Method for preparing porous nitrogen-contained carbon fiber electrode material from melamine resin/polyvinyl alcohol aqueous solution through high-pressure static spinning technology

A high-voltage electrospinning and melamine technology, which is applied in the direction of spinning solution preparation, fiber treatment, electrolytic capacitors, etc., can solve the problems of high cost, complicated operation, and environmental pollution, and achieve low cost, simple operation, and little environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

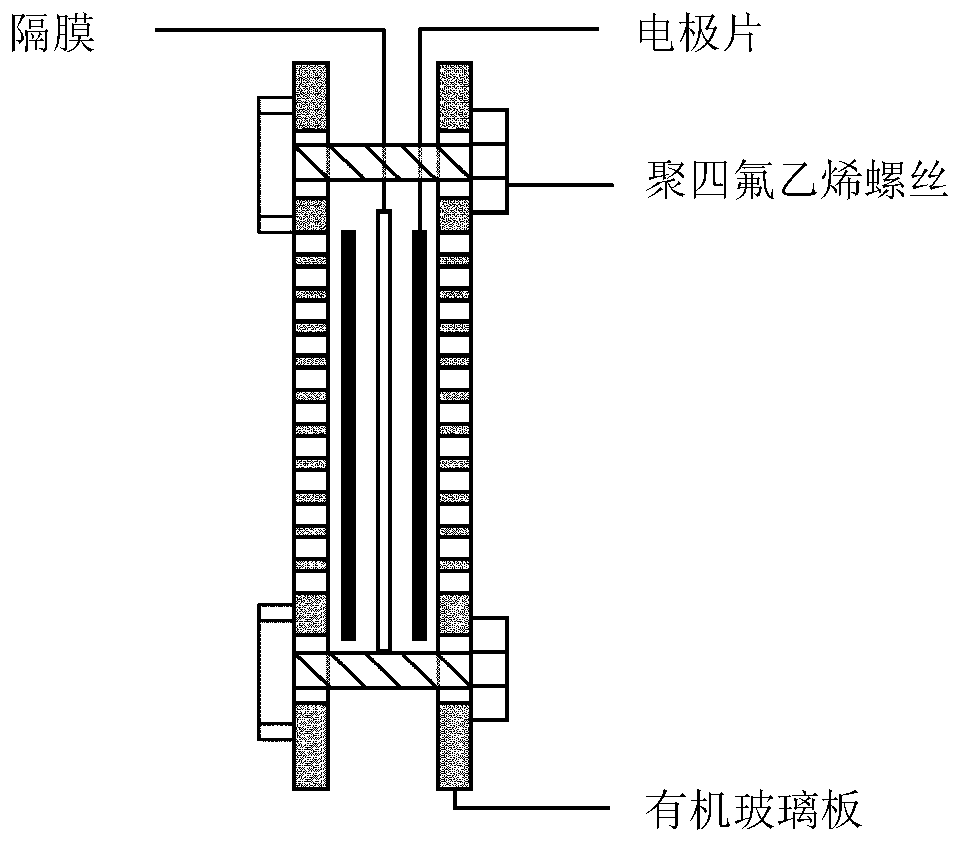

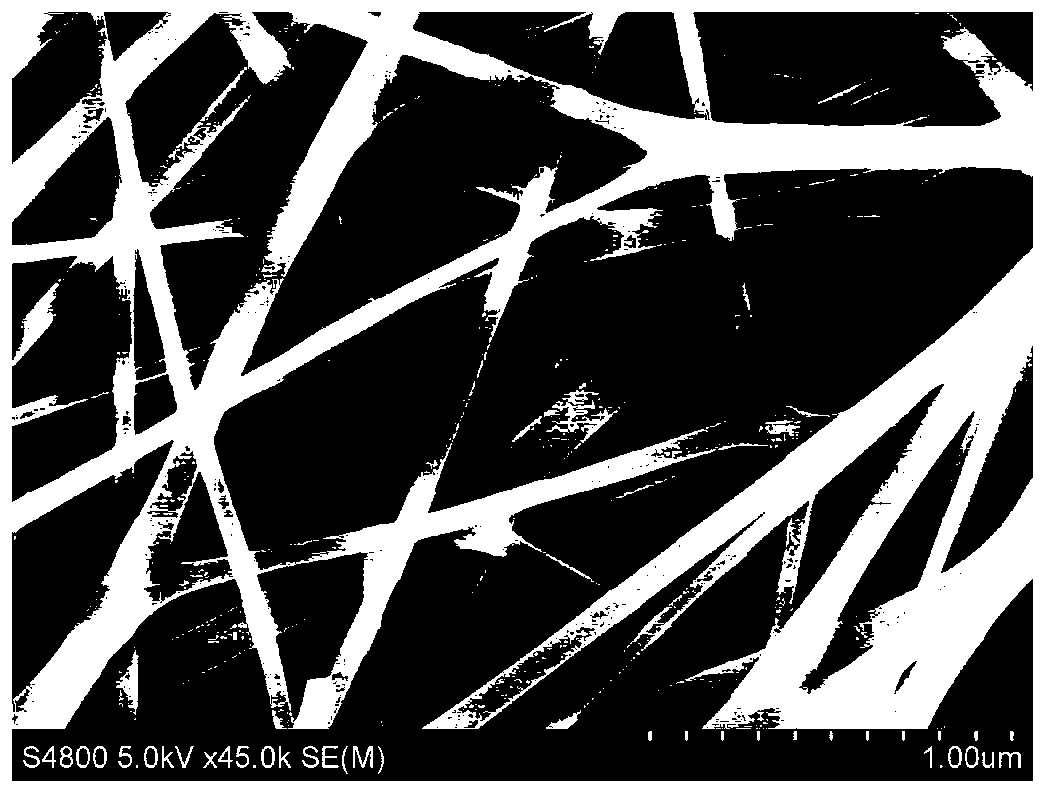

[0021] Specific embodiment one: the melamine resin / polyvinyl alcohol aqueous solution of the present embodiment prepares the method for porous nitrogen-containing carbon fiber electrode material through high-voltage electrospinning technology, is realized through the following steps:

[0022] 1. Mix the polyvinyl alcohol aqueous solution and the melamine resin aqueous solution at a volume ratio of 1:0.2-5, then add the pore-forming agent to the mixed solution, and stir it evenly with a magnetic stirrer at room temperature to obtain the spinning stock solution; Wherein melamine resin is the abbreviation of melamine resin formaldehyde resin; the mass percentage concentration of polyvinyl alcohol in the polyvinyl alcohol aqueous solution is 10%~30%, the mass percentage concentration of melamine resin in the melamine resin aqueous solution is 30%~50%, pore forming agent It is a water-soluble ammonium salt with a concentration of 0.5% to 7% of the total mass of polyvinyl alcohol and...

specific Embodiment approach 2

[0025] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the volume ratio of polyvinyl alcohol aqueous solution and melamine formaldehyde resin aqueous solution is 1:2 in step one. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Specific embodiment three: what this embodiment is different from specific embodiment one or two is: the mass percentage concentration of polyvinyl alcohol in the polyvinyl alcohol aqueous solution is 20% in the step 1, the mass percentage concentration of melamine formaldehyde resin in the melamine formaldehyde resin aqueous solution 40%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com