10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com